Tension control parameter group 14

PARAMETER DESCRIPTION 305

5.15.7 Pre-drive control

Changing roll during operation can prevent large impact.

Parameter

Name

Default Setting Range

Content

14-41

P.645

Pre-drive speed gain

0.0%

-50.0%~50.0% Pre-drive speed gain

14-42

P.646

Pre-drive

torque

increase

0.0%

-50.0%~50.0% Pre-drive torque gain percentage

14-43

P.647

Pre-drive delay

0ms

0~65535ms

Pre-drive torque increase delay

Pre-drive control

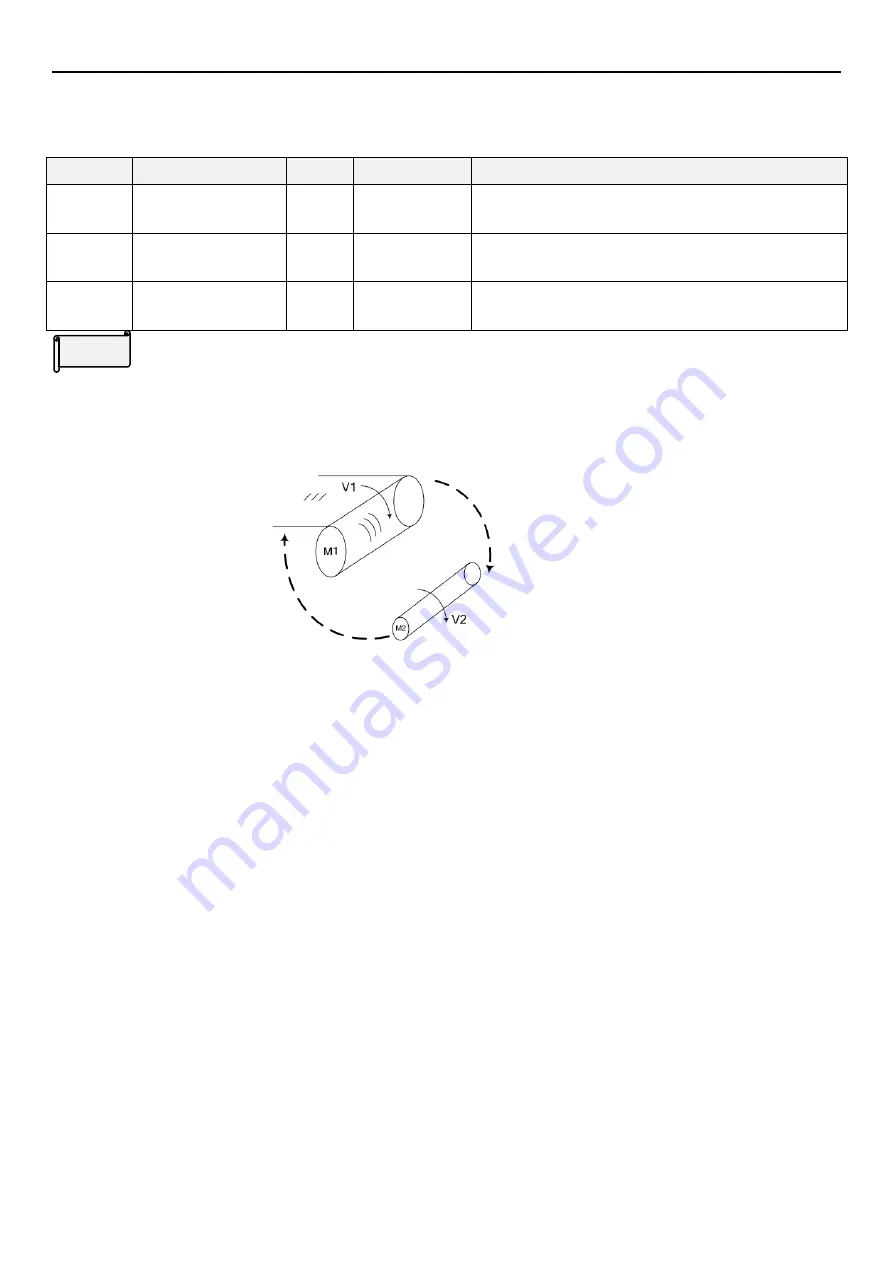

The schematic diagram of auto roll change is as follows,there are two inverters which controls upper roll and lower

roll change.

M1 is called"lower roll to be changed",M2 is called “upper roll to be changed" or "pre-drive roll"

To raise productivity, the winding shaft will generally be switched without turning off the machine. In order to

achieve smooth roll changing and avoid large impact, rotating the winding shaft before hand would be necessary.

The rotation linear speed and the material linear speed is the same.(V1≈V2).This function is called pre-drive.

Auto roll change control logic

When continuous work, the auto roll change logic is used to achieve a smooth changing process in order to raise

productivity. To achieve auto roll change, external controller is necessary. Motion B、C、D is only active when the

lower roll inverter operates in closed-loop vector control mode.

1.

Pre-drive process

When the upper roll inverter receives the pre-drive command, no matter how 14-00(P.600) is set, it will

operate according to the matching frequency calculated by the given linear speed and the initial winding

radius until the linear speed of the upper roll is consistent with the system linear speed. When the pre-drive

signal disappears, the control mode will be switched to tension control mode.

Setting