4A-21

90-13645--2

495

POWERHEAD

3. Clean mating surfaces of crankcase cover and

intake manifold. Install new gaskets.

4. Install intake manifold/reed block assemblies to

crankcase cover. Refer to PAGE 4A-6 for torque

specification and tightening sequence.

5. Install carburetors. Torque carburetor (AIR BOX)

stud nuts to 100 lb. in. (11.3 N

m).

6. Carburetors MUST BE SYNCHRONIZED. Refer

to SECTION 2C for proper procedures.

7. Reinstall air box cover.

8. Reinstall top cowling.

Piston and Piston Rings

IMPORTANT: If engine was submerged while

engine was running, piston pin and connecting

rod may be bent. If piston pin is bent, piston must

be replaced. Piston pins are not sold separately

because of matched fit into piston. If piston pin is

bent, connecting rod must be checked for

straightness (refer to “Connecting Rods” for

checking straightness).

S

Inspect piston for scoring and excessive piston

skirt wear.

S

Check tightness of piston ring locating pins.

Locating pins must be tight.

S

Thoroughly clean pistons. Carefully remove

carbon deposits, with a soft wire brush or carbon

remover solution. DO NOT burr or round off

machined edges.

S

Inspect piston grooves for wear and carbon

accumulation. If necessary, scrape carbon from

piston ring grooves being careful not to scratch

sides of grooves. Refer to procedure for cleaning

piston ring grooves.

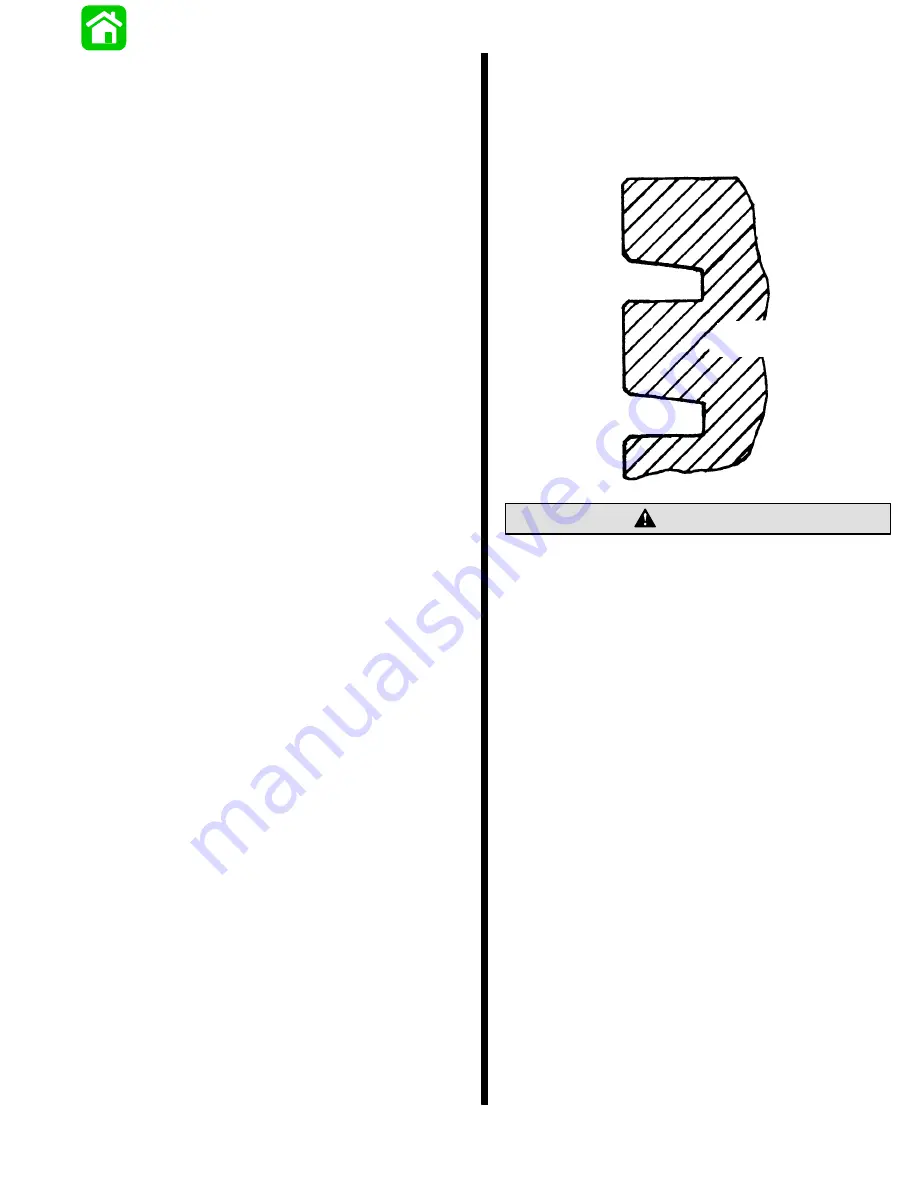

CLEANING PISTON RING GROOVES

IMPORTANT: The piston rings are half-keystone

rings – (tapered on the top side) - follow cleaning

and inspection carefully! Chromed ring is

installed on top.

Enlarged View of

Piston Ring Grooves

Care must be taken not to scratch the side

surfaces of ring groove. Scratching the side

surfaces of the ring groove will cause damage to

the ring groove.

CAUTION

Summary of Contents for 100

Page 4: ...GENERAL INFORMATION AND SPECIFICATIONS 1 ...

Page 18: ...IGNITION SYSTEM ELECTRICAL AND IGNITION A 2 ...

Page 30: ...11669 BATTERY CHARGING SYSTEM AND STARTING SYSTEM ELECTRICAL AND IGNITION B 2 ...

Page 58: ...22480 TIMING SYNCHRONIZING ADJUSTING ELECTRICAL AND IGNITION C 2 ...

Page 71: ...WIRING DIAGRAMS ELECTRICAL AND IGNITION D 2 ...

Page 86: ...FUEL SYSTEM AND CARBURETION A 3 ...

Page 118: ...OIL INJECTION SYSTEM B 3 ...

Page 127: ...20032 3 CYLINDER ENGINES POWERHEAD A 4 ...

Page 168: ...791 H GEAR HOUSING LOWER UNIT A 5 ...

Page 170: ...5A 1 90 13645 2 1095 LOWER UNIT Notes ...

Page 205: ...MID SECTION LOWER UNIT B 5 ...

Page 207: ...5B 1 90 13645 2 495 LOWER UNIT Notes ...

Page 218: ...SHOCK ABSORBER LOWER UNIT C 5 ...

Page 223: ...17250 DESIGN I SIDE FILL RESERVOIR POWER TRIM A 6 ...

Page 233: ...6A 9 POWER TRIM 90 13645 2 495 Commander Side Mount Remote Control Wiring Diagram ...

Page 268: ...DESIGN II AFT FILL RESERVOIR POWER TRIM B 6 51344 ...

Page 305: ...SINGLE RAM POWER TRIM C 6 51485 ...

Page 309: ...6C 3 90 13645 2 495 POWER TRIM Notes ...

Page 340: ...50099 ENGINE ATTACHMENTS ENGINE INSTALLATION 7 A ...

Page 369: ...TILLER HANDLE AND CO PILOT OUTBOARD MOTOR INSTALLATION ATTACHMENTS 7 B ...

Page 371: ...7B 1 90 13645 2 495 OUTBOARD MOTOR INSTALLATION ATTACHMENTS Notes ...