31

17 690 15 Rev. --

KohlerEngines.com

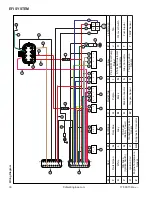

EFI SYSTEM

Crankshaft Position Sensor

A sealed, non-serviceable assembly. If fault code P0337

is present and engine does not start/run, proceed to step

1. If P0337 is present and engine operates, clear codes

and retest. If Fault Code diagnosis indicates a problem

within this area, test and correct as follows.

1. Inspect wiring and connections for damage or

problems.

2. Make sure engine has resistor type spark plug.

3. Disconnect Black connector from ECU.

4. Connect an ohmmeter between #4 and #13 pin

terminals. A resistance value of 325-395 Ω at room

temperature (20°C, 68°F) should be obtained. If

resistance is correct, remove blower housing to

check sensor mounting, fl ywheel teeth (damage,

run-out, etc.), and fl ywheel key. Follow procedures in

Disassembly to remove blower housing.

5. Disconnect crankshaft position sensor connector

from wiring harness. Test resistance between

terminals. A reading of 325-395 Ω should again be

obtained.

a. If resistance is incorrect, remove screw securing

sensor to bracket and replace sensor.

b. If resistance in step 4 was incorrect, but

resistance of sensor alone was correct, test wire

harness circuits between sensor connector

terminals and corresponding pin terminals (#4

and #13) in main connector. Correct any

observed problem, reconnect sensor, and

perform step 4 again.

6. When fault is corrected and engine starts, clear fault

codes following ECU Reset procedure.

Throttle Position Sensor (TPS)

TPS is a sealed, non-serviceable assembly. If diagnosis

indicates a bad sensor, complete replacement is

necessary. If a fault code indicates a problem with TPS,

it can be tested as follows:

Diagnostics of sensor: ECU will have electrical faults

captured in fault codes P0122 and P0123. Fault code

P0122 detecting low voltage, open circuit, and P0123 for

high voltage conditions between ECU, wire harness, and

sensor. Tip: when working with any electrical connection,

remember to keep connections clean & dry. This is best

accomplished by cleaning connection thoroughly prior

to disassembly. Contaminated sensor connections can

cause premature engine faults. Functionally testing

sensor cannot be done with simple resistance checks.

If either of these two faults is present or a TPS fault is

suspected, recommended diagnostic test is as follows:

If a computer with diagnostic software is available

Observe throttle percent and raw TPS values through

diagnostic software. With diagnostic software

communicating to ECU and key ON engine not running,

these values can be observed while throttle is moved

from closed to full open position. There should be a

smooth and repeatable throttle percent value starting

at closed position reading between 0 and 3% to WOT

position reading of 93 to 100%. If one of these values

is outside of specifi ed range and output transitions in a

smooth manner, reset ECU and run test again.

Since there is no longer any wear elements inside

sensor, most likely faults will be in electrical connections

between sensor and wire harness and wire harness to

ECU. With service software communicating to ECU and

engine not running, a small load or gentle back and forth

motion can be applied to connectors or wires just outside

connectors to detect a faulty connection.

I

f only a volt meter is available

Measure voltage supply to sensor from ECU. This

voltage should be 5.00 +/- 0.20 volts. This can be

measured by gently probing terminals B & C on harness

side with TPS connector removed from TPS and key

ON. This will generate a P0122 fault that can be cleared

with an ECU reset. If voltage is low, battery, harness and

ECU should be investigated. If supply voltage is good,

plug sensor back into harness. Probe sensor signal

wire with volt meter, terminal A at TPS or pin Black 12 at

ECU. This signal should start between 0.6-1.2 volts at

low idle and grow smoothly as throttle is opened to 4.3-

4.8 volts at full open (WOT). Since there is no longer any

wear elements inside sensor, most likely faults will be in

electrical connections between sensor and wire harness

and wire harness to ECU.

Replace TPS

C

D

C

A

B

A

A

TPS Screws

B

TPS

C

Magnet Assembly

D

Magnet Installation

Depth

Magnet assembly is captured in a small plastic housing

that is press fi t to end of throttle shaft. If replacement is

required, it can be replaced as follows:

1. Remove screws securing TPS to throttle body.

Remove sensor from throttle body, exposing round

magnet assembly.

2. A pair of fl at blade screw drivers or a spanner tool

can be used to pry this off shaft. Caution should be

used to avoid damage to machined fl at surface that

sensor seals against. Also, make sure throttle blade

is in full open position to avoid driving throttle blade

into throttle bore causing damage to blade and/or

bore.

3. When replacing magnet assembly, alignment is

critical. There is a D-shaped drive feature on end of

shaft and a matching pocket in magnet assembly.

On outer diameter of magnet assembly is a notch

that aligns with center of fl at feature of D. Align this

notch and fl at of D feature in shaft and preassemble

parts.

Summary of Contents for Carryall 300 2021

Page 2: ......

Page 16: ......

Page 551: ...80 2018 by Kohler Co All rights reserved KohlerEngines com 17 690 15 Rev...

Page 565: ...GASOLINE ENGINE HARNESS Wiring Diagrams Gasoline Engine Harness 26...

Page 566: ...Page intentionally left blank...

Page 567: ...GASOLINE KEY START MAIN HARNESS Wiring Diagrams Gasoline Key Start Main Harness 26...

Page 568: ...Page intentionally left blank...

Page 569: ...GASOLINE PEDAL START MAIN HARNESS Wiring Diagrams Gasoline Pedal Start Main Harness 26...

Page 570: ...Page intentionally left blank...

Page 571: ...GASOLINE INSTRUMENT PANEL HARNESS Wiring Diagrams Gasoline Instrument Panel Harness 26...

Page 572: ...Page intentionally left blank...

Page 573: ...GASOLINE FNR HARNESS Wiring Diagrams Gasoline FNR Harness 26...

Page 574: ...Page intentionally left blank...

Page 575: ...ELECTRIC MAIN HARNESS Wiring Diagrams Electric Main Harness 26...

Page 576: ...Page intentionally left blank...

Page 577: ...ELECTRIC INSTRUMENT PANEL HARNESS Wiring Diagrams Electric Instrument Panel Harness 26...

Page 578: ...Page intentionally left blank...

Page 579: ...ELECTRIC ACCESSORIES HARNESS Wiring Diagrams Electric Accessories Harness 26...

Page 580: ...Page intentionally left blank...

Page 588: ...NOTES...

Page 589: ...NOTES...

Page 590: ...NOTES...

Page 591: ...NOTES...

Page 592: ...NOTES...

Page 593: ...NOTES...

Page 594: ...NOTES...

Page 595: ......

Page 596: ......