216

9 MANUFACTURER FUNCTIONS

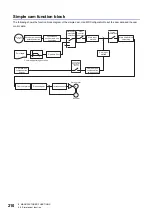

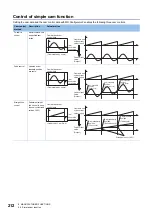

9.5 Simple cam function

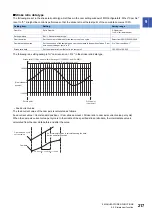

Cam data

• If the cam data is set incorrectly, the position command and speed command may increase, causing

machine interference or [AL. 31 Overspeed]. When you have created and changed cam data, make sure to

perform test operations and make appropriate adjustments.

The following two types are available for the cam data.

Cam data type

Description

Stroke ratio data type

Cam curve of one cycle is divided equally by the number of cam resolution and defined.

The cam curve will be created according to the stroke ratio data of the number of cam resolution.

Coordinate data type

Data in which cam curve of one cycle is defined with two or more points. The coordinate data is defined as (input value,

output value). The input value will be the cam axis current value per cycle, and the output value will be the stroke value

from the cam standard position.