9 - 52

Chapter 9 Major Positioning Control

9.2.7 2-axis fixed-feed control (interpolation)

In "2-axis fixed-feed control" ("

Da.2

Control method

" = fixed-feed 2), two motors are

used to carry out fixed-feed control in a linear path while carrying out interpolation for

the axis directions set in each axis.

In fixed-feed control, any remainder of below control accuracy is rounded down to

convert the movement amount designated in the positioning data into the command

value to servo amplifier.

(Refer to Section 9.1.6 "Interpolation control" for details on interpolation control.)

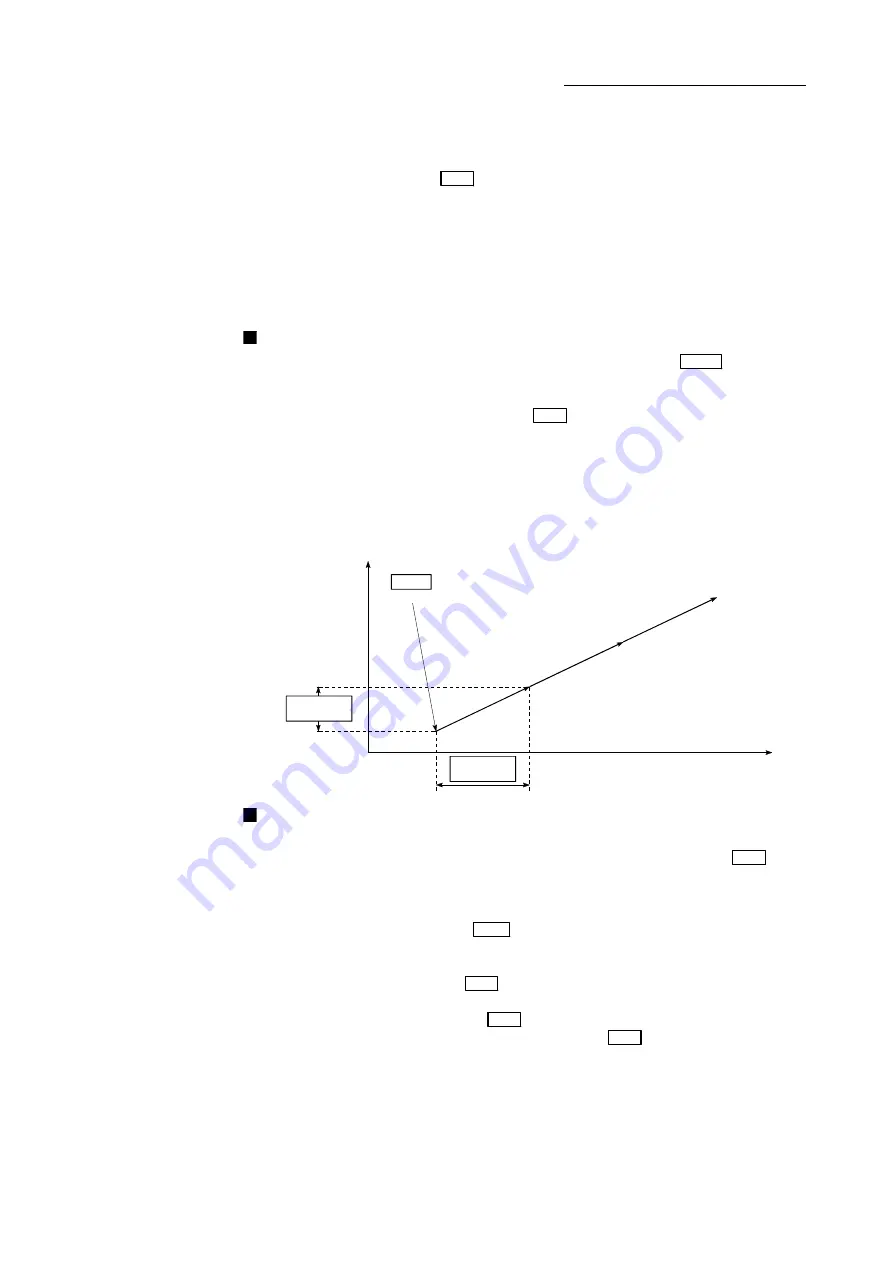

Operation chart

In incremental system 2-axis fixed-feed control, the addresses (

Md.20

Current feed

value

) of the current stop position (start addresses) of both axes are set to "0".

