SECTION 17 — ELECTRIC VEHICLE - TRANSAXLE

17

Electric Vehicle - Transaxle

DANGER

• See General Warnings on page 1-1.

WARNING

• See General Warnings on page 1-1.

LUBRICATION

See General Warnings on page 1-1.

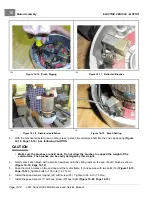

There are two plugs located on the lower half of the transaxle housing. The upper plug (21) (as viewed when the

vehicle is on a level surface) is used as a lubricant level indicator

. When the vehicle

is parked on a level surface, the lubricant level should be even with the bottom of the hole. The lower plug (22) is

for draining the lubricant. When draining the lubricant, the upper plug should be removed so the lubricant will drain

faster. Be sure the drain plug is installed before filling.

See following NOTE.

NOTE:

Recycle or dispose of used oil or lubricant in accordance with local, state, and federal regulations.

AXLE BEARING AND SHAFT

See General Warnings on page 1-1.

AXLE SHAFT

Axle Shaft and Oil Seal Removal

1.

Disconnect the batteries and discharge the controller.

See Disconnect the Batteries – Electric Vehicles,

2.

Place chocks at the front wheels. Loosen lug nuts on rear wheels and lift the rear of the vehicle with a chain

hoist or floor jack. Place jack stands under the axle tubes to support the vehicle.

See WARNING “Lift only one

end...” in General Warnings on page 1-1.

3.

Remove the rear wheel and brake drum.

See Wheel Brake Assemblies Section and Wheels and Tires Section.

4.

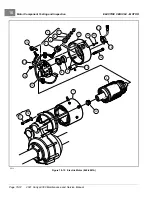

Use 90° internal snap ring pliers to remove the internal retaining ring (1) from the axle tube

.

5.

Remove the axle (2), retaining ring, and bearing assembly by pulling the axle straight out of the housing.

6.

If necessary, remove the axle oil seal and adapter ring.

6.1.

Use a bearing puller to remove the axle seal and adapter ring from the axle tube

See following CAUTION and NOTE.

CAUTION

• Do not scar or damage the inside surfaces of the tube when removing the oil seal and adapter ring. A

damaged tube might have to be replaced.

NOTE:

Do not discard the adapter ring. If the adapter ring is lost or damaged, the axle tube will have to be replaced.

2021 Carryall 300 Maintenance and Service Manual

Page 17-1

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......