GE Multilin

F60 Feeder Protection System

5-283

5 SETTINGS

5.7 CONTROL ELEMENTS

5

(EQ 5.35)

When current is less than the dropout level,

I

n

> 0.97 ×

k

×

I

B

, the element starts decreasing the thermal energy:

(EQ 5.36)

In the above equations,

•

∆

t

is the power cycle duration

•

n

is the power cycle index

•

t

op

(

In

)

is the trip time calculated at index

n

as per the IEC255-8 cold curve or hot curve equations

•

t

rst

(

In

)

is the reset time calculated at index

n

as per the reset time equation

•

I

n

is the measured overload RMS current at index

n

•

E

n

is the accumulated energy at index

n

•

E

n

– 1

is the accumulated energy at index

n

– 1

The thermal overload protection element removes the

THERMAL PROT 1 OP

output operand when

E

< 0.05. In case of

emergency, the thermal memory and

THERMAL PROT 1 OP

output operand can be reset using

THERM PROT 1 RESET

setting.

All calculations are performed per phase. If the accumulated energy reaches value 1 in any phase, the thermal overload

protection element operates and only resets when energy is less than 0.05 in all three phases.

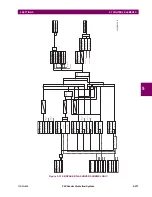

The logic for the thermal overload protection element is shown below.

Figure 5–134: THERMAL OVERLOAD PROTECTION SCHEME LOGIC

Table 5–37: TYPICAL TIME CONSTANTS

PROTECTED EQUIPMENT

TIME CONSTANT

MINIMUM RESET TIME

Capacitor bank

10 minutes

30 minutes

Overhead line

10 minutes

20 minutes

Air-core reactor

40 minutes

30 minutes

Busbar

60 minutes

20 minutes

Underground cable

20 to 60 minutes

60 minutes

E

n

E

n

1

–

t

Δ

t

op In

( )

---------------

+

=

E

n

E

n

1

–

t

Δ

t

rst In

( )

---------------

–

=

SETTINGS

Enabled = 1

Function

Off = 0

Block

AND

SETTING

IA RMS

Source

IB RMS

IC RMS

SETTINGS

IA > k × Ib

K Factor

IB > k × Ib

IC > k × Ic

Base Current

OR

AND

SETTING

Trip Time Constant

RUN

E > 0.1

SETTINGS

Reset Time Constant

RUN

E < 0.1

Minimum Reset Time

Reset E to 0

SETTING

Off = 0

Reset

Latch

S

R

Reset-dominant

FLEXLOGIC OPERAND

THERMAL PROT 1 OP

FLEXLOGIC OPERAND

THERMAL PROT 1 PKP

827013A1.CDR

Summary of Contents for F60

Page 10: ...x F60 Feeder Protection System GE Multilin TABLE OF CONTENTS ...

Page 30: ...1 20 F60 Feeder Protection System GE Multilin 1 5 USING THE RELAY 1 GETTING STARTED 1 ...

Page 138: ...4 28 F60 Feeder Protection System GE Multilin 4 2 FACEPLATE INTERFACE 4 HUMAN INTERFACES 4 ...

Page 454: ...5 316 F60 Feeder Protection System GE Multilin 5 10 TESTING 5 SETTINGS 5 ...

Page 500: ...7 14 F60 Feeder Protection System GE Multilin 7 1 COMMANDS 7 COMMANDS AND TARGETS 7 ...

Page 508: ...8 8 F60 Feeder Protection System GE Multilin 8 2 FAULT LOCATOR 8 THEORY OF OPERATION 8 ...

Page 522: ...10 12 F60 Feeder Protection System GE Multilin 10 6 DISPOSAL 10 MAINTENANCE 10 ...

Page 660: ...B 116 F60 Feeder Protection System GE Multilin B 4 MEMORY MAPPING APPENDIX B B ...

Page 706: ...E 10 F60 Feeder Protection System GE Multilin E 1 IEC 60870 5 104 APPENDIX E E ...

Page 718: ...F 12 F60 Feeder Protection System GE Multilin F 2 DNP POINT LISTS APPENDIX F F ...

Page 728: ...H 8 F60 Feeder Protection System GE Multilin H 2 ABBREVIATIONS APPENDIX H H Z Impedance Zone ...

Page 730: ...H 10 F60 Feeder Protection System GE Multilin H 3 WARRANTY APPENDIX H H ...