Optics Alignment (Required for Periodic Inspection or Installing X-Ray Tube)

MiniFlex 600: Benchtop X-ray Diffractometer

55

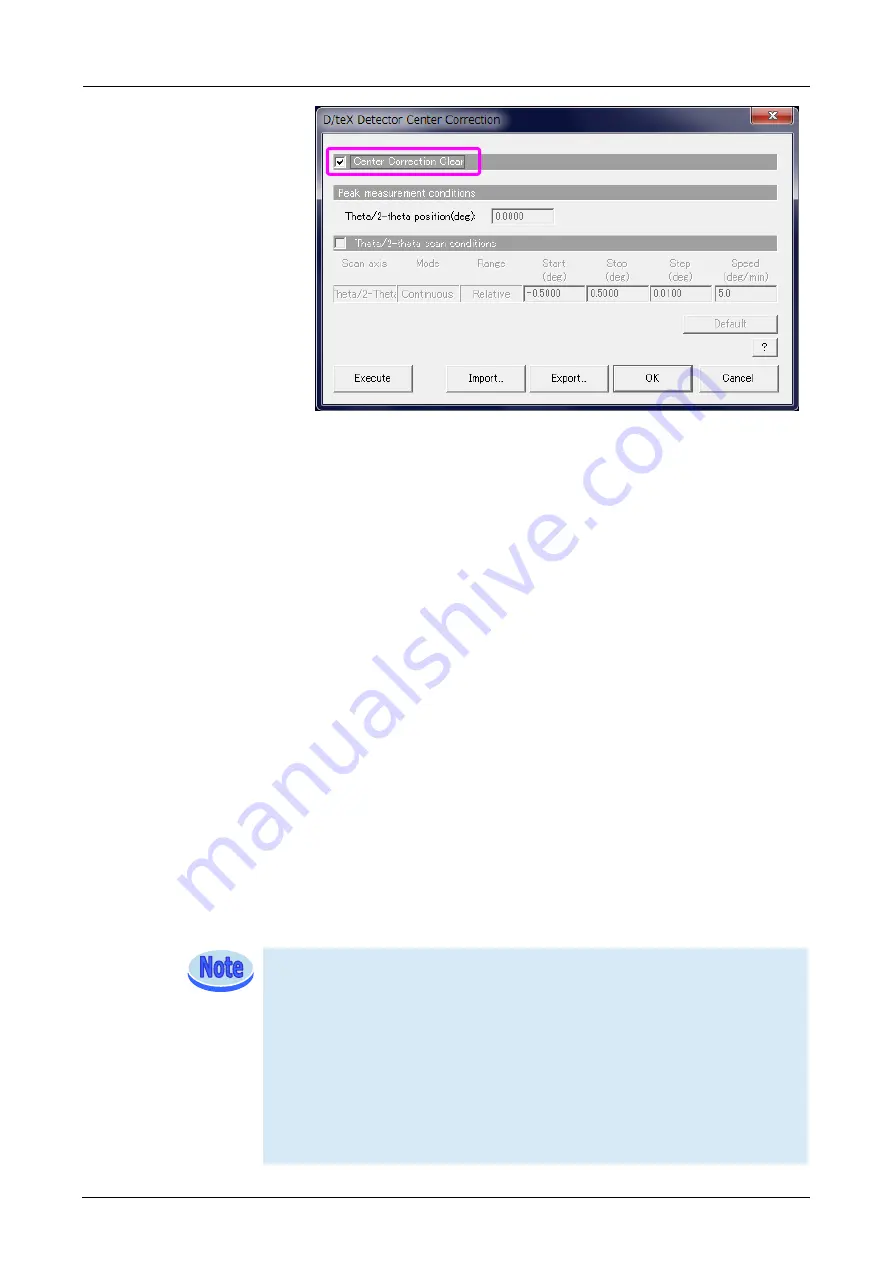

Fig. 6.2.35 D/teX center position correction window

6

Adjust the X-ray tube in vertical direction to position the direct beam

at an angle of 2θ/θ = 0º.

①

Select

Control

-

Manual Control

.

②

MiniFlex 600 measures direct beam under the following slit

conditions.

③

If the intensity of the direct beam is not within the range of 2,000 to

100,000cps, adjust the intensity by changing the number of absorbers

or the tube voltage output (see Fig. 6.2.10)

DS=1.25°, SS=absorber (Cu 0.3 mm x 1), RS=0.3mm

*The 1.25° slit is inserted into DS, but the slit width becomes 0.1 mm

at 2θ/θ

=

0° due to the variable DS.

*If the intensity is too strong, counting loss (dead-time) occurs and the

correct peak shape (see Fig. 6.2.37) cannot be obtained. When there

are concerns that counting loss (such as the top peak becoming flat,

or being separated into two peaks due to decrease of peak intensity)

may occur, add an absorber or change the tube voltage output. For

example, if it is too strong with 30 kV -10 mA, decrease to 26 kV

-10 mA.

・

Manual Control

is used for the measurement of direct beam position.

Turning X-rays on and off must be done manually in

Manual Control

.

・

Specification A

(including Japan):

X-ray generation is turned OFF when the door button is pressed to open the

door. After adjustment is completed, close the door and set

X-Ray ON

in the

XG Control

window to set the X-ray output again.

Specification B

:

The door can be opened while X-Ray is maintained ON (The X-ray shutter is

closed).