6C-2

90-13645--2

495

POWER-TRIM

Improves planing speed acceleration (by moving tilt

bolt one hole closer to transom).

Operating “Down” circuit will actuate the “down” relay

(located under engine cowl) and close the electric

motor circuit (motor will run in opposite direction of the

“Up” circuit). The electric motor will drive the pump,

forcing fluid thru internal passageways into the

“down” side of the tilt ram. The tilt ram will move the

engine down to the desired angle.

Trailering Outboard

WARNING

Excessive engine trim angle will result in

insufficient water supply to water pump causing

water pump and/or powerhead overheating

damage. Make sure that water level is above gear

housing water intake holes whenever engine is

running.

While operating “up” circuit, the ram will continue to tilt

outboard to full up position for trailering.

Tilting Outboard Up and Down

Manually

WARNING

Before opening the manual release valve, make

sure all persons are clear of engine as engine will

drop to full “down” position when valve is

opened.

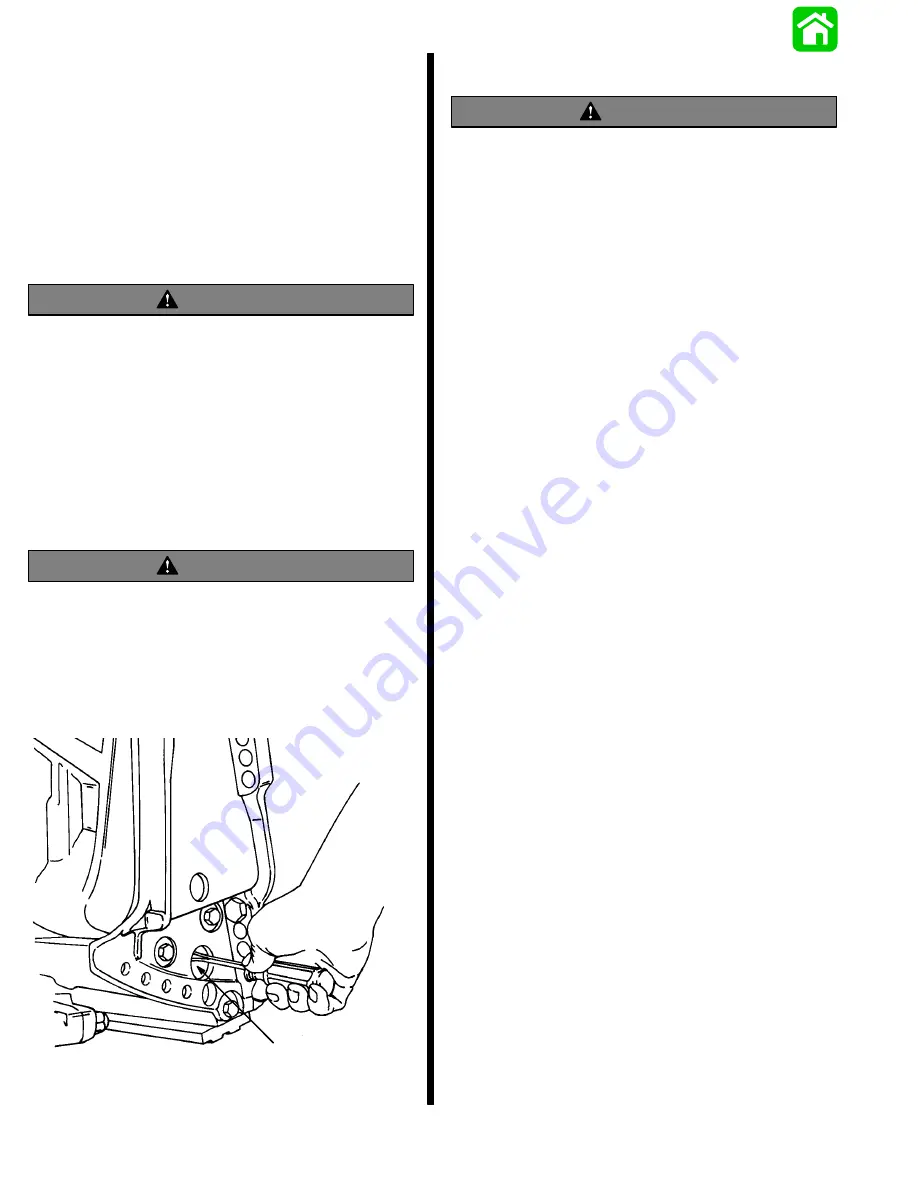

With power trim installed, the outboard can be raised

or lowered manually by opening the manual release

valve 3 turns maximum (counterclockwise).

51432

a

a - Manual Release Valve

Trim “In” Angle Adjustment

WARNING

Operating some boats with engine trimmed to the

full “in” trim angle [not using trim adjustment bolt]

at planing speed will cause undesirable and/or

unsafe steering conditions. Each boat must be

water tested for handling characteristics after

engine installation and after any trim

adjustments.

IMPORTANT: Some boat/motor combinations,

that do not use the trim adjustment bolt and are

trimmed to the full “in” trim angle, will not experi-

ence any undesirable and/or unsafe steering con-

ditions during planing speed. Thus, not using trim

adjustment bolt may be desired. However, some

boats with engine trimmed to the full “in” trim

angle at planing speed will cause undesirable

and/or unsafe steering conditions. If these steer-

ing conditions are experienced, under no circum-

stances should the engine be operated without

the trim adjustment bolt and without the bolt ad-

justed in the proper holes to prevent unsafe han-

dling characteristics.

Water test the boat not using the trim adjustment bolt.

If undesirable and/or unsafe steering conditions are

experienced (boat runs with nose down), install trim

adjustment bolt in proper hole to prevent unsafe han-

dling characteristics.

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...