4-2

l O p e r a t i o n

The Energ ySmart Dr yer System

Control Panel

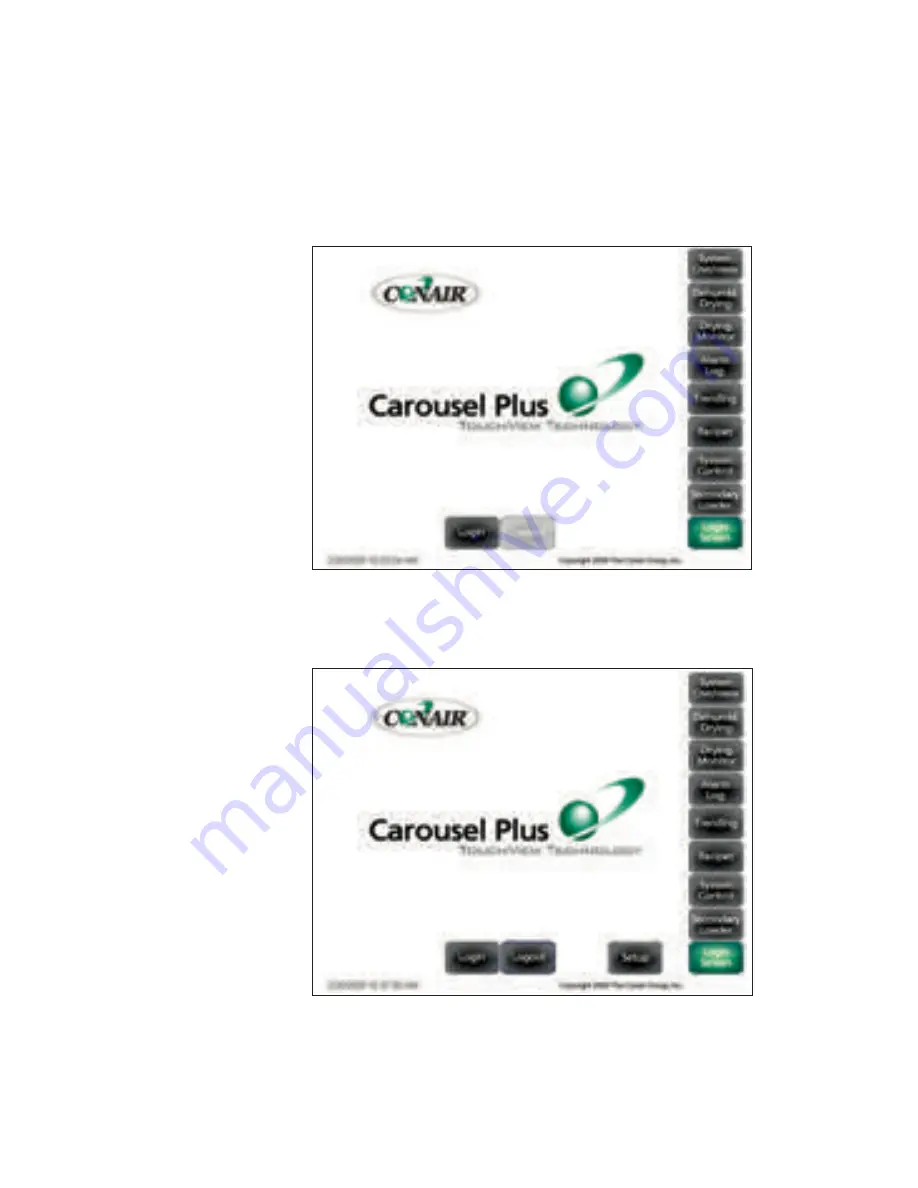

On power-up, the EnergySmart

®

Dryer control displays the initial system "Login"

screen (Screen 1A).

At start-up, the system security level is "Default". Once the operator enters the

user name and password, access is permitted to the "Login Setup" screen (Screen

1B). From this screen the user, depending on security access level, can access the

various system and setup screens for the entire EnergySmart Dryer system.

The following two sections provide flowcharts that detail the navigation between

the EnergySmart Dryer Control screens and provide a description of the function-

ality of each screen.

Summary of Contents for HTC 120

Page 10: ...viii l Table of Contents ...

Page 30: ...2 14 l Description ...

Page 35: ...Installation General Installation General l 3 5 3 I n s t a l l a t i o n ...

Page 65: ...Installation Hard Piping Kits Installation Piping Hoses l 3 35 3 I n s t a l l a t i o n ...

Page 80: ...3 50 l Installation Piping Hoses ...

Page 88: ...3 58 l Installation Piping Hoses ...

Page 92: ...3 62 l Installation Conveying Lines ...

Page 93: ...Installation Water Lines 3 I n s t a l l a t i o n Installation Water Lines l 3 63 ...

Page 124: ...3 94 l Installation Gas Piping and Exhaust Flue ...

Page 125: ...Installation Testing 3 I n s t a l l a t i o n Installation Testing l 3 95 ...

Page 250: ...4 108 l Operation ...

Page 286: ...5 36 l Maintenance ...