5-22

TI 71M01D06-01EN 3rd Edition: 2012.12.01

5.10.2

Ferrite Core 1

The ferrite core 1 is effective as a means of suppressing noise radiating from motor cables.

Mount it on a motor cable as close to the drive as possible.

The ferrite core 1 is not required if the drive is installed in a metal control panel/equipment and

does not affect devices located within the same equipment.

5.10.3

Ferrite Core 2

Ferrite core 2 is effective as a means of suppressing malfunction of the control power supply

caused by radiation emission.

Mount it on the control power supply cable as close to the drive control power supply terminal

as possible.

Ferrite core 2 is not required if the drive is installed in a metal control panel/device and there

is no noise source (bandwidth: 200 MHz to 300 MHz) that may cause malfunction of the

control power supply exists in a device within the same equipment.

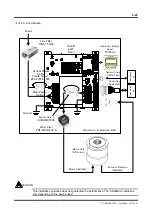

5.10.4

Motor Filter

A motor filter is effective as a means of suppressing the common mode noise generated by

an inverter.

Common mode noise is caused by high-frequency harmonic components in the current due

to switching in the inverter, which is conducted via the coupling capacity between motor cable

and motor coil and ground. A motor filter effectively suppresses high-frequency common

mode noise current.

If a CCD camera or measurement instrument is mounted on a platform where the length of a

motor cable exceeds 10m, in particular, the ground may become unstable due to the common

mode noise current, leading to a device malfunction.

Attach the filter to a motor cable as close to the drive as possible. Secure it to a metal plate in

the same way as for a line filter. However, be careful not to connect the input and output wires

of a filter. A motor filter is not required if the motor cables are short or there is no effect on

other devices located within the equipment.

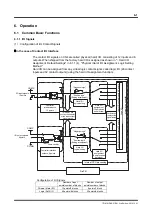

5.10.5

Shielding of Cables

The shielding of cables is effective as a means of suppressing motor malfunction due to

external noise and inverter noise, and in suppressing the influence on other devices resulting

from the inverter harmonic components and noise irradiated from the CPU clock.

The shielding of motor cables and encoder/resolver cables must be securely connected to

grounds on the drive and motor sides. Such shielding lowers the high-frequency impedance

to the ground between the motor and drive, and it suppresses the malfunctioning of the

encoder due to external noise and inverter noise.

For a controller cable, securely connect the shielding to the ground on both the drive and

controller sides. Such shielding lowers the impedance to the ground between the controller

and drive, and it suppresses the malfunction of pulse position command input and analog

velocity command.