63

Disassembly/Inspection and Service

17 690 15 Rev. --

KohlerEngines.com

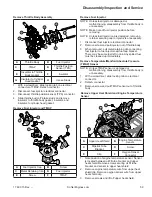

Valve Guides

If a valve guide is worn beyond specifi cations, it will not guide valve in a straight line. This may result in burnt valve

faces or seats, loss of compression, and excessive oil consumption.

To check valve guide-to-valve stem clearance, thoroughly clean valve guide and, using a split-ball gauge, measure

inside diameter of guide. Then, using an outside micrometer, measure diameter of valve stem at several points on

stem where it moves in valve guide. Use largest stem diameter to calculate clearance by subtracting stem diameter

from guide diameter. If intake or exhaust clearance exceeds specifi cations in Valve Specifi cation table, determine

whether valve stem or guide is responsible for excessive clearance.

If guides are within limits but valve stems are worn beyond limits, install new valves.

Valve Seat Inserts

Hardened steel alloy intake and exhaust valve seat inserts are press-fi tted into cylinder head. Inserts are not

replaceable but can be reconditioned if not too badly pitted or distorted. If cracked or badly warped, cylinder head

should be replaced.

Recondition valve seat inserts following instructions provided with valve seat cutter being used. Final cut should be

made with a 44.5° cutter as specifi ed for valve seat angle. Cutting proper 45° valve face angle, as specifi ed, and

proper valve seat angle (44.5°) will achieve desired 0.5° (1.0° full cut) interference angle where maximum pressure

occurs on outside diameters of valve face and seat.

Lapping Valves

Reground or new valves must be lapped in, to provide proper fi t. Use a hand valve lapping tool with suction cup

for fi nal lapping. Lightly coat valve face with fi ne grade of grinding compound, then rotate valve on seat with tool.

Continue lapping until smooth surface is obtained on seat and on valve face. Thoroughly clean cylinder head in soap

and hot water to remove all traces of grinding compound. After drying cylinder head, apply a light coating of SAE 10

oil to prevent rusting.

Valve Stem Seals

These engines use valve stem seals on intake and exhaust valves.

Always use new seals when valves are removed from cylinder head. Seals should also be replaced if deteriorated or

damaged in any way. Never reuse old seals.

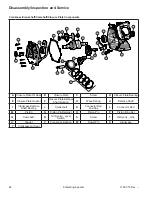

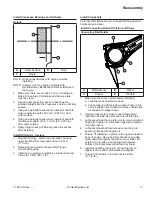

Valve Details

D

D

A

C

D

E

E

B

Valve Specifi cations

Item

Dimension

Intake

Exhaust

A

Head Diameter

35.875-36.125 mm

(1.4124-1.4222 in.)

32.875-33.125 mm

(1.2943-1.3041 in.)

B

Valve Length

86.175-86.375 mm

(3.3927-3.4006 in.)

86.341-86.541 mm

(3.3993-3.4071 in.)

C

Stem Diameter

6.560-6.575 mm

(0.2583-0.2589 in.)

6.545-6.560 mm

(0.2577-0.2583 in.)

D

Face/Seat Width - Maximum

1.5 mm (0.059 in.)

1.5 mm (0.059 in.)

E

Face/Seat Angle

45°-44.5°

45°-44.5°

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......