4A-32

90-13645--2

395

POWERHEAD

IMPORTANT: On some engines, BOTH the piston

rod and rod cap bolt holes are threaded. The rod

cap and rod must be aligned and held tight

together when threading in bolt. Check that

mating surfaces are tight together after bolt

enters the threads in the piston rod.

20033

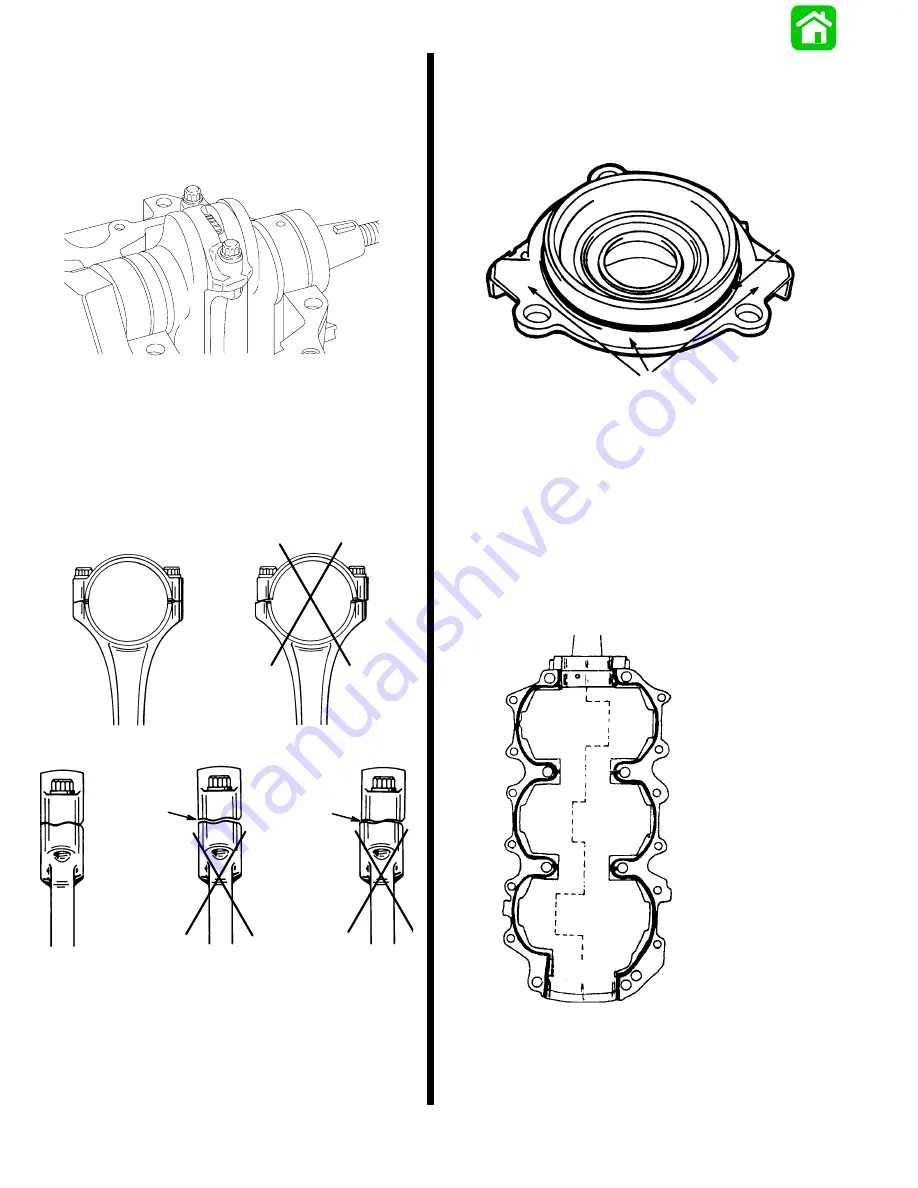

Connecting Rod Cap Alignment

1. Check each connecting rod for correct alignment

by carefully running fingernails up and down edge

of rod cap. If not aligned, a ridge can be seen or

felt at the separating line. Correct any misalign-

ment.

Front View

Correct

Front View

Incorrect

Side View

Correct

Side View

Incorrect

Side View

Incorrect

Space

Ridge

51224

2. When connecting rods are attached, and bolts

drawn down finger tight, torque rod-cap bolts to

15 lb. in. (1.7 N

m). Recheck alignment. Retorque

1/4 in. bolts to 15 lb. ft. (20.3 N

m) or 5/16 in.

bolts to 30 lb. ft. (40.7 N

m). Recheck alignment.

Turn each rod-cap bolt 90

_

further after 30 lb. ft.

reading is acquired.

S

Replace lower crankshaft End Cap.

1. Coat mating surface with Perfect Seal. DO NOT

coat O-ring seal.

2. Bolt to block (2 bolts) - finger tighten - lightly.

19336

a

b

a - Mating Surface

b - O-ring Seal

Crankcase Cover to Block

LOCTITE MASTER GASKET SEALANT,.

92-12564-1 is used; it comes as a kit, which includes

Primer and Sealant. Instructions contained in the kit

MUST BE FOLLOWED EXACTLY. (Clean both sur-

faces).

IMPORTANT: Extend sealer to edge on each center

main journal to prevent blow-by between cylinders.

Sealant “Bead Pattern”

indicated by bold line.

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...