4A-22

90-13645--2

495

POWERHEAD

S

Use a bristle brush and carbon remover solution to

remove carbon from side surfaces.

S

A tool can be made for cleaning the inner diameter

of the tapered ring grooves. The tool can be made

from a broken tapered piston ring with the side ta-

per removed to enable inside edge of the ring to

reach the inside diameter of the groove. Carefully

scrape the carbon from inner diameter of ring

grooves. Care must be taken not to damage the

grooves by scratching the surfaces of the grooves.

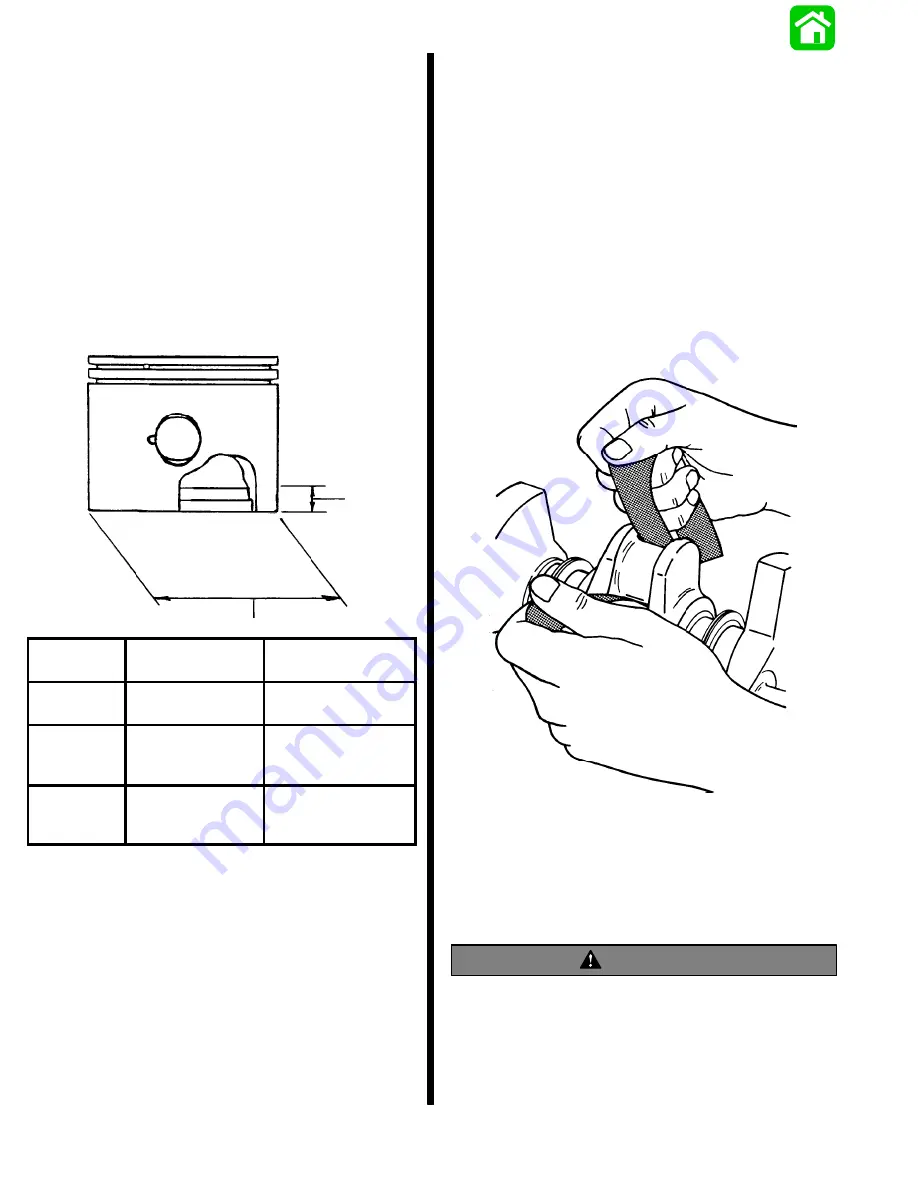

MEASURING PISTON SKIRT

Measure piston skirt at right angle (90

_

) to piston pin

centerline, 0.50 in. (12.7mm) up from bottom edge of

skirt.

.50 in.

(12.7mm)

PISTON

SIZE

PISTON SKIRT

DIAMETER

CYLINDER BORE

FINISH HONE

Standard

Piston

3.371 in.

(85.623mm)

3.375 in.

(85.725mm)

0.015 in.

(0.381mm)

Oversize

3.386 in.

(86.004mm)

3.390 in.

(86.106mm)

0.030 in.

(0.752mm)

Oversize

3.401 in.

(86.385mm)

3.405 in.

(86.487mm)

Crankshaft

S

Inspect crankshaft to drive shaft splines for wear.

(Replace crankshaft, if necessary.)

S

Check crankshaft for straightness. Total maximum

runout for crankshaft is 0.006 (0.152mm). Replace

as necessary.

S

Inspect crankshaft oil seal surfaces. Sealing sur-

faces must not be grooved, pitted or scratched.

(Replace as necessary.)

S

Check all crankshaft bearing surfaces for rust, wa-

ter marks, chatter marks, uneven wear and/or

overheating. (Refer to “Connecting Rods.”)

S

If necessary, clean crankshaft surfaces with cro-

cus cloth as shown.

51089

S

Thoroughly clean (with solvent) and dry crankshaft

and crankshaft ball bearings. Recheck surfaces of

crankshaft. Replace crankshaft if surfaces cannot

be properly “cleaned up”. If crankshaft will be re-

used, lubricate surfaces of crankshaft with light oil

to prevent rust. DO NOT lubricate crankshaft ball

bearings at this time.

WARNING

DO NOT spin-dry crankshaft ball bearing with

compressed air.

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...