6B-34

90-13645--2

495

POWER TRIM

Reassembly - Motor and Pump

NOTE: Driveshaft is a loose part and may fall out of

position.

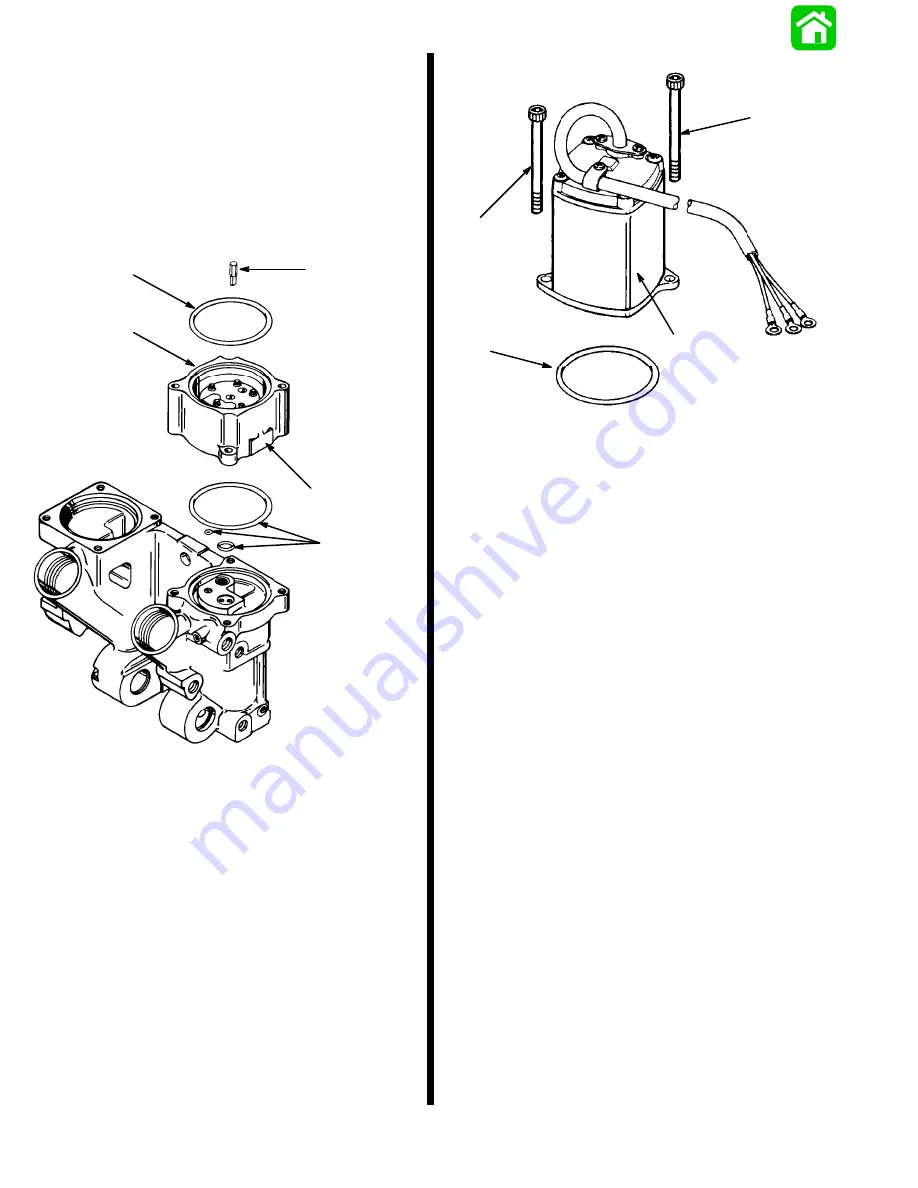

1. Install pump onto power trim manifold. Insure

O-rings are in proper locations. Secure with two

(2) screws. Torque screws to 70 lb. in. (7.9 N·m).

IMPORTANT: Install pump with location flat facing

towards starboard transom bracket.

51433

a

b

c

d

c

a - Pump (Flat towards starboard transom bracket)

b - Flat (Faces starboard transom bracket)

c - O-rings (4)

d - Driveshaft (Install in center hole in pump)

2. Fill pump with Quicksilver Power Trim and Steer-

ing Fluid prior to installing motor.

3. Install motor, secure with two (2) screws. Route

wiring; refer to Wiring Diagrams in this service

manual. Torque screws to 70 lb. in. (7.9 N·m).

NOTE: Insure motor and driveshaft are aligned.

51433

a

b

c

c

a - Motor

b - O-ring

c - Screw (2) - Torque screws to 70 lb. in. (7.9 N·m)

4. Complete reassembly of Power Trim System as

outlined in “Installation” on page 6B-15 and

6B-16.

Priming Power Trim System

1. Fill system with Quicksilver Power Trim and Steer-

ing Fluid or Automatic Transmission Fluid (ATF)

Type F or FA. Refer to “Fill, Check, and Purge”

on page 6B-5.

IMPORTANT: Run Trim System in short “jogs”

until pump motor primes and trim system moves.

If trim motor is run without priming pump,

driveshaft failure could result.

Trim Sender (Optional Accessory) Test

1. Check trim sender black lead for proper ground.

2. Trim outboard to full “DOWN” position.

3. Place ignition switch to “ON” position.

4. Connect Ohmmeter (R x 1 scale) leads between

outboard ground and Point 1.

5. Depress “UP” button. Ohmmeter needle should

move as the outboard is trimmed up. If needle

does not move, trim sender is defective.

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...