1. PREPARATORY PROCEDURES FOR MONITORING

1.1 Setting the Communication Interface

1 - 15

1

P

R

EP

ARA

T

OR

Y

P

R

OCEDURES

FOR

MONIT

O

R

ING

2

D

E

VICE RA

NGE

T

H

A

T

CAN

B

E

SET

3

ACCESS

RA

N

G

E

F

O

R MONIT

O

R

ING

4

HOW T

O

MONIT

O

R

REDUNT

ANT

SYS

TEM

5

BUS CONNECTION

6

DIR

E

CT

CONNECTION T

O

CPU

7

COMP

UT

E

R

L

INK

CONNE

C

T

ION

8

E

T

HE

RN

E

T

CONN

E

C

T

ION

POINT

POINT

POINT

Channel No., drivers, [RS232 Setting]

(1) Channel No.2 to No.4

Use the channel No.2 to No.4 when using the Multi-channel function.

For details of the Multi-channel function, refer to the following.

Mitsubishi Electric Products 22. MULTI-CHANNEL FUNCTION

(2) Drivers

The displayed items for a driver differ according to the settings [Manufacturer], [Controller Type] and [I/F].

When the driver to be set is not displayed, confirm if [Manufacturer], [Controller Type] and [I/F] are correct.

[Setting the communication] section in each chapter

(3) [RS232 Setting] of GT14

Do not use [RS232 Setting] of GT14 for other than the 5V power feeding to the RS-232/485 signal conversion

adaptor.

For details, refer to the following manual.

GT14 User's Manual 7.11 RS-232/485 Signal Conversion Adaptor

1.1.3

Precautions

(1) When using the multiple CPU system

When using the GOT to monitor the multiple CPU system of other stations, select [MELSEC-Q(Multi)/Q-Motion]

or [MELSEC-QnU, Q17nD/M/NC/DR, CRnD-700] for the type, regardless of the host PLC CPU type (QCPU,

QnACPU, ACPU). When other models are selected, the setting of the CPU No. becomes unavailable.

(2) Precautions for changing model

(a) When devices that cannot be converted are included.

When setting of [Manufacturer] or [Controller Type] is changed, GT Designer3 displays the device that

cannot be converted (no corresponding device type, or excessive setting ranges as [??]. In this case, set

the device again.

(b) When the changed Manufacturer or Controller Type does not correspond to the network.

The network will be set to the host station.

(c) When the Manufacturer or Controller Type is changed to [None]

The GT Designer3 displays the device of the changed channel No. as [??]. In this case, set the device

again.

Since the channel No. is retained, the objects can be reused in other channel No. in a batch by using the

[Device Bach Edit], [CH No. Batch Edit] or [Device List].

