7A-4

ENGINE ATTACHMENTS

90-13645--2

495

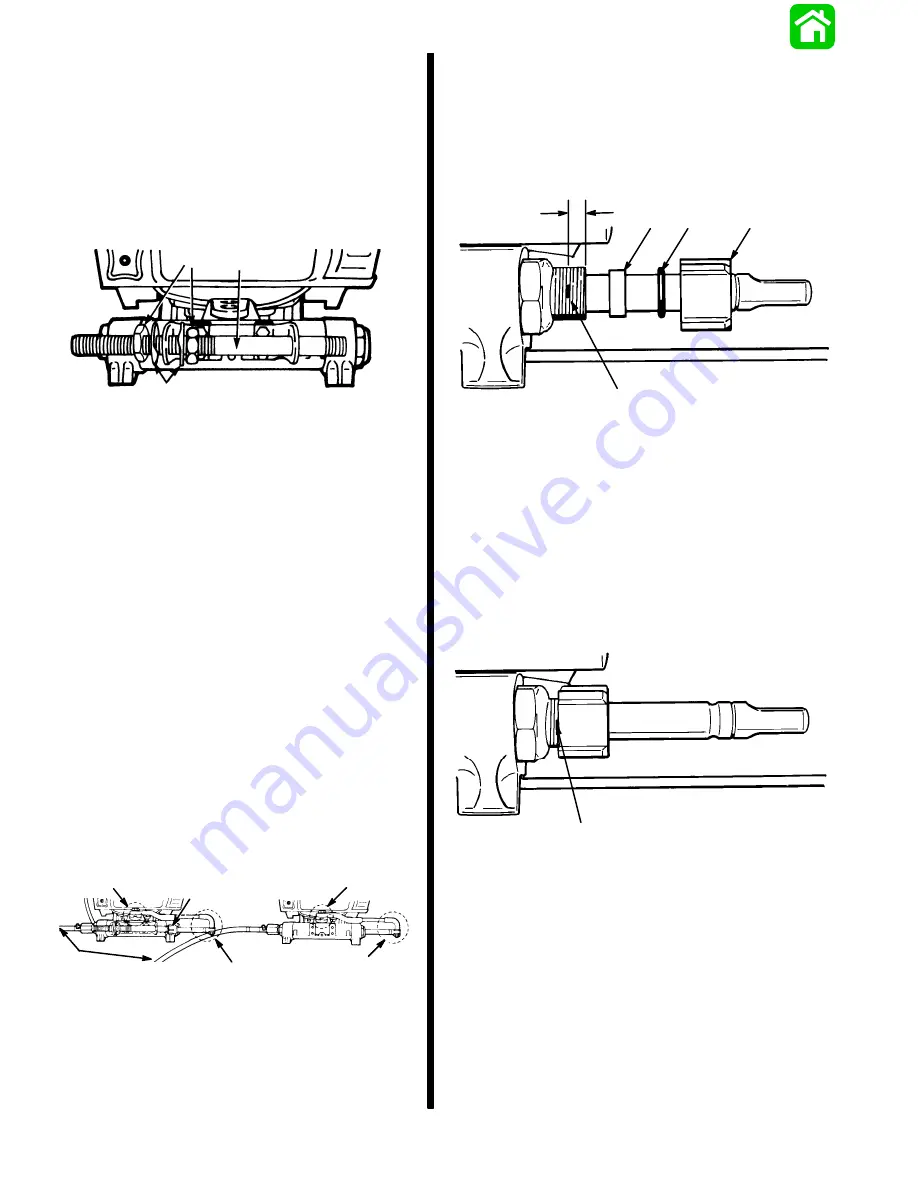

2. Install steering cable mounting tube into mounting

bracket with 2 adjustment nuts and tab lock wash-

ers, as shown in Figure 3. Be sure that longer

threaded end of tube is toward steering cable at-

taching nut side of engine.

3. Temporarily adjust tube so that longer threaded

end of tube is extended out the same distance as

engine tilt tube. Do not tighten adjustment nuts at

this time.

16959

a

b

c

a - Steering Cable Mounting Tube

b - Tab Lock Washers

c - Adjustment Nuts (Rounded Edge Facing Out)

Figure 3. Steering Cable Mounting Tube Installed

4. Install steering cables, as follows:

IMPORTANT: Before installing steering cables, lu-

bricate inside of port mounted engine tilt tube and

inside of steering cable mounting tube with

Quicksilver 2-4-C w/Teflon. Verify that rubber O-

ring seal (located in engine tilt tube) also is lubri-

cated.

a. Lubricate inside of (port) engine tilt tube with

Quicksilver 2-4-C w/Teflon. Make sure that rub-

ber O-ring seal (located in engine tilt tube) also

is lubricated.

b. Lubricate inside of steering cable mounting

tube with Quicksilver 2-4-C w/Teflon.

c. Insert ends of steering cables thru engine tilt

tube and cable mounting tube (Figure 4).

Thread steering cable attaching nuts onto

tubes hand-tight.

a

16977

b

b

c

c

d

a - Steering Cables Routed Down Starboard Side

b - See Figure 7 for Correct Parts Sequence

c - See Figure 8 for Correct Parts Sequence

d - Seal

Figure 4. Steering Cables and Steering Link

Rods Installed

NOTE: Torque steering cables attaching nuts and

install locking sleeve after final tension adjustment.

5. Install steering cable seal to steering cable

mounting tube, as follows:

a. Place a mark on steering cable mounting tube

5/8

″

(15.8mm) from end of tube (Figure 5).

50180

a

b

c

d

e

a - 5/8

″

from End of Tube

b - Place Mark on Tube Here.

c - Nylon Spacer

d - O-ring

e - Cap

Figure 5. Seal Installation Sequence

b. Slide nylon spacer, O-ring and cap (from kit)

over steering cable (Figure 5).

c. Thread cap onto steering cable mounting tube

up to mark (made on tube in Step “a” (Figure 6).

50180

a

a - Mark Made in Step 5a

Figure 6. Steering Cable Seal Installed

6. Install link rods (Figure 4) to engine steering arms.

Fasten each link rod to steering arm onto top side

rear hole with pivot bolt and locknut, as shown in

Figure 7. Torque each pivot bolt to 20 lbs. ft.

(27.1 N

m), then thread locknut onto pivot bolt

and torque nut to 20 lbs. ft. (27.1 N

m).

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...