4 - 19

Chapter 4 Installation, Wiring and Maintenance of the Product

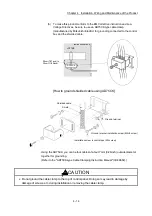

[4] Example of measure against noise for compliance with the EMC

directive.

PLC CPU LD77MS

SSCNET cable

: AD75CK cable clamp

: Ferrite core (NEC TOKIN Corporation)

AC power

supply

NF

24VDC

power supply

Power

supply

4)

4)

2)

2)

2)

2)

1)

1)

7)

6)

5)

5)

7)

1)

3)

3)

1) Install a ferrite core. (Approx. 2 turn)

2) Ground the cables at a position 20 to 30cm (7.87 to 11.82inch) away from the module, or at a position 5 to 10cm (1.97 to

3.94inch) away from the exit/entrance of the control panel with the cable clamp, etc.

3) Wire the power supply cable as short as possible using the twisted cable (2mm

2

or more).

4) Use the shielded twisted cable (cable length: 30m (98.43ft.) or less) for each I/O signal cable.

5) Wire the cable connected to secondary side of 24VDC power supply module as short as possible using the shielded

twisted cable.

6) Wire the cable connected to FG terminal of LD77MS as short as possible using the cable of 0.517 to 1.31mm

2

, and

ground to the control panel.

7) Wire the power supply and 24VDC power supply as short as possible using the cable of approx. 2mm

2

, and ground to

the control panel.

Control panel: EC-SCF25-78 (Nitto Kogyo Corporation)

(1)

Refer to this chapter or "EMC and Low Voltage Directives" of "MELSEC-L CPU

Module User's Manual (Hardware Design, Maintenance and Inspection)" for basic

wire. We examined LD77MS by the above example.

(2)

In wiring inside the panel, the power line connected to the power or servo amplifier

and the communication cable such as an expansion cable or a network cable

must not be mixed. In the duct, leave 10cm (3.94inch) or more between the power

line and the communication cable, and separate using a separator (made of

metal), etc. It is required in the same control panel as well.

Mixing the power line and communication cable may cause increase of noise or

malfunction due to noise influence.

Summary of Contents for MELSEC-L Series

Page 2: ......

Page 30: ...MEMO ...

Page 70: ...2 10 Chapter 2 System Configuration MEMO ...

Page 83: ...3 13 Chapter 3 Specifications and Functions MEMO ...

Page 103: ...3 33 Chapter 3 Specifications and Functions MEMO ...

Page 107: ...3 37 Chapter 3 Specifications and Functions MEMO ...

Page 111: ...3 41 Chapter 3 Specifications and Functions MEMO ...

Page 115: ...3 45 Chapter 3 Specifications and Functions MEMO ...

Page 140: ...4 22 Chapter 4 Installation Wiring and Maintenance of the Product MEMO ...

Page 253: ...5 113 Chapter 5 Data Used for Positioning Control MEMO ...

Page 342: ...5 202 Chapter 5 Data Used for Positioning Control MEMO ...

Page 438: ...7 20 Chapter 7 Memory Configuration and Data Process MEMO ...

Page 440: ...MEMO ...

Page 485: ...9 25 Chapter 9 Major Positioning Control MEMO ...

Page 594: ...9 134 Chapter 9 Major Positioning Control MEMO ...

Page 624: ...10 30 Chapter 10 High Level Positioning Control MEMO ...

Page 656: ...11 32 Chapter 11 Manual Control MEMO ...

Page 690: ...12 34 Chapter 12 Expansion Control MEMO ...

Page 798: ...13 108 Chapter 13 Control Sub Functions MEMO ...

Page 866: ...14 68 Chapter 14 Common Functions MEMO ...

Page 884: ...15 18 Chapter 15 Dedicated Instructions MEMO ...

Page 899: ...16 15 Chapter 16 Troubleshooting MEMO ...

Page 1036: ...Appendix 88 Appendices MEMO ...

Page 1039: ......