13 - 32

Chapter 13 Control Sub Functions

(5) During simultaneous start, a stroke limit check is carried out for the current

values of every axis to be started. Every axis will not start if an error occurs,

even if it only occurs in one axis.

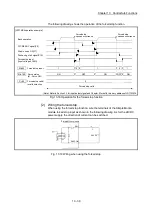

[5] Setting the software stroke limit function

To use the "software stroke limit function", set the required values in the

parameters shown in the following table, and write them to the Simple Motion

module.

The set details are validated at the rising edge (OFF

ON) of the PLC READY

signal [Y0].

Setting item

Setting

value

Setting details

Factory-set

initial value

Pr.12

Software stroke

limit upper limit

value

Set the upper limit value of the moveable range.

2147483647

Pr.13

Software stroke

limit lower limit

value

Set the lower limit value of the moveable range.

–2147483648

Pr.14

Software stroke

limit selection

Set whether to use the "

Md.20

Current feed value

" or

"

Md.21

Machine feed value

" as the "current value".

0: Current feed

value

Pr.15

Software stroke

limit valid/invalid

setting

0:Valid

Set whether the software stroke limit is validated or

invalidated during manual control (JOG operation,

Inching operation, manual pulse generator operation).

0: valid

:

Refer to Section 5.2 "List of parameters" for setting details.

[6] Invalidating the software stroke limit

To invalidate the software stroke limit, set the following parameters as shown,

and write them to the Simple Motion module. (Set the value within the setting

range.)

Pr.12

Software stroke limit

upper limit value

=

Pr.13

Software stroke limit

lower limit value

(To invalidate only the manual operation, set "1: software stroke limit invalid" in

the "

Pr.15

Software stroke limit valid/invalid setting

".)

The set details are validated at the rising edge (OFF

ON) of the PLC READY

signal [Y0].

When the unit is "degree", the software stroke limit check is not performed during

speed control (including speed control in speed-position switching control or

position-speed switching control) or during manual control, independently of the

values set in

Pr.12

,

Pr.13

and

Pr.15

.

REMARK

Parameters are set for each axis.

It is recommended that the parameters be set whenever possible with GX Works2.

Execution by sequence program uses many sequence programs and devices. The

execution becomes complicated, and the scan times will increase.

Summary of Contents for MELSEC-L Series

Page 2: ......

Page 30: ...MEMO ...

Page 70: ...2 10 Chapter 2 System Configuration MEMO ...

Page 83: ...3 13 Chapter 3 Specifications and Functions MEMO ...

Page 103: ...3 33 Chapter 3 Specifications and Functions MEMO ...

Page 107: ...3 37 Chapter 3 Specifications and Functions MEMO ...

Page 111: ...3 41 Chapter 3 Specifications and Functions MEMO ...

Page 115: ...3 45 Chapter 3 Specifications and Functions MEMO ...

Page 140: ...4 22 Chapter 4 Installation Wiring and Maintenance of the Product MEMO ...

Page 253: ...5 113 Chapter 5 Data Used for Positioning Control MEMO ...

Page 342: ...5 202 Chapter 5 Data Used for Positioning Control MEMO ...

Page 438: ...7 20 Chapter 7 Memory Configuration and Data Process MEMO ...

Page 440: ...MEMO ...

Page 485: ...9 25 Chapter 9 Major Positioning Control MEMO ...

Page 594: ...9 134 Chapter 9 Major Positioning Control MEMO ...

Page 624: ...10 30 Chapter 10 High Level Positioning Control MEMO ...

Page 656: ...11 32 Chapter 11 Manual Control MEMO ...

Page 690: ...12 34 Chapter 12 Expansion Control MEMO ...

Page 798: ...13 108 Chapter 13 Control Sub Functions MEMO ...

Page 866: ...14 68 Chapter 14 Common Functions MEMO ...

Page 884: ...15 18 Chapter 15 Dedicated Instructions MEMO ...

Page 899: ...16 15 Chapter 16 Troubleshooting MEMO ...

Page 1036: ...Appendix 88 Appendices MEMO ...

Page 1039: ......