21. MULTIPLE-GT14, GT12, GT11, GT10 CONNECTION FUNCTION

21.4 GOT Side Settings

21 - 7

17

ROBOT

CONT

ROLLER

CONN

E

C

T

ION

18

CNC CONNECTION

19

ENER

GY M

EASU

RIN

G

UNIT/ELEC

TRIC M

UL

TI

-

MEA

S

UR

IN

G IN

STRUM

EN

T

CON

NEC

TION

20

GOT

MUL

T

I-

DROP

CONNECTION

21

M

U

LT

IP

LE

-G

T1

4,

GT

12

,

GT

11

, G

T10

CO

NNEC

TIO

N FUNCTION

22

MUL

T

I-CHANNE

L

FUNC

TION

23

F

A

TRANSP

A

R

ENT

FUNCT

ION

21.4 GOT Side Settings

21.4.1 Setting communication

interface (Communication

settings)

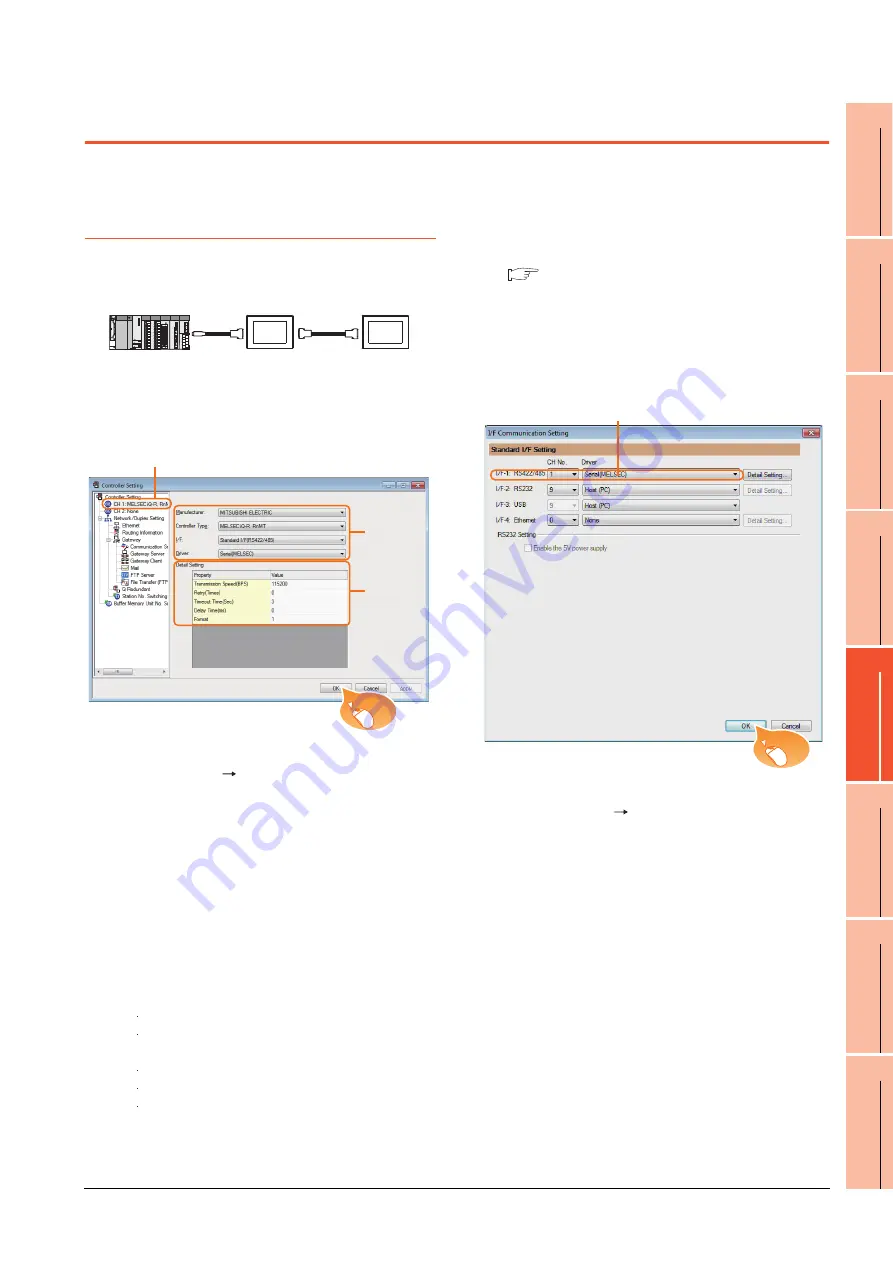

This section explains with an example of the following

system configuration.

Setting for the first GOT

(1) Settings of communication interface connecting to

the PLC

1.

Select [Common] [Controller Setting] from the

menu.

2.

The Controller Setting window is displayed. Select the

channel to be used from the list menu.

3.

Set the following items.

• Manufacturer: MITSUBISHI ELECTRIC

• Controller Type: Set according to the Controller

Type to be connected.

• I/F: Standard I/F (RS-232)

• Driver: Set either of the following according to the

Controller Type to be connected.

For GT14, GT12, GT11

Serial

(MELSEC)

MELSEC-FX

For GT10

Serial

(MELSEC)

MELSEC-A

MELSEC-FX

4.

The detailed setting is displayed after Manufacturer,

Controller Type, I/F, and Driver are set.

Make the settings according to the usage

environment.

21.4.2 Communication detail settings

Click the [OK] button when settings are completed.

(2) Settings of communication interface connecting to

the second GOT

1.

Select [Common] [I/F Communication Setting] from

the menu.

2.

The I/F Connection list window is displayed. Select

the following.

• I/F-1: RS422/232

CH No.: 9

Driver: Host (PC)

Click the [OK] button when settings are completed.

RS-422

cable

RS-232

cable

1st GOT

2nd GOT

GT11

GT11

2.

3.

4.

Click!

2.

Click!

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......