7A-21

ENGINE ATTACHMENTS

90-13645--2

495

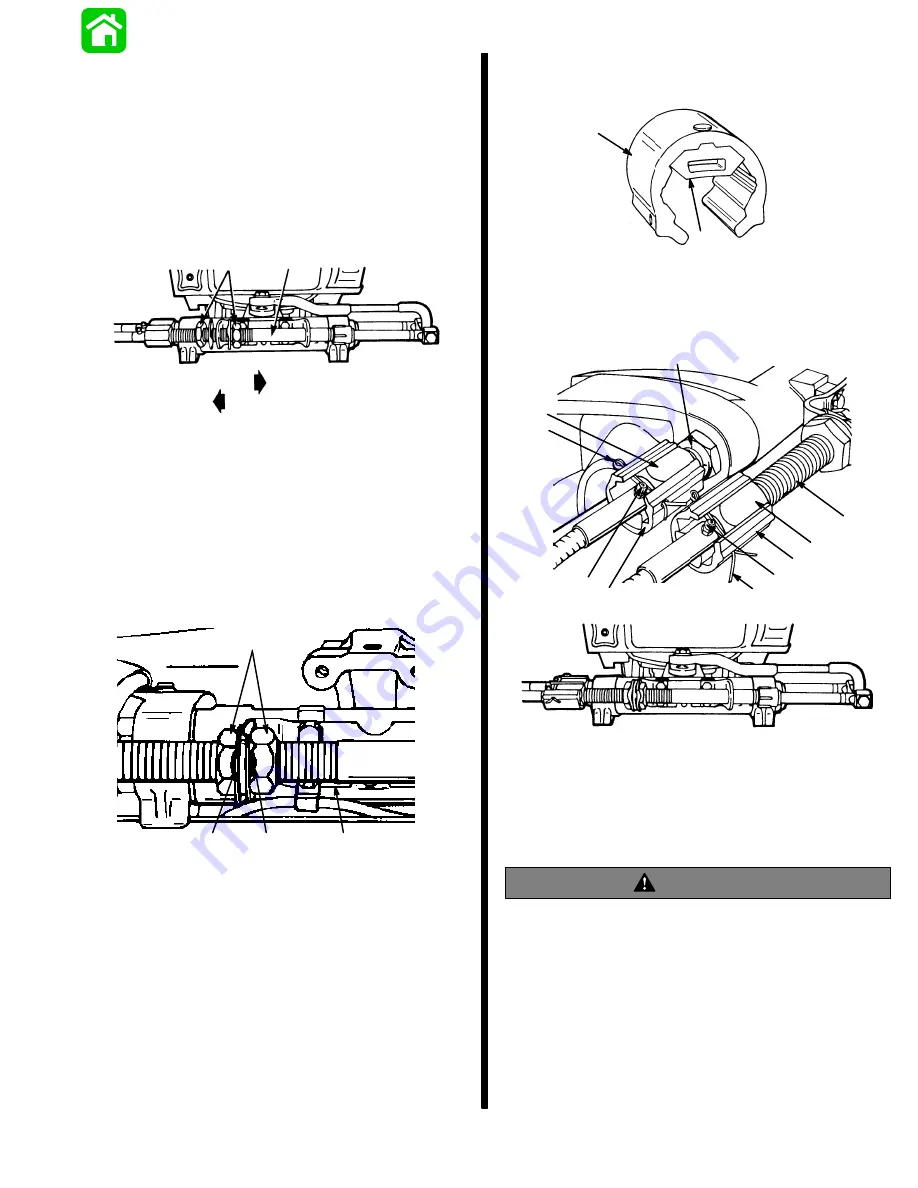

Loosen adjustment nuts and pull steering cable

mounting tube (by hand) away from end of steering

cable (to remove slack in steering system). Tighten

adjustment nuts against mounting bracket and check

system for slack (play). If steering system is too tight,

readjust tube toward end of steering cable or, if too

much slack (play) exists in system, readjust tube

away from end of steering cable. Tighten nuts against

mounting bracket and readjust, if necessary.

a

b

c

d

16961

a - Steering Cable Mounting Tube

b - Adjustment Nuts

c - Adjust Tube in This Direction to Remove Slack from Steering

System.

d - Adjust Tube in This Direction to Reduce Tension from

Steering System.

After steering system tension is adjusted correctly,

tighten adjustment nuts against mounting bracket, to

a torque of 35 Ib. ft. (47.4 N

m) and bend a tab lock

washer against a flat on each nut.

51887

a

b

c

c

a - Steering Cable Mounting Tube

b - Adjustment Nuts; Torque to 35 lb. ft. (47.4 N

m)

c - Tab Lock Washer (Bend Against Flat on Each Adjustment

Nut)

Tighten steering cable attaching nuts of each steering

cable to a torque of 35 Ib. ft. (47.4 N

m).

Install rubber bumpers (a) on inside of each locking

sleeve (b).

a

b

51889

Install locking sleeves over steering cable attaching

nuts and secure with cotter pins. Spread ends of cot-

ter pins. Be sure to install cotter pin so that it is located

in between attaching nut and grease fitting.

d

51890

a

b

c

e

c

a

b

d

f

51452

a - Steering Cable Attaching Nut - Torque to 35 lb. ft. (47.4 N

m)

b - Locking Sleeve (If So Equipped)

c - Cotter Pin

d - Grease Fitting

e - Steering Cable Mounting Tube

f - Outboard Tilt Tube

WARNING

After installation is complete (and before operating

outboard(s), check that boat will turn right when

steering wheel is turned right and that boat will turn

left when steering wheel is turned left. Check

steering thru full range (left and right) at all tilt

angles to assure interference-free movement.

Maintenance Instructions

Maintenance inspection is owner’s responsibility and

must be performed at intervals specified, following:

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...