7A-26

ENGINE ATTACHMENTS

90-13645--2

495

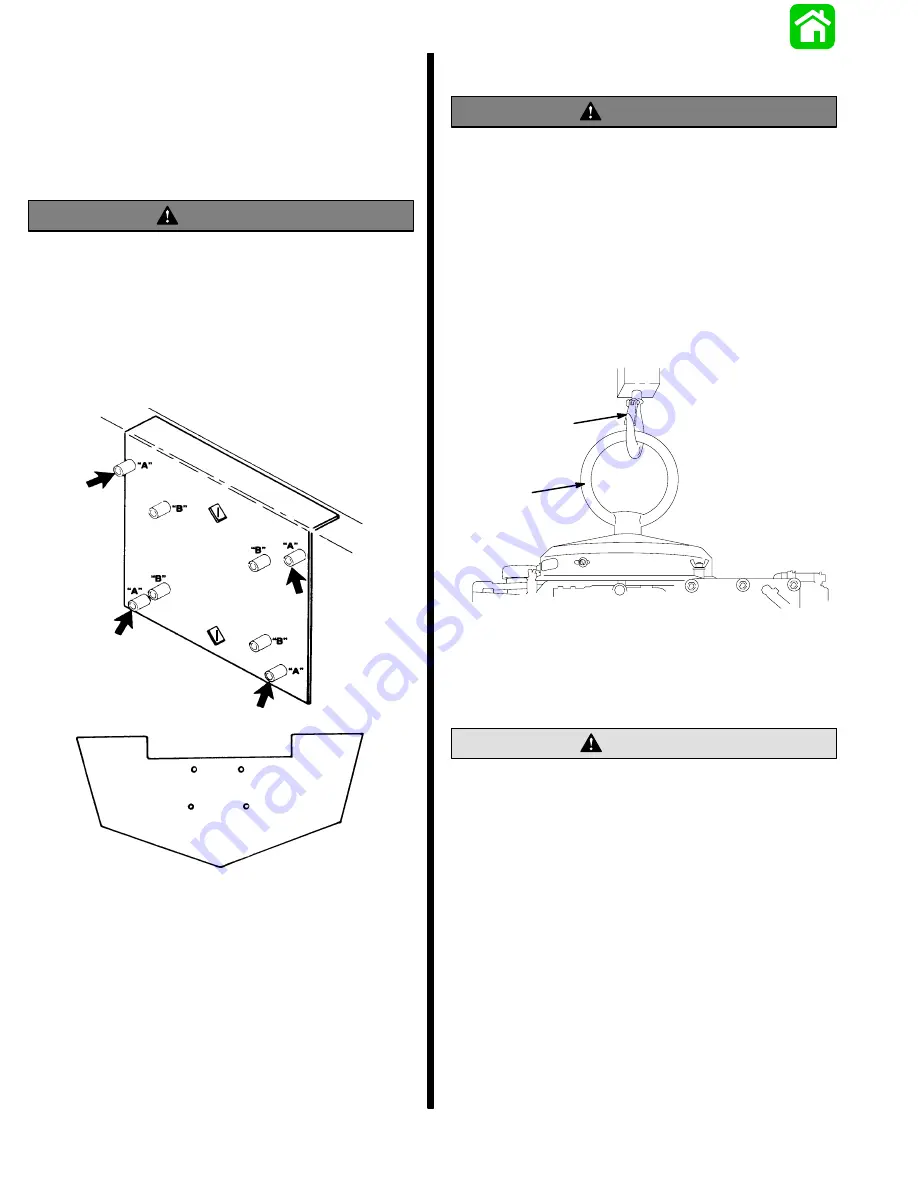

Drilling Outboard Mounting Holes

IMPORTANT: Before drilling any mounting holes,

carefully read “Determining Recommended Out-

board Motor Mounting Height”, preceding. There

is a 3/4 in. (19mm) difference between outboard

mounting holes in transom bracket.

WARNING

DO NOT, under any circumstances, allow upper

outboard mounting bolts to be closer than 1 in.

(25.4mm) from top of boat transom. Upper

mounting bolts must never be installed thru

shims.

IMPORTANT: If using “Transom Drill Fixture”

(91-98234A2), use drill guide holes marked “A”

when drilling outboard mounting holes.

Lifting Engine

WARNING

Make sure that lifting eye is threaded into flywheel

a minimum of 5 turns and that hoist has a

minimum lift capacity of at least 500 lbs. (227 kg)

BEFORE lifting engine.

1. Remove cowling from engine and plastic cap from

center of flywheel. Thread lifting eye into flywheel

hub a minimum of 5 turns. Replace plastic cap af-

ter installation.

2. Connect hoist [minimum lift capacity of 500 lbs.

(227 kg)] to lifting eye. Lift engine and place on

boat transom.

25929

a

b

a - Lifting Eye (C-91-75132)

b - Hoist

Installing Engine to Transom

Marine sealer must be used on shanks of

mounting bolts to make a water-tight installation.

CAUTION

NOTE: Because of clearance on some boats it will be

necessary to install steering cable on engine before

installing engine to transom. Refer to page 1 of this

instruction.

IMPORTANT: DO NOT use an impact driver when

tightening transom mounting bolts.

1. Determine engine mounting height dimension

from graph (STEP 1) and use engine mounting

holes that will position engine nearest to recom-

mended height.

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...