228

9 MANUFACTURER FUNCTIONS

9.5 Simple cam function

Operation

• Execute operation so that the machine speed of the input axis is equal to or less than "[Cam control data

No. 48 - Cam axis length per cycle] × 1/2 × 1000 [command unit/s]". Failure to do so may cause the input

axis and output axis to become out of synchronization.

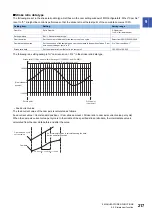

A rotary knife system is shown as an example of the operation of the simple cam function.

Configuration example

The rotary knife cuts the sheet conveyed by the conveyor at a constant speed into a desired length.

The cutting positions are compensated based on detection of the registration marks printed on the sheet to prevent variations

in the sheet length and deviations in cutting position.

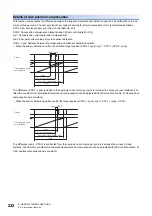

*1 Set the machine speed of the input axis to a value that satisfies the following equation.

Machine speed

≤

[Cam control data No. 48 - Cam axis length per cycle] × 1/2 × 1000 [command unit/s]

To check the machine speed, monitor the main axis current value with the graph function of MR Configurator2.

The machine speed is calculated as follows:

Machine speed = (L2 - L1)/(T2 - T1)

MR-J4-GF-RJ

Servo amplifier

A/B-phase output

Touch probe

Machine

speed

*1

Rotary knife axis

Synchronous encoder

Servo motor for driving the cam axis

Conveyor axis

Drives the conveyor using an inverter or

other servo amplifier

T2

T1

L1

L2

Main axis current value

Time