Hardware and Connections

2-13

7SA6 Manual

C53000-G1176-C156-2

Connections to

Current Terminals

Ring-type and fork-type lugs may be used. To ensure that the insulation paths are

maintained, insulated lugs must be used. Alternatively, the crimping area must be in-

sulated with other methods, e.g. by covering with a shrink sleeve.

The following must be observed:

Connections with cable lugs: inner diameter of lugs, 5 mm;

maximum outer diameter of lugs, 12 mm;

conductor with cross-section of 2.6 mm

2

to 6.6 mm

2

(AWG 14 to 10).

Use copper wires only!

Cable lugs of series PIDG from Messrs. Tyco Electronics AMP are recommended, e.g.

Ring cable lug:

PIDG PN 130171–0

Fork lug:

PIDG PN 326865–0

Direct cable connections: solid or stranded conductor with connector sleeve;

conductor with cross-section of 2.6 mm

2

to 3.3 mm

2

(AWG 14 to 12).

When using one single conductor, the conductor end must be inserted such that it will

be drawn into the contact cavity while tightening the screw.

Use copper wires only!

Wire strip length: solid conductor 10 to 11 mm (0.39 to 0.43 in).

Maximum tightening torque: 2.7 Nm (24 in-lb).

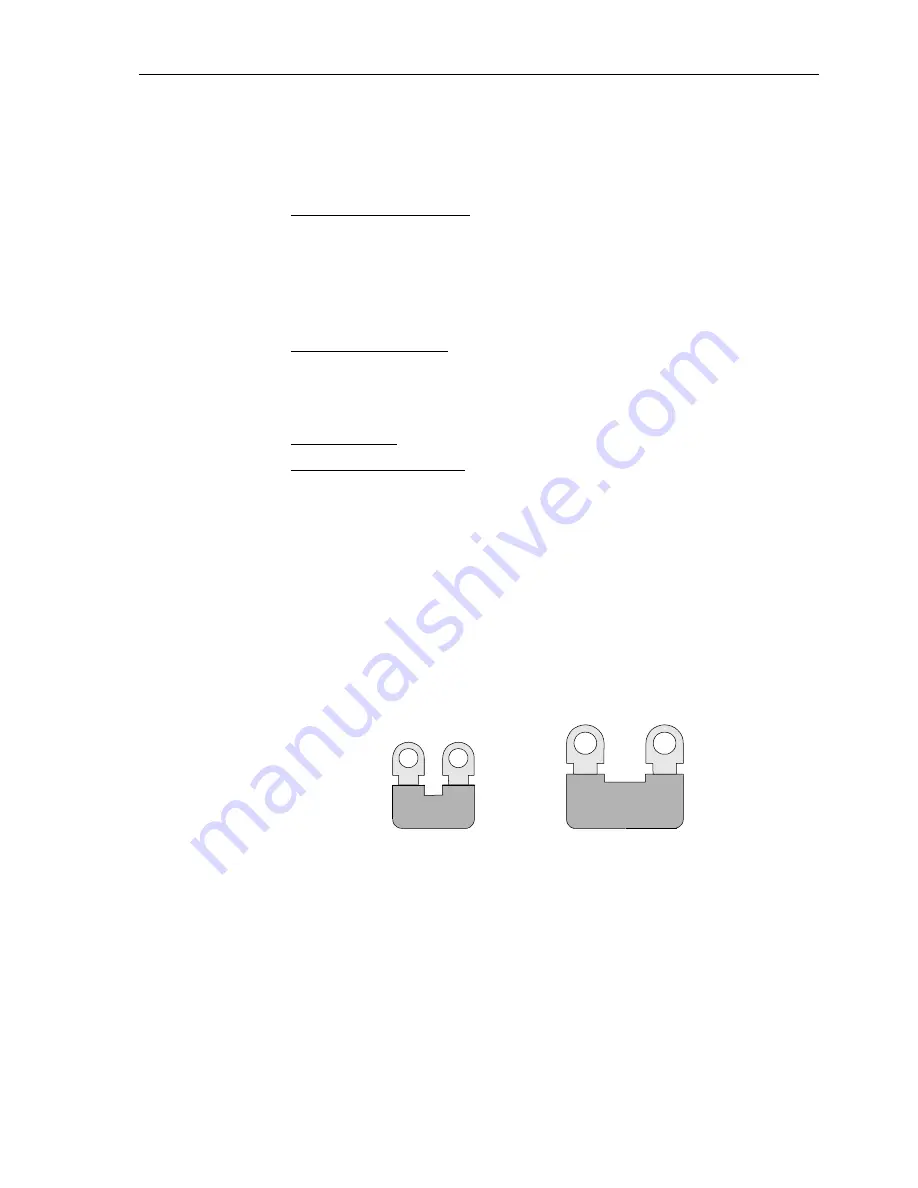

Short-Circuit Links

Short-circuit links are available for convenience in making terminal connections.

The short-circuit links can connect two neighbouring terminals located on the same

side of the terminal module. By connecting further links, neighbouring terminals can

be included in the short-circuit. On each terminal it is possible to connect two shot-

circuiting links, or one short-circuit link and one lug, or one individual conductor.

The links meet the safety requirements for protection against electric shock.

There are two types of links, one for voltage connections and one for current connec-

tions. The links are illustrated in Figure 2-12. Ordering information for the links is pro-

vided in Section A.1 in the Appendix.

Figure 2-12

Short-circuit links for voltage connections and current connections

Covering Caps

Terminal covering caps are available for the screw terminal modules, to increase the

protection of personnel against hazardous voltages (degree of protection against ac-

cess to dangerous parts) on the terminal modules. The degree of protection is in-

creased from the standard “back of the hand protection” (IP1x) to “finger protection”

(IP2x).

The terminal covering caps provide an enclosure which securely covers all voltage

carrying components. They are simply snapped onto the terminal module. It must be

Short-circuit links for

voltage connections

Short-circuit links for

current connections

Содержание siprotec 7SA6

Страница 2: ...Siemens Aktiengesellschaft Book No C53000 G1176 C156 2 ...

Страница 18: ...xviii 7SA6 Manual C53000 G1176 C156 2 ...

Страница 32: ...Introduction 1 14 7SA6 Manual C53000 G1176 C156 2 ...

Страница 82: ...Hardware and Connections 2 50 7SA6 Manual C53000 G1176 C156 2 ...

Страница 119: ...SIPROTEC 4 Devices 4 25 7SA6 Manual C53000 G1176 C156 2 Figure 4 20 CFC Logic example ...

Страница 190: ...Configuration 5 62 7SA6 Manual C53000 G1176 C156 2 ...

Страница 559: ...Control During Operation 7 45 7SA6 Manual C53000 G1176 C156 2 Figure 7 45 Circuit breaker trip test in DIGSI 4 ...

Страница 652: ...Installation and Commissioning 8 78 7SA6 Manual C53000 G1176 C156 2 ...

Страница 724: ...Technical Data 10 56 7SA6 Manual C53000 G1176 C156 ...

Страница 800: ...Appendix A 76 7SA6 Manual C53000 G1176 C156 2 ...

Страница 866: ...Appendix B 66 7SA6 Manual C53000 G1176 C156 2 ...