7A-22

ENGINE ATTACHMENTS

90-13645--2

495

Normal Service – Every 50 hrs. of operation or 60

days (whichever comes first)

*Severe Service – Every 25 hrs. of operation or 30

days (whichever comes first)

*

Operation in a salt water area is considered “Severe Service.”

1. Carefully check steering system components for

wear. Replace worn parts.

2. Check steering system fasteners to be sure that

they are torqued to correct specifications.

Ride-Guide steering cables are lubricated at the fac-

tory and require no additional lubrication at initial

installation.

WARNING

Core of each steering cable (transom end) must

be fully retracted into cable housing before

lubricating cable. If cable is lubricated while

extended, hydraulic lock could occur.

3. With core of Ride-Guide steering cable (transom

end) fully retracted, lubricate transom end of

steering cables thru grease fittings with 2-4-C w/

Teflon. Lubricate exposed portion of cable ends

with 2-4-C w/Teflon.

4. Lubricate pivot point of steering link rod and ball

joint of link rod/steering coupler with SAE 30W

Motor Oil.

5. Inspection and lubrication of steering head

assembly (rotary or straight rack) should be

performed once each year (by your Authorized

Dealer) or whenever steering mount and/or

steering head are disassembled, or if steering

effort has increased. Lubricate with 2-4-C

w/Teflon.

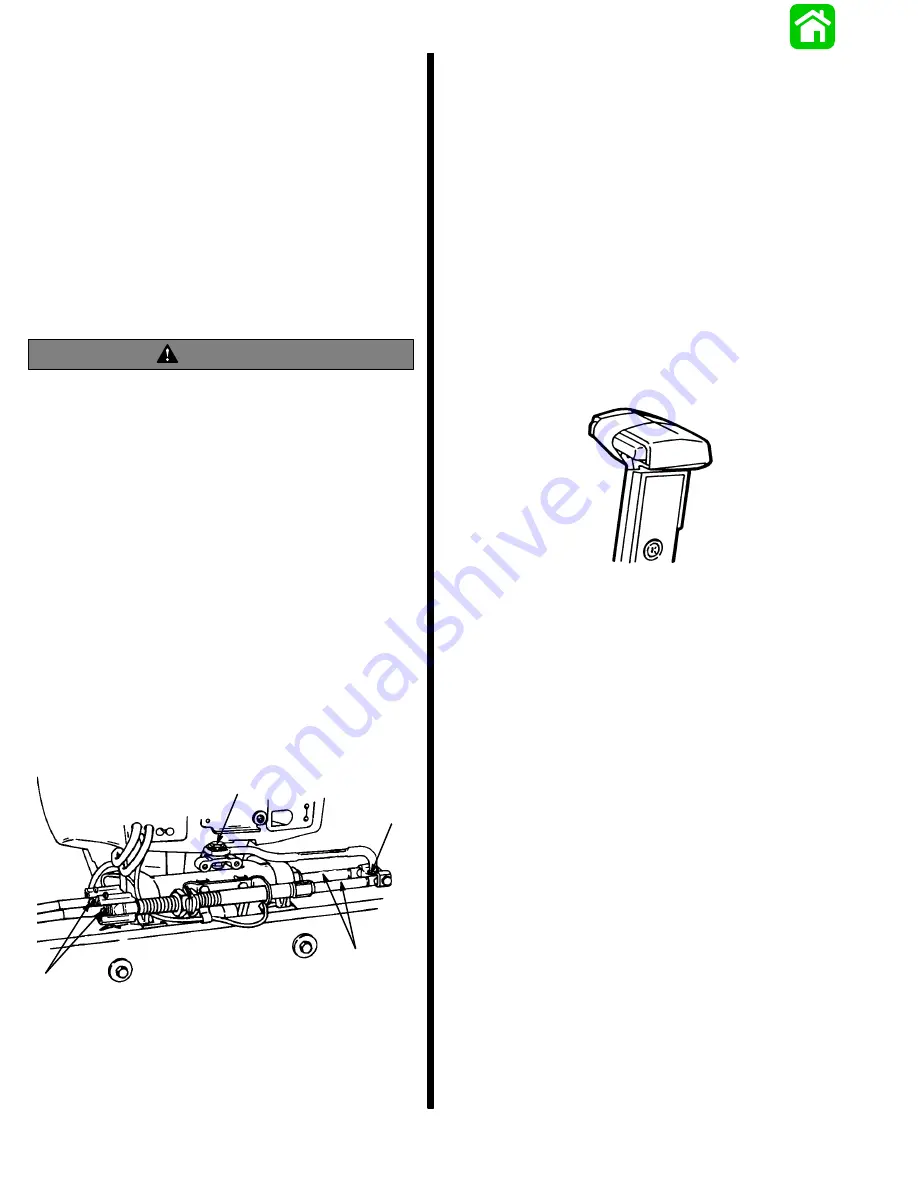

50135

a

b

d

c

a - Grease Fitting

b - Cable Ends

c - Pivot Point

d - Ball Joint

Remote Control Installation

Shift Cable Installation and

Adjustment to Engine

IMPORTANT: Install control cables to remote con-

trol and mount remote control BEFORE attaching

control cables to engine.

NOTE: Attach shift cable to engine first. Shift cable is

the first cable to move when remote control handle is

advanced from neutral position toward in-gear

position.

If remote control has a neutral lock release, secure

the release in the depressed position using a piece of

tape, as shown. Now you can locate the true neutral

detent.

22752

NOTE: Rotate remote control handle back and forth.

You will feel three detent positions; center detent is

neutral.

1. Position remote control handle in neutral detent.

2. Manually shift engine into neutral (propeller will

rotate freely).

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...