EFI SYSTEM

34

17 690 15 Rev. --

KohlerEngines.com

Sensor Signal Observation

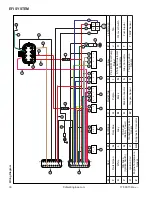

Engine Harness O2 Sensor Connector Plug Detail

D

B C

A

A

Red w/Black Stripe

B

Dark Green

C

Purple

D

Black

NOTE:

Do not cut into or pierce sensor or engine

wiring to make this connection.

Sensor

produces a very small signal. Corrosion or

damage to wiring could lead to an incorrect

signal because of repairs or contamination to

sensor.

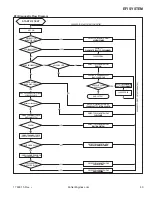

1. With sensor connected and using diagnostic

software, start engine to observe O2 sensor activity.

Run engine at suffi cient speed to bring sensor and

engine up to operating temperature (engine

temperature of 150°F (66°C) or more displayed by

diagnostic software).

Maintained throttle openings of less than 37%

typically display closed loop operation where sensor

output voltage should cycle between 0.05 to 0.95

Volts.

Maintained throttle openings of 38-50% and above

typically display open loop operation where sensor

should have above 0.500 Volt. Occasional spikes

outside these values is normal. Lack of continuous

fl uctuation is not an indication of a defective sensor.

2. With key ON and engine OFF, sensor connected,

using diagnostic software, O2 volts displayed should

be more than 1.0 volt. This voltage is generated by

ECU. If not present, there may be a power and/or

ground supply fault to engine harness or ECU, a

fault of engine harness itself (refer to Visual

Inspection), or a fault of ECU.

With key ON and sensor unplugged, using a digital

voltmeter, observe voltage between Pin socket C

and Pin socket D of engine wiring harness (refer to

engine harness connector plug detail at top of page).

Voltage should read approximately 5.0 volts.

3. Using a digital voltmeter, observe system sensor

voltage between Pin socket A and negative (-)

battery ground. Battery voltage should be seen. If

battery voltage is not seen, inspect engine wiring,

fuses, and/or electrical connections.

Removal Inspection

NOTE: Apply anti-seize compound only to threads.

Anti-seize compound will aff ect sensor

performance if it gets into lower shield of

sensor.

1. If sensor has heavy deposits on lower shield,

engine, oil, or fuel may be source.

2. If heavy carbon deposits are observed, incorrect

engine fuel control may be occurring.

3. With sensor at room temperature, measure heater

circuit resistance, purple wire (Pin A) and white wire

(Pin B).

Resistance should be 16.5-19.5 Ω.

4. If a damaged sensor is found, identify root cause,

which may be elsewhere in application. Refer to

Troubleshooting-Oxygen (O2) Sensor table.

5. A special "dry to touch" anti-seize compound is

applied to all new oxygen sensors at factory. If

recommended mounting thread sizes are used, this

material provides excellent anti-seize capabilities

and no additional anti-seize is needed. If sensor is

removed from engine and reinstalled, anti-seize

compound should be reapplied. Use an oxygen

sensor safe type anti-seize compound. It should be

applied according to directions on label. Torque

sensor to 18 N·m (159 in. lb.).

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......