Linear interpolation positioning is then carried out from that position to a position at

the end of the movement amount set in "

Da.6

Positioning address/movement amount

".

The movement direction is determined by the sign of the movement amount.

• Positive movement amount .............. Positioning control to forward direction

(Address increase direction)

• Negative movement amount ............. Positioning control to reverse direction

(Address decrease direction)

" Md. 20 Current feed value" of each axis

is set to "0" at the positioning start

(0,0)

(0,0)

(0,0)

X axis

Y axis

Designated

movement

amount

Designated

movement

amount

Restrictions

(1) The error "Continuous path control not possible" (error code: 516) will occur

and the operation cannot start if "continuous path control" is set in "

Da.1

Operation pattern

". ("Continuous path control" cannot be set in fixed-feed

control.)

(2) If the movement amount of each axis exceeds "1073741824 (=2

30

)" when "0:

Composite speed" is set in "

Pr.20

Interpolation speed designation method

", the

error "Outside linear movement amount range" (error code: 504) occurs at a

positioning start and positioning cannot be started. (The maximum movement

amount that can be set in "

Da.6

Positioning address/movement amount

" is

"1073741824 (= 2

30

)".

(3) "Fixed-feed" cannot be set in "

Da.2

Control method

" in the positioning data

when "continuous path control" has been set in "

Da.1

Operation pattern

" of the

immediately prior positioning data. (For example, if the operation pattern of

positioning data No. 1 is "continuous path control", fixed-feed control cannot

be set in positioning data No. 2.) The error "Continuous path control not

possible" (error code: 516) will occur and the machine will carry out a

deceleration stop if this type of setting is carried out.

Summary of Contents for MELSEC-L Series

Page 2: ......

Page 30: ...MEMO ...

Page 70: ...2 10 Chapter 2 System Configuration MEMO ...

Page 83: ...3 13 Chapter 3 Specifications and Functions MEMO ...

Page 103: ...3 33 Chapter 3 Specifications and Functions MEMO ...

Page 107: ...3 37 Chapter 3 Specifications and Functions MEMO ...

Page 111: ...3 41 Chapter 3 Specifications and Functions MEMO ...

Page 115: ...3 45 Chapter 3 Specifications and Functions MEMO ...

Page 140: ...4 22 Chapter 4 Installation Wiring and Maintenance of the Product MEMO ...

Page 253: ...5 113 Chapter 5 Data Used for Positioning Control MEMO ...

Page 342: ...5 202 Chapter 5 Data Used for Positioning Control MEMO ...

Page 438: ...7 20 Chapter 7 Memory Configuration and Data Process MEMO ...

Page 440: ...MEMO ...

Page 485: ...9 25 Chapter 9 Major Positioning Control MEMO ...

Page 594: ...9 134 Chapter 9 Major Positioning Control MEMO ...

Page 624: ...10 30 Chapter 10 High Level Positioning Control MEMO ...

Page 656: ...11 32 Chapter 11 Manual Control MEMO ...

Page 690: ...12 34 Chapter 12 Expansion Control MEMO ...

Page 798: ...13 108 Chapter 13 Control Sub Functions MEMO ...

Page 866: ...14 68 Chapter 14 Common Functions MEMO ...

Page 884: ...15 18 Chapter 15 Dedicated Instructions MEMO ...

Page 899: ...16 15 Chapter 16 Troubleshooting MEMO ...

Page 1036: ...Appendix 88 Appendices MEMO ...

Page 1039: ......