33

17 690 15 Rev. --

KohlerEngines.com

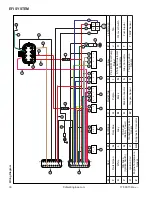

EFI SYSTEM

Oxygen Sensor (O2)

Detail

Pin D

Pin C

Pin B

Pin A

A

B

Pin A

Purple Wire,

Pin B

White Wire,

Heater -

Pin C

Grey Wire, Sensor

Output

Pin D

Black Wire, Sensor

Ground

A

14 mm or 9/16 in.

Wrench Size

B

12 mm x 1.25

Thread Size

Installation Torque 18 N·m (159 in. lb.)

Cutaway Oxygen Sensor (O2) Components

A

B

C

D

E

F

G

A

Protection Shield

B

Planar Element

and Heater

C

Lower Insulator

D

Stainless Steel

Housing

E

Upper Insulator

F

Terminal Connection

to Element

G

High Temp

Water Seal

Temperature must be controlled very accurately and gas

constituents measured to a high degree of accuracy for

absolute sensor measurements. This requires laboratory

equipment to determine a good or bad sensor in fi eld.

Furthermore, as with most devices, intermittent problems

are diffi cult to diagnose. Still, with a good understanding

of system and sensor, it is possible to diagnose many

sensor problems in fi eld.

Using diagnostic software connected to ECU is a useful

technique for observing sensor performance. However,

user must understand that such software reads a signal

generated by ECU. If there is an ECU or wiring problem,

readings could be misinterpreted as a sensor problem.

Digital nature of signal to software means that it is not

reading continuous output of sensor. A voltmeter can

also be used as an eff ective tool in diagnosing sensors.

It is advisable to use an electronic meter such as a

digital voltmeter. Simple mechanical meters may place

a heavy electrical load on sensor and cause inaccurate

readings. Since resistance of sensor is highest at

low temperatures, such meters will cause largest

inaccuracies when sensor is in a cool exhaust.

Visual Inspection

Sensor Wire Detail

A

A

Keep a minimum of 25 mm (1.0 in.) radius at

grommet.

NOTE: Always route harness away from hot exhaust

and away from moving parts.

NOTE:

Do not attempt to clean sensor.

Replace as

needed.

1. Look for a damaged or disconnected sensor-to-

engine harness connection.

2. Look for damage to sensor lead wire or associated

engine wiring due to cutting, chaffi ng or melting on a

hot surface.

3. Disconnect sensor connector and look for corrosion

in connector.

4. Try reconnecting sensor and observe if problem has

cleared.

5. Correct any problems found during visual check.

6. Inspect for any exhaust system leaks upstream or

downstream of oxygen sensor. Confi rm oxygen

sensor is secured to 18 N·m (159 in. lb.).

All leaks must be repaired and an ECU/TPS reset

must be performed before proceeding with sensor

testing.

7. Using diagnostic software, document any trouble

codes. Determine if historic trouble codes are

logically related to current fault experienced. If

uncertain, clear codes and retest.

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......