System Overview

2-63

Image Chain

Overview

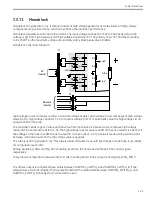

The following diagram is the image chain pipeline of Brivo715/785/865.

Collimator collimates the X-ray beam to the appropriate field size and user’s setting. The x-ray beam passes

through Grid to reduce scattered X-ray photons. Image Intensifier converts this X-ray into lights for each field size

selection, and sends the light to CCD Camera head. CCD Camera head captures the light image and sends the

digital video data by Gigabit LAN to Network card. Network card input digital video to CPU, and the CPU performs

real-time post-processing (Brightness, Contrast, Edge Enhance, Zoom, and Negate) to be sent to image display.

CPU also analyzes the digital video signal, and outputs a video level indicator (VLI) to MCB; higher VLI when the X-

ray dose is higher than desired, and lower VLI when the X-ray dose is lower than desired. With AutoTechnique

enabled, VLI will be processed by MCB S/W, and commands will be sent to X-ray Generator and GigE Camera to

change kVp/mA/gain depending on the VLI value. Finally the optimized image and exposure technique are

produced.

Collimator Control

Collimator:

The collimator is an electromechanical assembly designed to allow the operator to restrict the size and

shape of the X-ray beam. The unit has a lead iris and shutters and is mounted directly over the X-ray tube

beam aperture. There are 3 motions in collimator: iris open/close; shutter open/close; shutter rotation.

-

The diameter of the iris aperture

-

The gap spacing between the semi-transparent copper leaves

-

The rotational position/orientation of the copper leaves

Collimator specification:

-

Length

×

Width

×

Height: 180 mm

×

130 mm

×

95 mm

-

Weight: 1.65kg

-

8 leaves motorized iris collimator

-

2 blades motorized shutter

-

Shutter rotate angle: 360 degree

Collimator Control:

Overview

Collimator control subsystem is responsible for collimator motion control and status feedback. It consists of

Mother Board/MCB/CCB/collimator/cables between them and firmware in MCB.

X-ray Generation

X-ray Detection

Image Acquisition

Image Processing

Image Display

Grid

X-rays

Light

X-rays

Digital 12 bit

Gigabit Lan

Digital

8 bit

GigE

Camera

Network

card

I.I

IP

CPU/

display

Left 19"

color/mono

LCD

Digital

12 bit

JPI (715,785)

Dunlee (865)

Thales

JHI: 1M Camera

Bigtide

X-ray

Gen

VLI

(kV, mA)

OEC 40kHz

Exposure

Manage

Gain

Содержание Brivo OEC 715

Страница 2: ......

Страница 19: ...Chapter1 Introduction and Safety...

Страница 41: ...Introduction and Safety 23 46 54 20 18 26...

Страница 55: ...Chapter2 System Overview...

Страница 137: ...Chapter3 Installation...

Страница 147: ...Installation 3 11 7 Put the ramp in position Release all bracket and move the workstation along the ramp off the pallet...

Страница 211: ...Installation 3 75 3 9 Reporting For U S Systems Complete and submit Form 2579 within 15 days of installation...

Страница 212: ...Chapter4 Calibration...

Страница 223: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 12 Mainframe Control Board TP7...

Страница 231: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 20 Mainframe Control Board TP17 POT4 J5 TP7 POT7 POT5...

Страница 275: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 4 64...

Страница 284: ...Chapter5 Software...

Страница 312: ...Software 5 29 4 Click Next 5 Click Install 6 Click Finish button to complete installation procedure...

Страница 326: ...Software 5 43 2 Click on install to continue 3 Click Next to continue...

Страница 335: ...Chapter6 Troubleshooting...

Страница 408: ...Chapter7 Replacement...

Страница 418: ...Replacement 7 11 166...

Страница 488: ...Chapter8 Periodic Maintenance...

Страница 502: ...Periodic Maintenance 8 15...

Страница 505: ...Chapter9 Technical Reference...

Страница 520: ...Brivo OEC 715 785 865 Mobile C Arm X Ray Product Service Manual 9 16 Lateral configuration 1 5m Lateral configuration 1m...

Страница 521: ...Technical Reference 9 17 Vertical configuration 1 5m Vertical configuration 1m...

Страница 526: ...11 Appendix System Schematics...