Page A-23

Deutsch Connector Assembly

DT Type

Wire Gauge

Range

Strip Length

(inches)

Contact Part

Number

0460-202-20141

20 AWG

.156-.218

0462-201-20141

20 AWG

.156-.218

0460-202-16141

16, 18 & 20 AWG

.250-.312

0462-201-16141

16, 18 & 20 AWG

.250-.312

0460-215-16141

14 AWG

.250-.312

0462-209-16141

14 AWG

.250-.312

0460-204-12141

12 & 14 AWG

.222-.284

0462-203-12141

12 & 14 AWG

.222-.284

0460-204-08141

8 & 10 AWG

.430-.492

0462-203-08141

8 & 10 AWG

.430-.492

0460-204-0490

6 AWG

.430-.492

0462-203-04141

6 AWG

.430-.492

1. Grasp crimped contact

approximately (25.2 mm) one

inch behind the contact barrel.

2. Hold connector with rear

grommet facing you.

3. Push contact straight into

connector grommet until a click

is felt. A slight tug will confirm

that contact is properly locked

in place.

4. Once all contacts are in place,

insert wedgelock with arrow pointing

toward exterior locking mechanism.

The wedgelock will snap into place.

Rectangular wedges are not oriented.

They may go in either way.

NOTE: The receptacle is shown –use the

same procedure for plug.

Step 1: Contact Removal

Step 4: Contact Insertion

Step 2: Wire Stripping

1. Remove wedgelock using

needlenose pliers or a hook

shaped wire. Pull wedge

straight out.

2. To remove the contacts,

gently pull wire backwards,

while at the same time

releasing the locking finger

by moving it away from the

contact with a screwdriver.

3. Hold the rear seal in

place, as removing the

contact may displace the

seal.

(800) 223-1236

Solid Contacts

Step 3: Contact Crimping

5. Insert wire into contact.

Contact must be centered

between indicators. Close

handles until crimp cycle is

completed.

6. Release handles and remove

crimped contact.

1. Strip insulation from wire.

(See Step 2).

2. Raise selector knob and

rotate until arrow is aligned with

wire size to be crimped.

3. Loosen locknut, turn adjust-

ing screw in until it stops.

4. Insert contact with barrel up.

Turn adjusting screw counter–

clockwise until contact is flush

with indentor cover. Tighten

locknut.

7. Inspect terminal to ensure

that all strands are in crimp

barrel.

NOTE:

Tool must be

readjusted for each type/size

of contact. Use HDT04-08 for

size 8 and 4 contacts.

Use Crimp Tool #HDT48-00

Содержание ClearCommand 9000 Series

Страница 1: ...ClearCommand 9000 Series Installation Operation and Troubleshooting Manual MM9000 I Rev C 2 5 08...

Страница 132: ......

Страница 133: ...APPENDIX A...

Страница 134: ......

Страница 139: ......

Страница 140: ...Page A 4...

Страница 143: ......

Страница 144: ...10...

Страница 148: ...Page A 18...

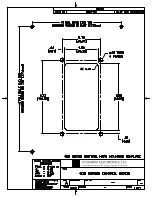

Страница 149: ...Page A 19 TEMPLATE...

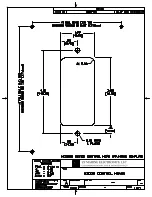

Страница 150: ...Page A 20...

Страница 152: ...Page A 22...

Страница 154: ...Page A 24...

Страница 156: ...Page A 26...

Страница 157: ...Page A 27 Drawing 11488D 1 Twin Screw Single APS Connection Alternate Remote Switch...

Страница 158: ...Page A 28...

Страница 159: ...Page A 29 Drawing 11488D 2 Twin Screw Dual APS Connections...

Страница 160: ...Page A 30...

Страница 161: ...Page A 31 Drawing 11488D 3 APS Notes Page...

Страница 162: ...Page A 32...

Страница 164: ...Page A 34...

Страница 166: ...Page A 36...

Страница 170: ...Page A 40...

Страница 172: ...Page A 42...

Страница 176: ...Page A 46...

Страница 178: ...Page C 48 ZF Mathers LLC 12125 Harbour Reach Drive Suite B Mukilteo WA 98275...

Страница 179: ...APPENDIX B...

Страница 180: ......

Страница 234: ...Appendix B 6...

Страница 238: ...Appendix B 10...

Страница 242: ...Appendix B 14...

Страница 247: ...Service Field Test Unit Reference Manual MM13927 Rev E 4 07...

Страница 248: ......

Страница 250: ...Page ii Table of Contents...

Страница 264: ...SERVICE FIELD TEST UNIT MM13927 RvD 10 03 Page 3 2...

Страница 265: ...APPENDIX C...

Страница 266: ......

Страница 267: ...Appendix C 1 Drawing 12284A 1 ClearCommand Diagram all options...

Страница 268: ...Appendix C 2...

Страница 269: ...Appendix C 3 Drawing 12284A 2 ClearCommand Circuit Board Connections...

Страница 270: ...Appendix C 4...

Страница 271: ...Appendix C 5 Drawing 12284A 3 ClearCommand Drawing Notes Page...

Страница 272: ...Appendix C 6...