156

ERROR

CODE

Description

Measures *1

E618 *3, *4

The marking spacing is too small.

• When Trigger mode is set to Marking at regular

intervals, set the larger value to Marking spacing.

• When Trigger mode is set to Multiple triggers, take

more time for the trigger input intervals.

• Decrease the line speed.

• Set Lasing start boundary to the upward of the

moving direction.

• When Trigger mode is set to Multiple triggers,

check the switch or the sensor connected to

TRIGGER IN of I/O terminal operates properly

without chattering.

• Reduce the marking time with the following

measures.

• Increase the scan speed.

• Reduce the spacing between the characters.

• Reduce the character size.

• Set smaller value to the one-shot pulse

duration of the I/O settings, etc.

E619 *3, *4

On-the-fly marking is not possible with this

trigger detecting position or lasing start

boundary.

• Place the lasing start boundary downstream of the

trigger detecting position.

• Check the setting value of Workpiece reference

boundary is correct.

E620 - E621

The link control between the laser marker and

image checker has failed due to the error of the

laser marker. Trigger processing terminated

abnormally.

Check the connection of the cable and various signal

lines, and then restart the laser marker.

E622

I/O connector TIMING IN was not input within

the time specified using the link function with

external devices. Trigger processing terminated

abnormally.

• Input this to TIMING IN terminal within 60 seconds

after the I/O connector timing waiting output

(TIMING WAIT OUT) is turned ON.

• Check the connection of TIMING IN terminal of I/

O connector.

• Check the connection with the external device.

• Check the control procedure of the external

control.

E623

Timing input is invalid.

When the linkage function with external devices

is used, TIMING IN terminal was input while the

timing standby output (TIMING WAIT OUT) was

OFF.

E624

Unable to communicate with an image checker.

Trigger processing terminated abnormally.

• Check the status of connection with the laser

marker and the Ethernet ports of external devices.

• Check the IP address, port number, connecting

status of the laser marking system and image

checker.

• Check the status of the laser marker and external

devices in link control.

• Confirm if you set the type of the image checker

correctly in the system settings screen and file

settings of the settings screen of the laser marker.

ME-LP-GS-SR-COMP-3

Summary of Contents for LP-GS Series

Page 11: ...1 Preparation of Command Control ME LP GS SR COMP 3...

Page 26: ...2 Communication Control Basics ME LP GS SR COMP 3...

Page 50: ...3 Data Format for Each Command ME LP GS SR COMP 3...

Page 136: ...136 MEMO ME LP GS SR COMP 3...

Page 137: ...Troubleshooting ME LP GS SR COMP 3...

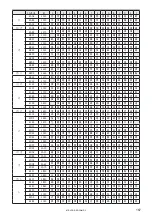

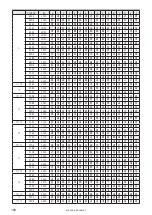

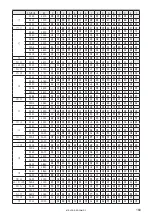

Page 163: ...Character Code Table ME LP GS SR COMP 3...

Page 176: ...Index ME LP GS SR COMP 3...

Page 178: ...178 W Warning 154 ME LP GS SR COMP 3...

Page 179: ......

Page 180: ...Panasonic Industrial Devices SUNX Co Ltd 2014 2019 April 2019...