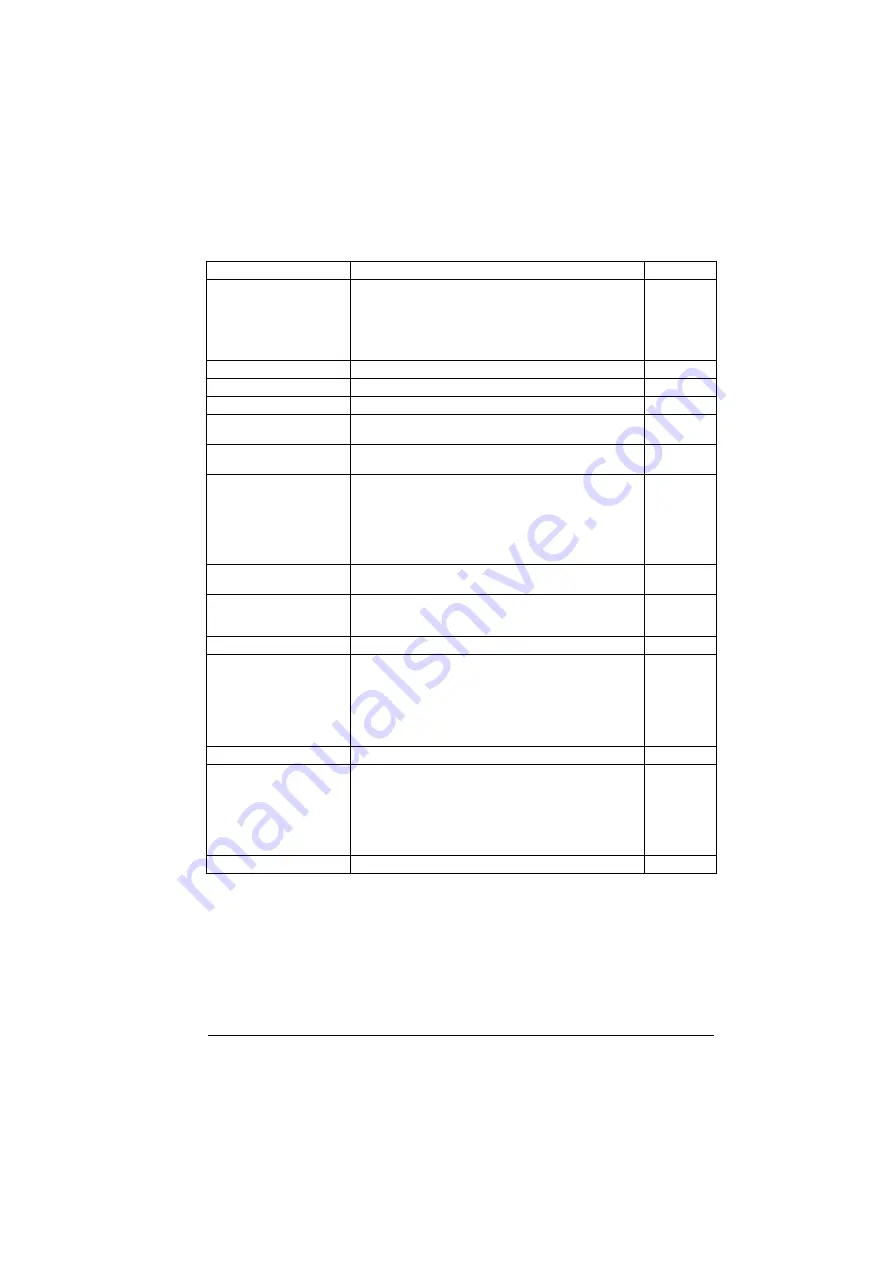

Parameters 313

Selects the source for quick brake chopper on/off control.

0 = Brake chopper IGBT pulses are cut off

1 = Normal brake chopper IGBT modulation allowed.

This parameter can be used to enable chopper operation only

when the supply is missing from a drive with a regenerative

supply unit.

Off

0.

0

On

1.

1

). -

Defines the thermal time constant for the brake resistor

thermal model.

0 s

0…10000 s

Brake resistor thermal time constant, ie the rated time to

achieve 63% temperature.

1 = 1 s

Defines the maximum continuous load of the brake resistor

that will eventually raise the resistor temperature to the

maximum allowed value (= continuous heat dissipation

capacity of the resistor in kW) but not above it. The value is

used in the resistor overload protection based on the thermal

model. See parameter

the

data sheet of the brake resistor used.

0.00 kW

0.00…

10000.00 kW

Maximum continuous load of the brake resistor.

1 = 1 kW

Defines the resistance value of the brake resistor. The value

is used for the brake resistor protection based on the thermal

model. See parameter

0.0 ohm

0.0…1000.0 ohm

Brake resistor resistance value.

1 = 1 ohm

Selects the fault limit for the brake resistor protection based

on the thermal model. See parameter

. When the limit is exceeded, the drive trips on fault

.

The value is given in percent of the temperature the resistor

reaches when loaded with the power defined by parameter

.

105%

0…150%

Brake resistor temperature fault limit.

1 = 1%

Selects the warning limit for the brake resistor protection

based on the thermal model. See parameter

. When the limit is exceeded, the drive

generates a

warning.

The value is given in percent of the temperature the resistor

reaches when loaded with the power defined by parameter

.

95%

0…150%

Brake resistor temperature warning limit.

1 = 1%

No.

Name/Value

Description

Def/FbEq16

Summary of Contents for ACS560

Page 1: ...ABB GENERAL PURPOSE DRIVES ACS560 standard control program Firmware manual...

Page 4: ...4...

Page 30: ...30 Start up control with I O and ID run...

Page 32: ...32 Using the control panel...

Page 100: ...100 Program features...

Page 153: ...Control macros 153...

Page 160: ...160...

Page 374: ...374 Parameters...

Page 408: ...408 Additional parameter data...

Page 466: ...466 Fieldbus control through the embedded fieldbus interface EFB...

Page 504: ...504 Control chain diagrams...

Page 508: ...508 Parameterization with drive composer...

Page 512: ...512 Parameterization with automation builder drive manager...