65

Disassembly/Inspection and Service

17 690 15 Rev. --

KohlerEngines.com

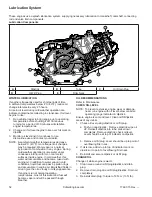

Remove Oil Fill Tube

Details

A

B

C

A

Oil Fill Tube

B

Oil Fill Tube Bracket

C

Bracket Screw

NOTE: Unless oil fi ll tube is damaged, disassembly from

closure plate is unnecessary.

1. Remove bracket screw and oil fi ll tube bracket.

2. If necessary, remove tube from closure plate. If not,

allow oil fi ll tube to remain in closure plate. Tube will

be removed with closure plate as an assembly.

Remove Closure Plate

NOTE: Do not pry on gasket surface of crankcase or

closure plate, as this can cause damage and

leakage.

1. Remove screws securing closure plate to crankcase.

2. Remove closure plate, gasket, and dowel pins (if

required) from crankcase.

3. Remove closure plate and oil fi ll tube as an

assembly.

4. Remove shims from crankshaft.

Inspection

Inspect main bearing surface for wear or damage (refer

to Specifi cations). Replace closure plate if required.

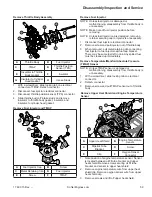

Remove Balance Shaft

Remove balance shaft (with wave spring) by pulling it

straight out of crankcase.

Remove Camshaft and Valve Tappets

1. Remove camshaft by pulling it straight out of

crankcase.

2. Remove valve tappets by pulling them straight out of

crankcase. Mark their positions.

Automatic Compression Release (ACR)

ACR Operation Details

B

C

E

D

A

A

Camshaft

B

Exhaust Cam Lobe

C

Decompression

Weight

D

Return Spring

E

Arm

ACR mechanism consists of a spring-loaded arm and

sliding pin mounted to camshaft. When engine is rotating

at low cranking speeds, arm holds pin so it protrudes

above heel of exhaust cam. This holds exhaust valve off

of its seat during fi rst part of compression stroke.

After engine speed increases centrifugal force causes

spring-loaded arm to move outward causing pin to

retract. When in this position pin has no eff ect on

exhaust valve and engine operates at full compression

and power.

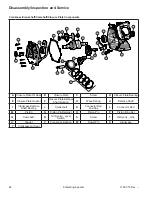

Benefi ts

As a result of reduced compression at cranking speeds,

several important benefi ts are obtained:

1. Electric start models can use a smaller starter and

battery more practical for application.

2. ACR eliminates need for a spark retard/advance

mechanism. ACR eliminates this kickback making

manual starting safer.

3. Engines with ACR start much faster in cold weather

than engines without ACR.

4. Engines with ACR can be started with worn or fouled

spark plug. Engines without ACR are more diffi cult to

start with those same spark plug.

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......