23. FA TRANSPARENT FUNCTION

23.6 Personal Computer Side Setting

23 - 79

17

ROBOT

CONT

ROLLER

CONN

E

C

TION

18

C

NC CONNECTION

19

ENER

GY M

EAS

URIN

G

UNIT/EL

EC

TRIC M

U

LT

I-

ME

ASUR

ING IN

STRU

MEN

T

CO

NNE

CTION

20

GOT

MUL

T

I-DROP

CONNECTION

21

MUL

TI

PL

E-GT1

4, G

T12,

GT

11

, GT

10

CO

NNECTIO

N FUNCTION

22

MUL

T

I-CHA

N

N

E

L

FUNCT

ION

23

F

A

TRANS

P

ARENT

FUNCTION

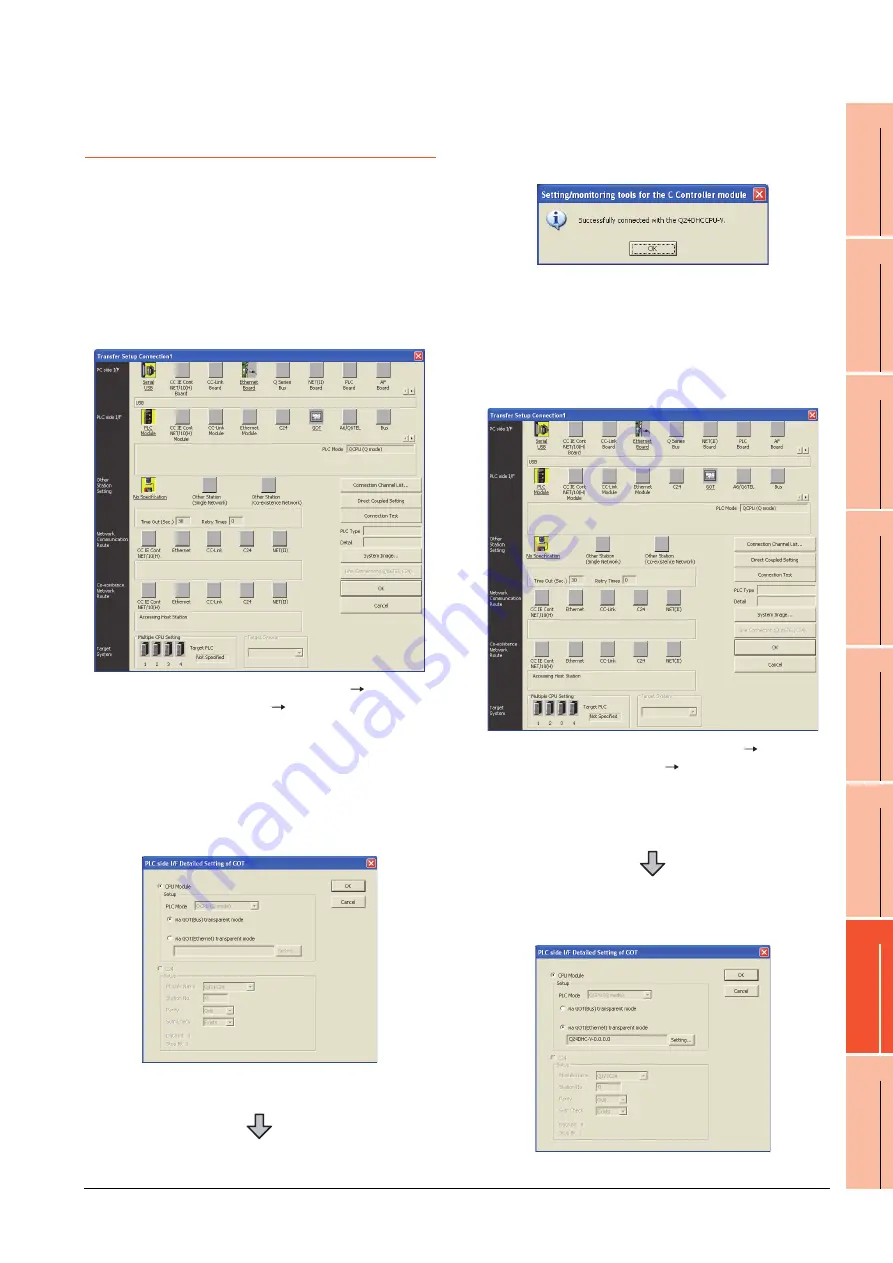

23.6.18 Accessing by Setting/ Monitoring

tool for C Controller module

The following shows the procedure to set the FA

transparent function of Setting/Monitoring tool for C

Controller module with the C Controller module (Q Series)

(Q24DHCCPU-V) connected.

When connecting the GOT and personal

computer with USB

(1) When connecting the GOT and PLC in bus

connection

(2) When connecting the GOT and PLC in Ethernet

communication

1.

Click the Connection Destination view

[Connection Destination]

[(Connection target

data name)] in the Navigation window of MT Setting/

Monitoring tool for C Controller module.

2.

The [Transfer Setup] is displayed.

3.

Set the [Transfer Setup]:

PLC side I/F : GOT

Other station : No specification

4.

Double-click [GOT] of the CPU side I/F to display

[CPU side I/F Detailed Setting of GOT].

5.

Mark the [via GOT(Bus) transparent mode]

checkbox on the [CPU side I/F Detailed Setting of

GOT] screen.

6.

The screen returns to [Transfer Setup]. Click

[Connection Test] to check if Setting/Monitoring tool

for C Controller module has been connected to the

motion controller (Q mode).

1.

Click the Connection Destination view

[Connection Destination]

[(Connection

target

data name)] in the Navigation window of MT Setting/

Monitoring tool for C Controller module.

2.

The [Transfer Setup] is displayed.

3.

Set the [Transfer Setup]:

PLC side I/F : GOT

Other station : No specification

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......