4 - 11

Chapter 4 Installation, Wiring and Maintenance of the Product

[1] Precautions for wiring

(1) Use separate cables for connecting to the Simple Motion module and for the

power cable that create surge and inductance.

(2) The cable for connecting the Simple Motion module can be placed in the

duct or secured in place by clamps. If the cable is not placed in the duct or

secured by clamps, unevenness or movement of the cable or careless

pulling on it could result in damage to the unit or cable or defective cable

connections could cause mis-operation of the unit.

(3) If a duct is being used, separate the cables to connect the Simple Motion

module from the power line duct, or use metal piping.

Ground the pipes securely after metal piping.

(4) Use the twisted pair shielded cable (wire size AWG30 to AWG24 (0.05 to

0.2 mm

2

)). The shielded must be grounded in the cable connector shell.

(5) Use separate shielded cables of the forced stop input signal (EMI,

EMI.COM), external command signal/switching signal (DI1, DI2, DI3, DI4,

COM), and manual pulse generator/incremental synchronous encoder input

signal (HAH, HAL, HBH, HBL, HA, HB, 5V, SG) for connecting to the Simple

Motion module. They can cause electrical interference, surges and

inductance that can lead to mis-operation.

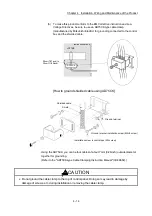

[Wiring example of shielded cable]

The following shows a wiring example for noise reduction in the case when the

connector (LD77MHIOCON) is used.

To the Simple Motion module

Connector

(LD77MHIOCON)

The shield must be grounded in the cable connector shell.

For manual pulse generator

/Incremental synchronous encoder input signal

For forced stop input signal

/External command signal/Switching signal

Shielded cable

Summary of Contents for MELSEC-L Series

Page 2: ......

Page 30: ...MEMO ...

Page 70: ...2 10 Chapter 2 System Configuration MEMO ...

Page 83: ...3 13 Chapter 3 Specifications and Functions MEMO ...

Page 103: ...3 33 Chapter 3 Specifications and Functions MEMO ...

Page 107: ...3 37 Chapter 3 Specifications and Functions MEMO ...

Page 111: ...3 41 Chapter 3 Specifications and Functions MEMO ...

Page 115: ...3 45 Chapter 3 Specifications and Functions MEMO ...

Page 140: ...4 22 Chapter 4 Installation Wiring and Maintenance of the Product MEMO ...

Page 253: ...5 113 Chapter 5 Data Used for Positioning Control MEMO ...

Page 342: ...5 202 Chapter 5 Data Used for Positioning Control MEMO ...

Page 438: ...7 20 Chapter 7 Memory Configuration and Data Process MEMO ...

Page 440: ...MEMO ...

Page 485: ...9 25 Chapter 9 Major Positioning Control MEMO ...

Page 594: ...9 134 Chapter 9 Major Positioning Control MEMO ...

Page 624: ...10 30 Chapter 10 High Level Positioning Control MEMO ...

Page 656: ...11 32 Chapter 11 Manual Control MEMO ...

Page 690: ...12 34 Chapter 12 Expansion Control MEMO ...

Page 798: ...13 108 Chapter 13 Control Sub Functions MEMO ...

Page 866: ...14 68 Chapter 14 Common Functions MEMO ...

Page 884: ...15 18 Chapter 15 Dedicated Instructions MEMO ...

Page 899: ...16 15 Chapter 16 Troubleshooting MEMO ...

Page 1036: ...Appendix 88 Appendices MEMO ...

Page 1039: ......