Installing the CH Hopper Cone

Section

Install the hopper cone section on the floor stand using the following steps.

IMPORTANT:

You will need to consider the location of the CH Hopper’s deliv-

ery air inlet in relation to the dryer installation location for proper setup.

IMPORTANT:

You will need to consider the location of the HTC heater outlet

in relation to the CH Hopper air inlet location for proper setup.

1

If any hoses, wires, etc. were attached to the floor stand and cone

section

(for shipping purposes), make sure they are positioned away

from the mating surfaces of the assemblies so they will not be damaged

during this procedure.

2

Using a forklift, hoist or crane, lift the cone section assembly above

the floor stand.

CAUTION:

To prevent accident and injury, lift the cone and hopper sections

onto the floor stand assembly using a forklift, hoist or crane.

3

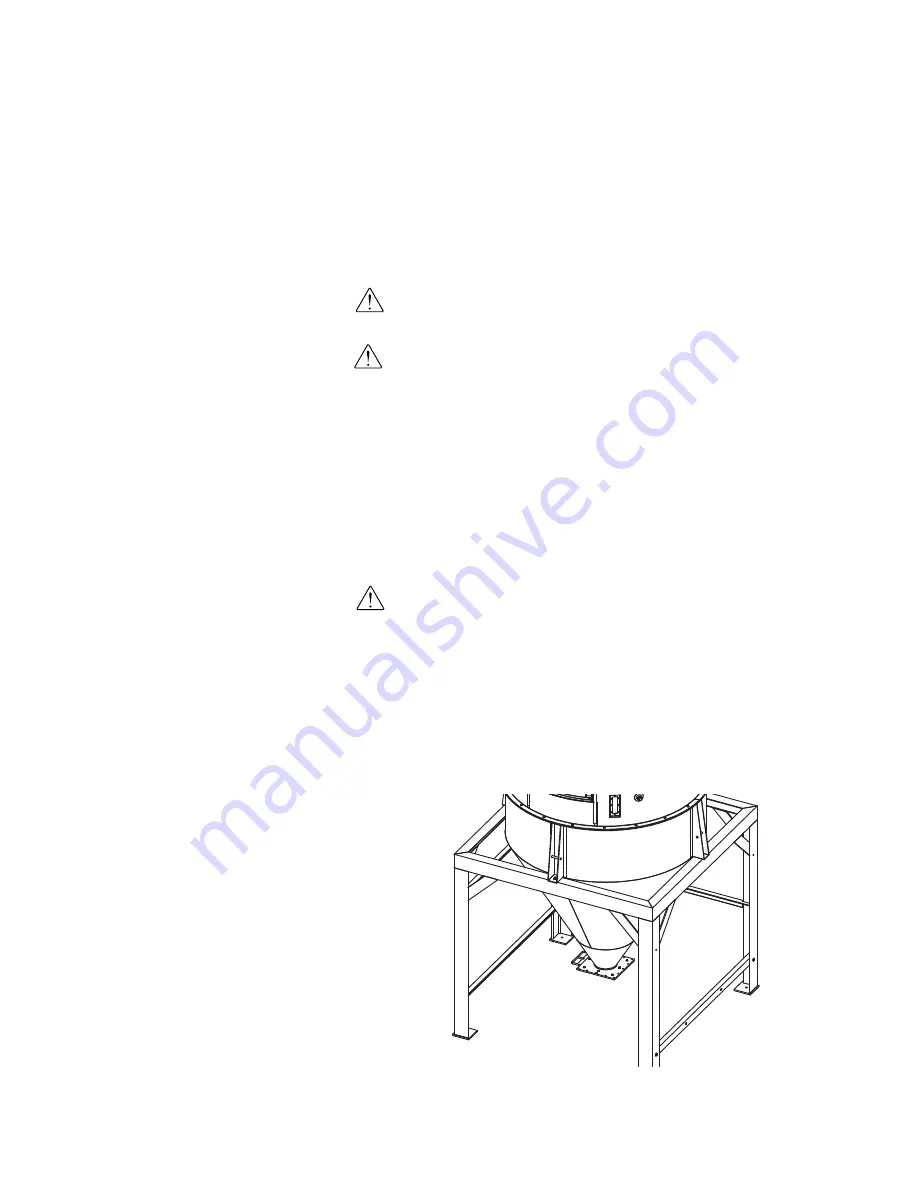

Set the cone section on the floor stand as shown.

Make sure the holes

in the cone section mounting lugs align with the holes in the top of the

floor stand assembly.

4

Secure the cone section to the floor stand assembly

using the supplied

hardware.

NOTE:

For EnergySmart Dryer

Systems supplied with "small"

hoppers, the floor stand and cone

section may be pre-assembled at

the factory. If your floor stand

and cone section are pre-assem-

bled and you have secured the

floor stand to the floor,

see

Installation section entitled,

Installing the CH Hopper Door,

Upper and Lid Sections.

✐

3-12

l I n s t a l l a t i o n - G e n e r a l

NOTE:

If using carbon steel hop-

pers, be sure to clean out the

hopper prior to use. Conair

applies a rust inhibitor that must

be removed several hours before

using the hopper.

✐

Summary of Contents for HTC 120

Page 10: ...viii l Table of Contents ...

Page 30: ...2 14 l Description ...

Page 35: ...Installation General Installation General l 3 5 3 I n s t a l l a t i o n ...

Page 65: ...Installation Hard Piping Kits Installation Piping Hoses l 3 35 3 I n s t a l l a t i o n ...

Page 80: ...3 50 l Installation Piping Hoses ...

Page 88: ...3 58 l Installation Piping Hoses ...

Page 92: ...3 62 l Installation Conveying Lines ...

Page 93: ...Installation Water Lines 3 I n s t a l l a t i o n Installation Water Lines l 3 63 ...

Page 124: ...3 94 l Installation Gas Piping and Exhaust Flue ...

Page 125: ...Installation Testing 3 I n s t a l l a t i o n Installation Testing l 3 95 ...

Page 250: ...4 108 l Operation ...

Page 286: ...5 36 l Maintenance ...