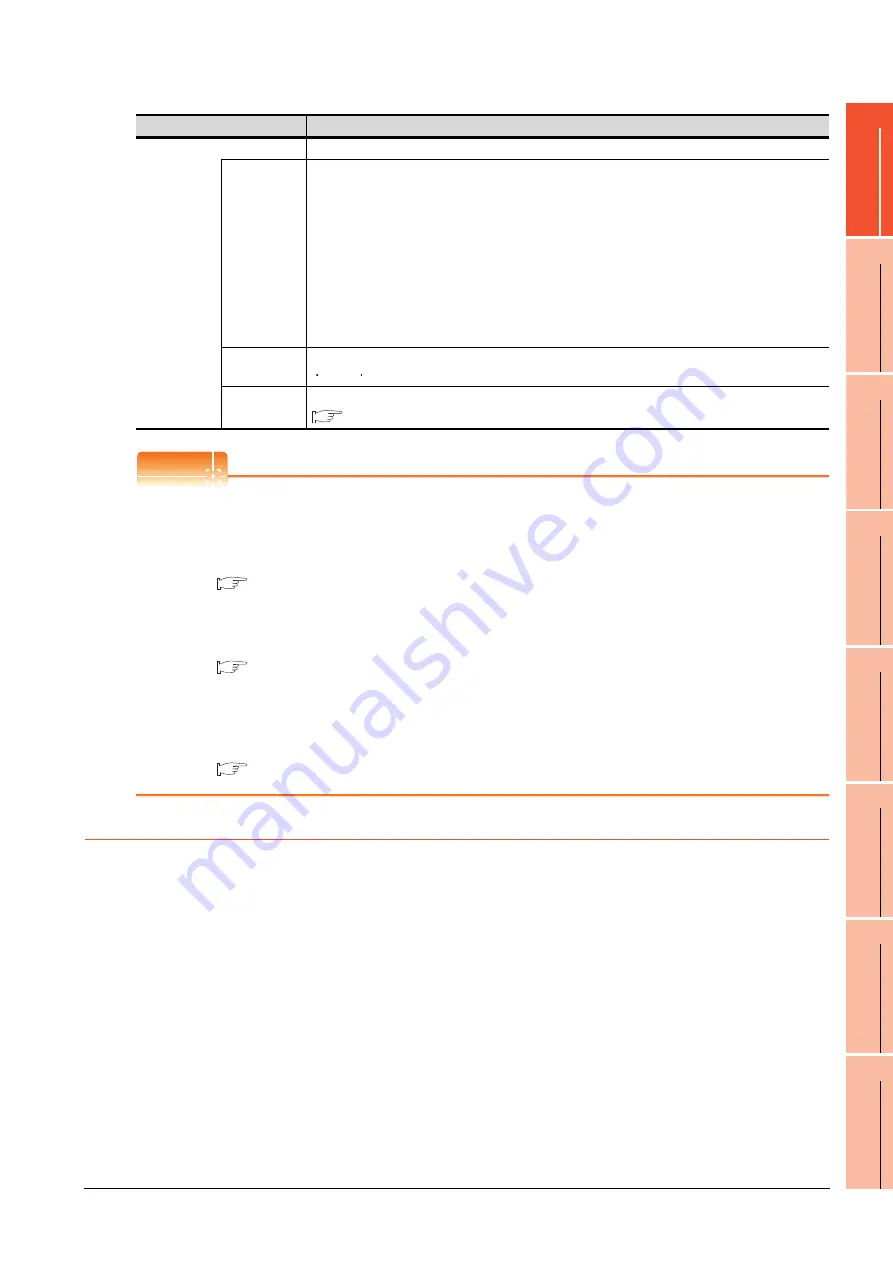

Item

Description

Extension I/F setting

Set the communication unit attached to the extension interface of the GOT.

CH No.

Set the CH No. according to the intended purpose.

The number of channels differs depending on the GOT to be used.

0: Not used

1 to 4: Used for connecting a controller of channel No. 1 to 4 set in Setting connected equipment (Channel

setting)

5 to 7: Used for barcode function, RFID function, remote personal computer operation (serial), report function

(when using the serial printer) or hard copy function (when using the serial printer)

* : Used for remote personal computer operation (Ethernet), video display function, multimedia function,

operation panel function, external I/O function, RGB display function, report function (when using a

PictBridge compatible printer), hard copy function (when using a PictBridge compatible printer), sound

output function, functions with the CF card unit or CF card extension unit, Ethernet download, gateway

function or MES interface function

Driver

Set the driver for the device to be connected.

None Each driver for connected devices

Detail Setting

Make settings for the transmission speed and data length of the communication driver.

Refer to each chapter of the equipment to be connected to the GOT.

Summary of Contents for GT15

Page 2: ......

Page 34: ...A 32 ...

Page 92: ......

Page 110: ...2 18 2 DEVICE RANGE THAT CAN BE SET 2 9 MELSEC WS ...

Page 186: ...5 10 5 BUS CONNECTION 5 2 System Configuration ...

Page 218: ...5 42 5 BUS CONNECTION 5 4 Precautions ...

Page 254: ...6 36 6 DIRECT CONNECTION TO CPU 6 6 Precautions ...

Page 286: ...7 32 7 COMPUTER LINK CONNECTION 7 6 Precautions ...

Page 350: ...8 64 8 ETHERNET CONNECTION 8 5 Precautions ...

Page 368: ...9 18 9 MELSECNET H CONNECTION PLC TO PLC NETWORK 9 5 Precautions ...

Page 420: ...11 26 11 CC Link IE CONTROLLER NETWORK CONNECTION 11 5 Precautions ...

Page 440: ...12 20 12 CC Link IE FIELD NETWORK CONNECTION 12 5 Precautions ...

Page 490: ...13 50 13 CC Link CONNECTION INTELLIGENT DEVICE STATION 13 5 Precautions ...

Page 510: ......

Page 564: ...15 54 15 INVERTER CONNECTION 15 7 Precautions ...

Page 668: ......

Page 712: ...21 12 21 MULTIPLE GT14 GT12 GT11 GT10 CONNECTION FUNCTION 21 5 Precautions ...

Page 713: ...MULTI CHANNEL FUNCTION 22 MULTI CHANNEL FUNCTION 22 1 ...

Page 714: ......

Page 760: ...22 46 22 MULTI CHANNEL FUNCTION 22 5 Multi channel Function Check Sheet ...

Page 761: ...FA TRANSPARENT FUNCTION 23 FA TRANSPARENT FUNCTION 23 1 ...

Page 762: ......

Page 860: ...REVISIONS 4 ...

Page 863: ......