4. HOW TO MONITOR REDUNTANT SYSTEM

4.10 Switch the Monitor Target to the Control System Using the Script Function

4 - 41

1

P

R

EP

ARA

T

OR

Y

P

R

OCEDURES FOR

MONIT

O

R

ING

2

DE

VICE RA

NGE

THA

T

C

A

N

B

E

SET

3

ACCESS

RANGE

F

O

R MONIT

O

RING

4

HOW T

O

MONIT

O

R

REDUNT

ANT

SYS

TE

M

5

BUS CONNECTION

6

DIRE

CT

CONNECTION T

O

CPU

7

COMP

U

T

E

R

LINK

CONNECTION

8

ETHERNE

T

CONNE

C

T

ION

Setting method (Ethernet connection)

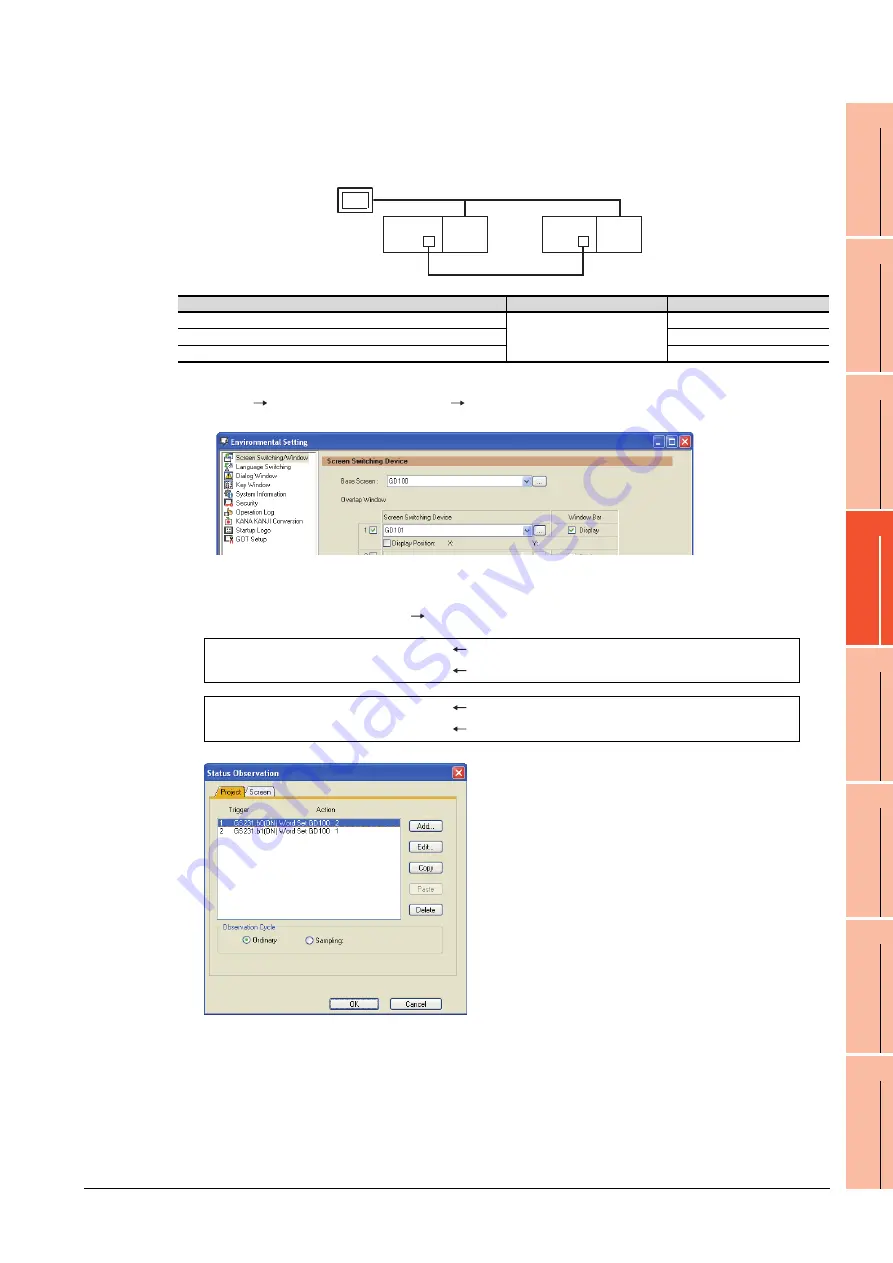

System configuration example 2: Ethernet connection

1.

Set the screen switching device of the base screen.

Select [Common]

[GOT Environmental Setting]

[Screen Switching/Window], and set the internal device

GD100 as the base screen switching device.

2.

Set the status observation.

Make the setting so that the station number is switched when the faulty station information (GS231) from the station

monitoring specified by selecting [Common]

[Status Observation] turns ON.

3.

Set monitor screens.

For MELSECNET/H connection, MELSECNET/10 connection or Ethernet connection: (Common)

• Create a monitor screen with each object whose network setting is Station No. 1 on Screen No. 1 (1-1).

• Create a monitor screen with each object whose network setting is Station No. 2 on Screen No. 2 (1-2).

Ethernet

Network No. 1

GOT

Station No. 3

Control system

(System A)

Q25PRH

CPU

QJ71

E71

Standby system

(System B)

Station No. 1

Q25PRH

CPU

QJ71

E71

Station No. 2

Connected module

Network No.

Station No.

Ethernet module of control system

1

1

Ethernet module of standby system

2

GOT connected to the Ethernet network

3

Condition 1 : GS231.b0 (while ON)

When b0 is ON, Station No. 1 is abnormal.

Operation

: GD100=2

Screen No. is changed to 2.

Condition 1 : GS231.b1 (while ON)

When b1 is ON, Station No. 2 is abnormal.

Operation

: GD100=1

Screen No. is changed to 1.

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......