Tip

Fixed values for temperature or pressure are not recommended. Using a fixed temperature or

pressure value may produce inaccurate process data.

Important

Line temperature data is used in several different measurements and calculations. It is possible to

use the internal RTD temperature in some areas and an external temperature in others. The

transmitter stores the internal RTD temperature and the external temperature separately. However,

the transmitter stores only one alternate temperature value, which may be either an external

temperature or the configured fixed value. Accordingly, if you set up polling for temperature in one

area, and digital communications in another, and configure a fixed temperature value in a third, the

fixed value will be overwritten by polling and digital communications, and polling and digital

communications will overwrite each other.

Important

Line pressure data is used in several different measurements and calculations. The transmitter stores

only one pressure value, which may be either the external pressure or the configured fixed value.

Accordingly, if you choose a fixed pressure for some uses, and an external pressure for others, the

external pressure will overwrite the fixed value.

Prerequisites

If you plan to poll an external device, the primary mA output must be wired to support

HART communications.

You must be using gauge pressure.

The pressure device must use the pressure unit that is configured in the transmitter.

If you are using an external temperature device, it must use the temperature unit that is

configured in the transmitter.

Procedure

1.

Choose

Device Tools

>

Configuration

>

Process Measurement

>

API Referral

.

2.

Choose the method to be used to supply temperature data, and perform the

required setup.

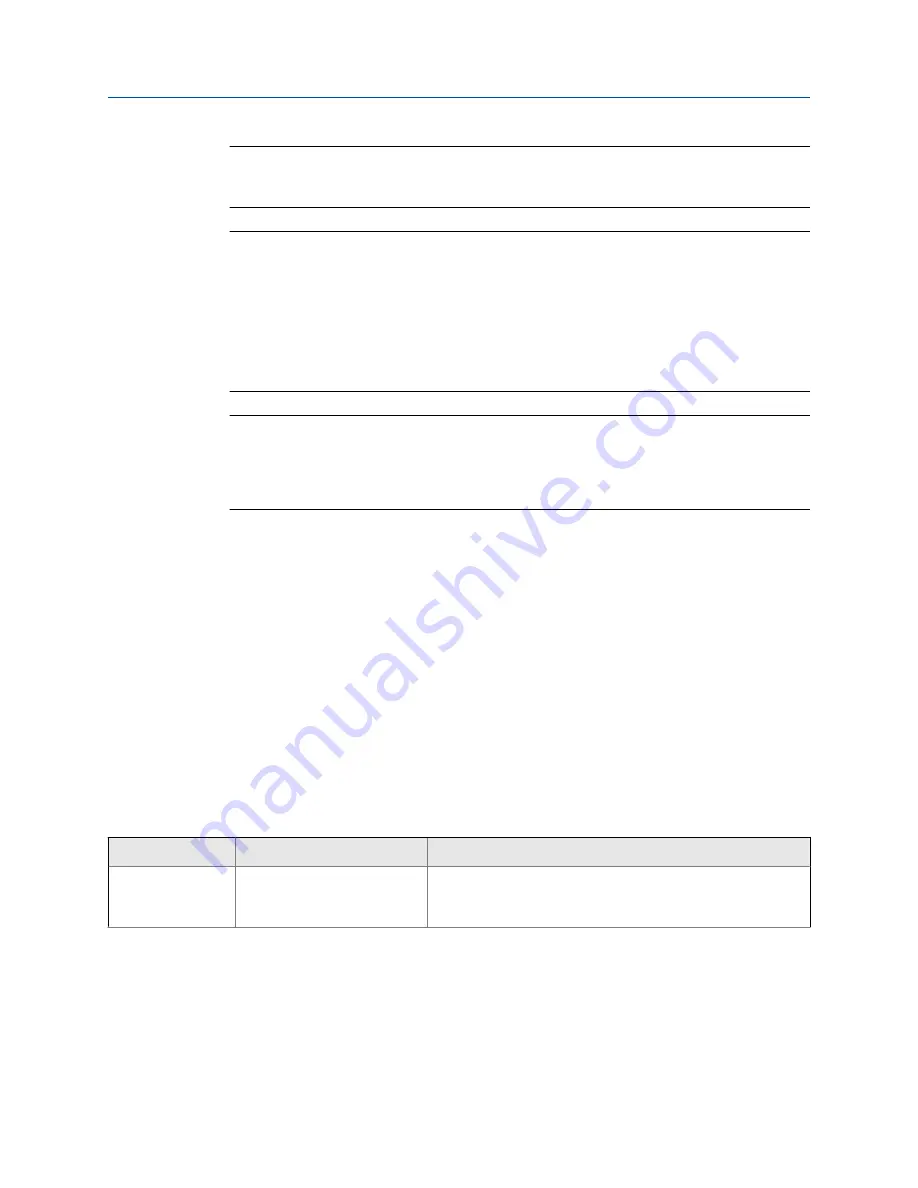

Option

Description

Setup

Internal RTD tem-

perature data

Temperature data from the on-

board temperature sensor

(RTD) is used.

a. Set

Line Temperature Source

to

Internal RTD

.

b. Click

Apply

.

Configure process measurement

48

Micro Motion

®

Compact Density Meters (CDM)

Summary of Contents for CDM100M

Page 8: ...Getting Started 2 Micro Motion Compact Density Meters CDM ...

Page 12: ...Before you begin 6 Micro Motion Compact Density Meters CDM ...

Page 20: ...Configuration and commissioning 14 Micro Motion Compact Density Meters CDM ...

Page 26: ...Introduction to configuration and commissioning 20 Micro Motion Compact Density Meters CDM ...

Page 110: ...Integrate the meter with the control system 104 Micro Motion Compact Density Meters CDM ...

Page 116: ...Operations maintenance and troubleshooting 110 Micro Motion Compact Density Meters CDM ...

Page 124: ...Transmitter operation 118 Micro Motion Compact Density Meters CDM ...

Page 194: ...Using the transmitter display 188 Micro Motion Compact Density Meters CDM ...

Page 208: ...Using ProLink III with the transmitter 202 Micro Motion Compact Density Meters CDM ...