20. GOT MULTI-DROP CONNECTION

20.6 Setting of Serial Multi-Drop Connection Unit

20 - 27

17

ROBOT

CONT

ROLLER

CONN

E

C

TION

18

C

NC CONNECTION

19

ENER

GY M

EAS

URIN

G

UNIT/EL

EC

TRIC M

U

LT

I-

ME

ASUR

ING IN

STRU

MEN

T

CO

NNE

CTION

20

GOT

MUL

T

I-DROP

CONNECTION

21

MUL

TI

PL

E-GT1

4, G

T12,

GT

11

, GT

10

CO

NNECTIO

N FUNCTION

22

MUL

T

I-CHA

N

N

E

L

FUNCT

ION

23

F

A

TRANS

P

ARENT

FUNCTION

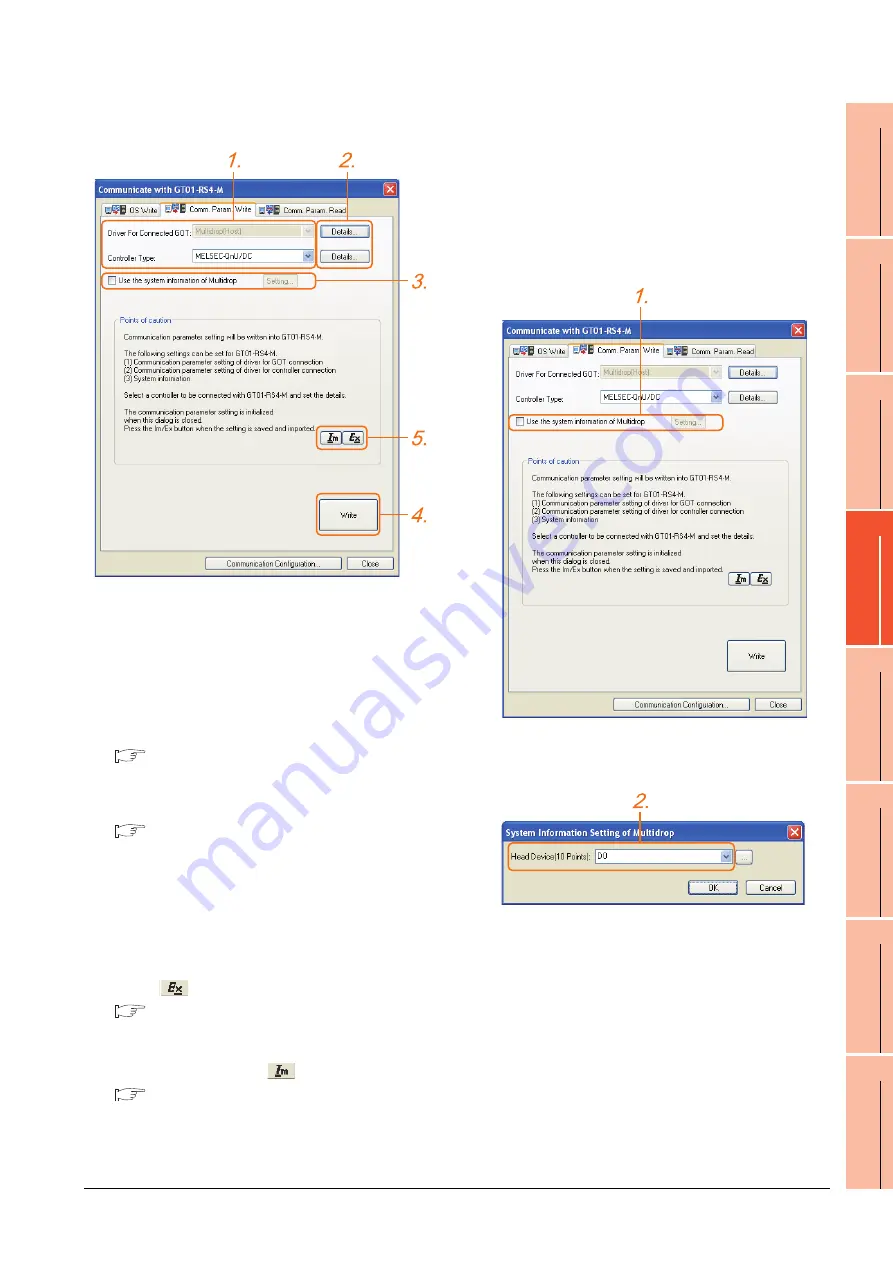

Controller setting

1.

Set the following to the driver for the connected

equipment.

• Connection type dependent

The driver for connection with the GOT is fixed to the

following one.

• Multi-drop(Host)

2.

Perform the detailed settings for the driver.

■

3.

Set [Use the system information of Multidrop] as

necessary.

■

Setting the multi-drop system information

4.

Click the [Write] button when settings are completed.

5.

If the [Communication with GT01-RS4-M] dialog box

is closed, communication setting contents for GT01-

RS4-M does not remain.

• To maintain the communication setting contents,

click

(export).

■

Exporting/Importing the communication

setting contents

• To use communication setting contents which are

saved previously, click

(import).

■

Exporting/Importing the communication

setting contents

Setting the multi-drop system information

function

When checking the connection status of each GOT

which is connected to GT01-RS4-M on the PLC side,

set the multi-drop system information function.

The GOT connection status is stored in the PLC side

word device.

(1) Setting on the PLC side word device

1.

Select [Use the system information of Multidrop] and

click the [Set] button. The following dialog window is

displayed.

2.

Set the PLC side word device to [Head Device (10

Points)]. In this example, "D0" is set.

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......