Periodic Maintenance

8-7

WARNING

8.4.5.

Ground Continuity

Perform the ground continuity test described below.

Do not perform this continuity test with the AC plug connected to a power receptacle.

Connect the Interconnect Cable to the C-Arm and verify continuity between the following:

From

To

Spec

Workstation

The right-top screw of WorkStation back cover

AC Power Plug Ground Pin

< 0.5

Ω

Any one of screws to fix Monitor

AC Power Plug Ground Pin

< 0.5

Ω

Mainframe

Any one of screws on the tube cover

AC Power Plug Ground Pin

< 0.5

Ω

Any one of screws to fix the Image Intensifier

AC Power Plug Ground Pin

< 0.5

Ω

Metal surface of central C-arm.

Comments: Close to the zero mark of orbital.

AC Power Plug Ground Pin

< 0.5

Ω

Metal surface of lock wrench of interconnector cable

AC Power Plug Ground Pin

< 0.5

Ω

If there is special ground continuity regulation for in used system, FE shall follow local

regulation and perform the test by Ground Continuity test equipment.

Below is the special regulation for Ground Continuity:

The resistance measured from the ground pin on the power cord to any accessible

conductive surface in the system (e.g., the chasis) shall not exceed 0.3 Ohm per European

norm EN 62353, specification.

The resistance measured from the ground pin on the power cord to any accessible

conductive surface in the system (e.g., the chasis) shall not exceed 0.2 ohms per IEC

60601-1 or equivalent.

8.4.6.

Facility Leakage Current Test Notification

The medical facility may require that the facility’s biomedical department or the 3

rd

service party to

perform current leakage test on the system before it is put into the service and during the periodic

maintenance. In that case, notify the service personnel of following warning:

Power off the system before and during any tests. Do not interrupt power to the system

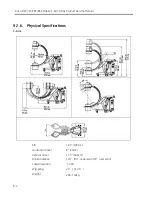

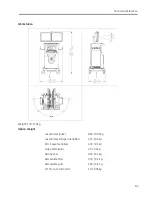

at any time while the system is booting or shutting down to avoid file system corruption.

WARNING

Содержание Brivo OEC 715

Страница 2: ......

Страница 19: ...Chapter1 Introduction and Safety...

Страница 41: ...Introduction and Safety 23 46 54 20 18 26...

Страница 55: ...Chapter2 System Overview...

Страница 137: ...Chapter3 Installation...

Страница 147: ...Installation 3 11 7 Put the ramp in position Release all bracket and move the workstation along the ramp off the pallet...

Страница 211: ...Installation 3 75 3 9 Reporting For U S Systems Complete and submit Form 2579 within 15 days of installation...

Страница 212: ...Chapter4 Calibration...

Страница 223: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 12 Mainframe Control Board TP7...

Страница 231: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 20 Mainframe Control Board TP17 POT4 J5 TP7 POT7 POT5...

Страница 275: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 64...

Страница 284: ...Chapter5 Software...

Страница 312: ...Software 5 29 4 Click Next 5 Click Install 6 Click Finish button to complete installation procedure...

Страница 326: ...Software 5 43 2 Click on install to continue 3 Click Next to continue...

Страница 335: ...Chapter6 Troubleshooting...

Страница 408: ...Chapter7 Replacement...

Страница 418: ...Replacement 7 11 166...

Страница 488: ...Chapter8 Periodic Maintenance...

Страница 502: ...Periodic Maintenance 8 15...

Страница 505: ...Chapter9 Technical Reference...

Страница 520: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 9 16 Lateral configuration 1 5m Lateral configuration 1m...

Страница 521: ...Technical Reference 9 17 Vertical configuration 1 5m Vertical configuration 1m...

Страница 526: ...11 Appendix System Schematics...