5. BUS CONNECTION

5.3 GOT Side Settings

5 - 33

1

P

R

EP

ARA

T

OR

Y

P

R

OCEDURES

FOR

MONIT

O

R

ING

2

D

E

VICE RA

NGE

T

H

A

T

CAN

B

E

SET

3

ACCESS

RA

N

G

E

F

O

R MONIT

O

R

ING

4

HOW T

O

MONIT

O

R

REDUNT

ANT

SYS

TEM

5

BUS CONNECTION

6

DIR

E

CT

CONNECTION T

O

CPU

7

COMP

UT

E

R

L

INK

CONNE

C

T

ION

8

E

T

HE

RN

E

T

CONN

E

C

T

ION

POINT

POINT

POINT

(1) Communication interface setting by Utility

The communication interface setting can be changed

on the Utility's [Communication Settings] after writing

[Communication Settings] of project data.

For details on the Utility, refer to the following manual.

GT User's Manual

(2) Precedence in communication settings

When settings are made by GT Designer3 or the

Utility, the latest setting is effective.

(3) When changing Stage No. and Slot No.

Change these settings with the PLC CPU turned

OFF, and then reapply the power to the PLC CPU

and GOT.

Failure to do so may generate a system alarm

(No.487).

HINT

HINT

HINT

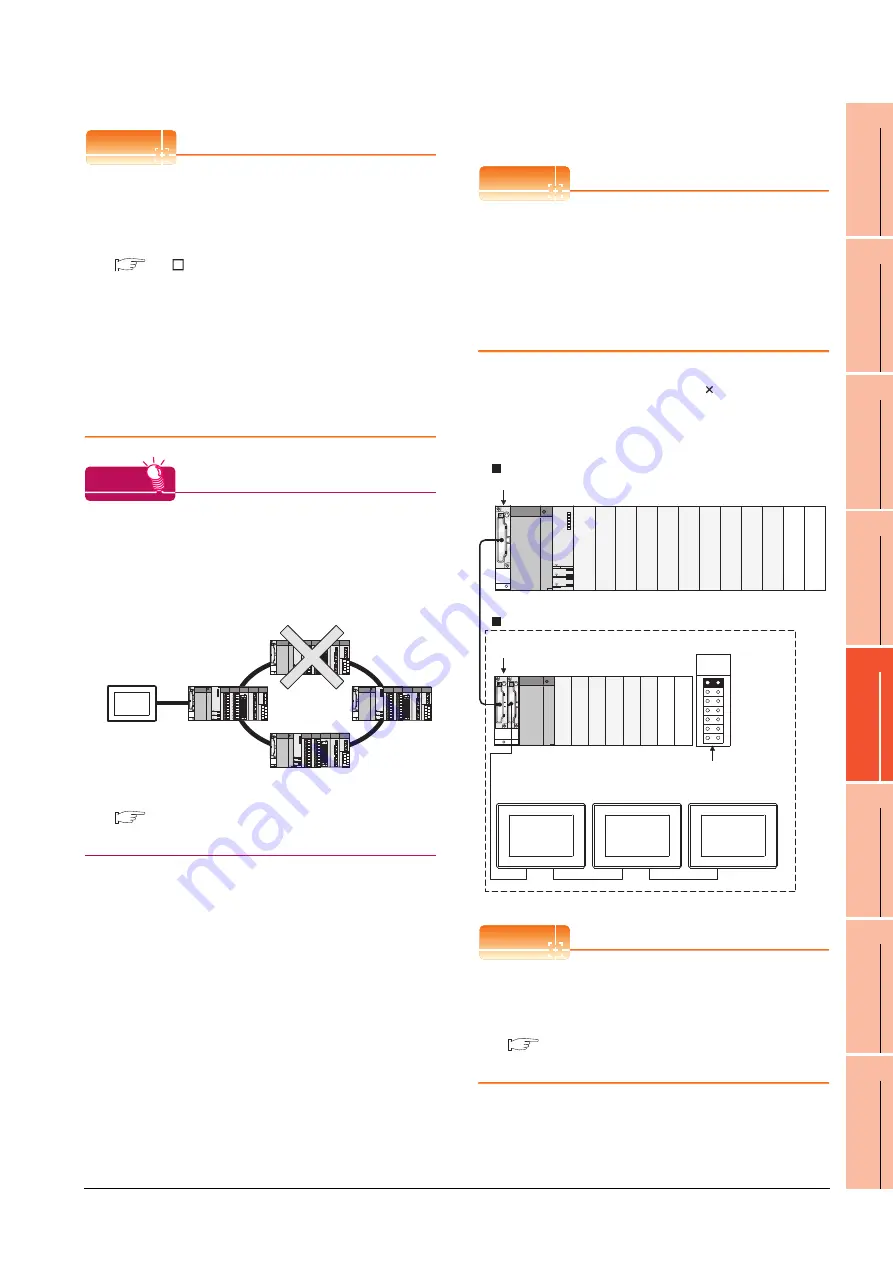

Cutting the portion of multiple connection of the

controller

By setting GOT internal device, GOT can cut the

portion of multiple connection of the controller. For

example, faulty station that has communication

timeout can be cut from the system.

For details of the setting contents of GOT internal

device, refer to the following manual.

GT Designer3 Version Screen Design Manual

(Fundamentals)

Setting Stage No. and Slot No.

POINT

POINT

POINT

Before setting Stage No. and Slot No.

The PLC CPU recognizes the GOT as follows.

• QCPU (Q mode)

: Intelligent function module of 16 I/O points

• Other than QCPU (Q mode)

: Intelligent function module of 32 I/O points

At the [Detail setting], assign the GOT to an empty I/O

slot on the PLC CPU.

(1) When connecting to QCPU (Q mode)

Set an additional stage (16 points 10 slots) for GOT

connection, and assign a GOT to one of the I/O slots.

(The GOT cannot be assigned to empty slots of the

main base unit or extension base unit.)

POINT

POINT

POINT

When using the bus extension connector box

Set the Stage No. switch on the bus extension

connector box to the same Stage No. as the GOT.

For setting details, refer to the following manual:

A9GT-QCNB Bus Extension Connector Box

User's Manual

Disconnect the

faulty station

Q312B

Q68B

Main base unit

Stage No. :2

Slot No. :0

Stage No. :2

Slot No. :1

Stage No. :2

Slot No. :2

Extension base unit

Stage No. setting

connector

Extension

stage 1

Empty

Empty

Empty

Empty

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......