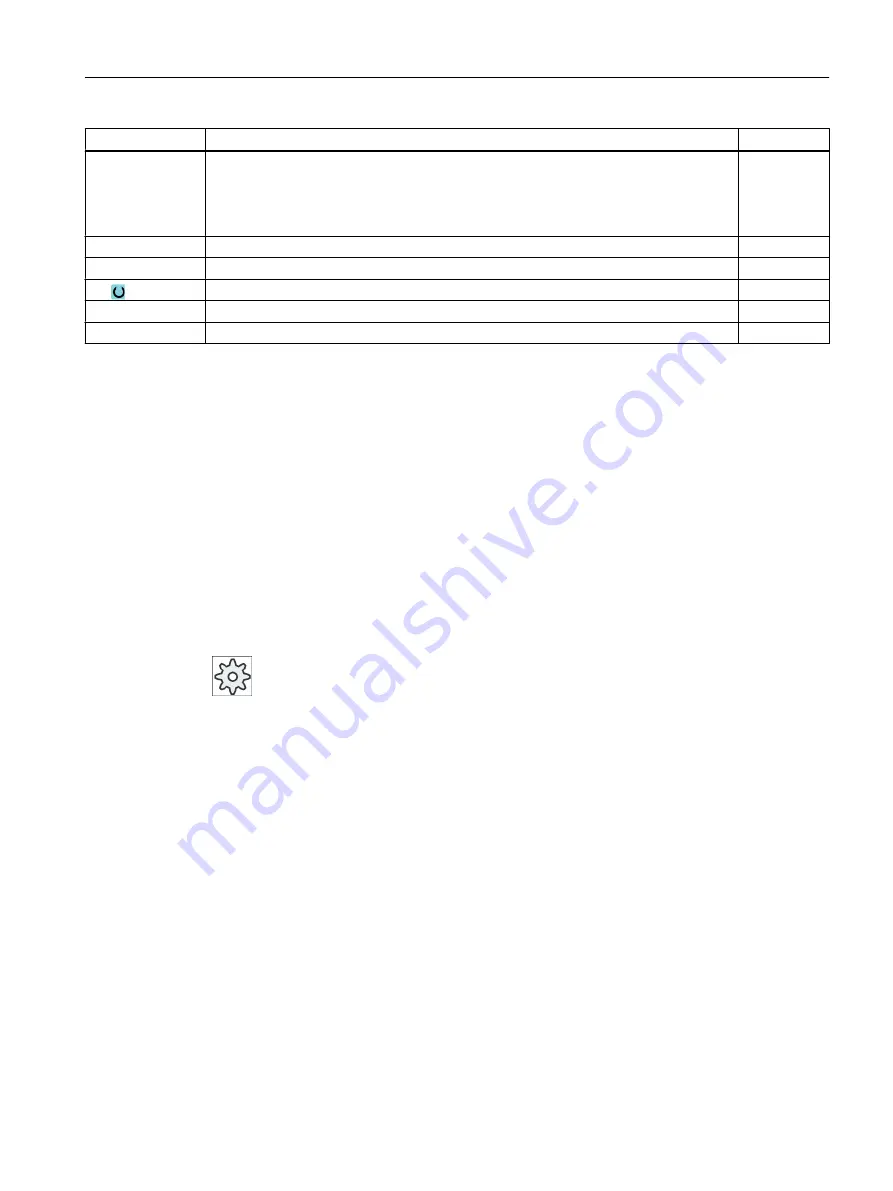

Parameter

Description

Unit

X0

Y0

Z0

The positions refer to the reference point:

Reference point X – (for single position only)

Reference point Y – (for single position only)

Reference point Z

mm

mm

mm

L

Elongated hole length

mm

α0

Angle of rotation

Degrees

Z1

Elongated hole depth (abs) or depth in relation to Z0 (inc)

mm

DZ

Maximum depth infeed

mm

FZ

Depth infeed rate

*

* Unit of feedrate as programmed before the cycle call

10.2.11

Thread milling (CYCLE70)

Function

Using a thread cutter, internal or external threads can be machined with the same pitch.

Threads can be machined as right-hand or left-hand threads and from top to bottom or vice

versa.

For metric threads (thread pitch P in mm/rev), the cycle assigns a value (calculated on the

basis of the thread pitch) to the thread depth H1 parameter. You can change this value. The

default selection must be activated via a machine data code.

Machine manufacturer

Please refer to the machine manufacturer's specifications.

The entered feedrate acts on the workpiece contour, i.e. it refers to the thread diameter.

However the feedrate of the cutter center point is displayed. That is why a smaller value is

displayed for internal threads and a larger value is displayed for external threads than was

entered.

Approach/retraction when milling internal threads

1. Positioning on retraction plane with rapid traverse.

2. Approach of starting point of the approach circle in the current plane with rapid traverse.

3. Infeed to a starting point in the tool axis calculated internally in the controller with rapid

traverse.

4. Approach motion to thread diameter on an approach circle calculated internally in the

controller with the programmed feedrate, taking into account the finishing allowance and

maximum plane infeed.

Programming technological functions (cycles)

10.2 Milling

Milling

Operating Manual, 08/2018, 6FC5398-7CP41-0BA0

471