Chapter 1

1-22

10) Clean the metal part located next to the rubber roller with a cloth dampened with water. Then, wipe the area with a soft, dry cloth.

F-1-18

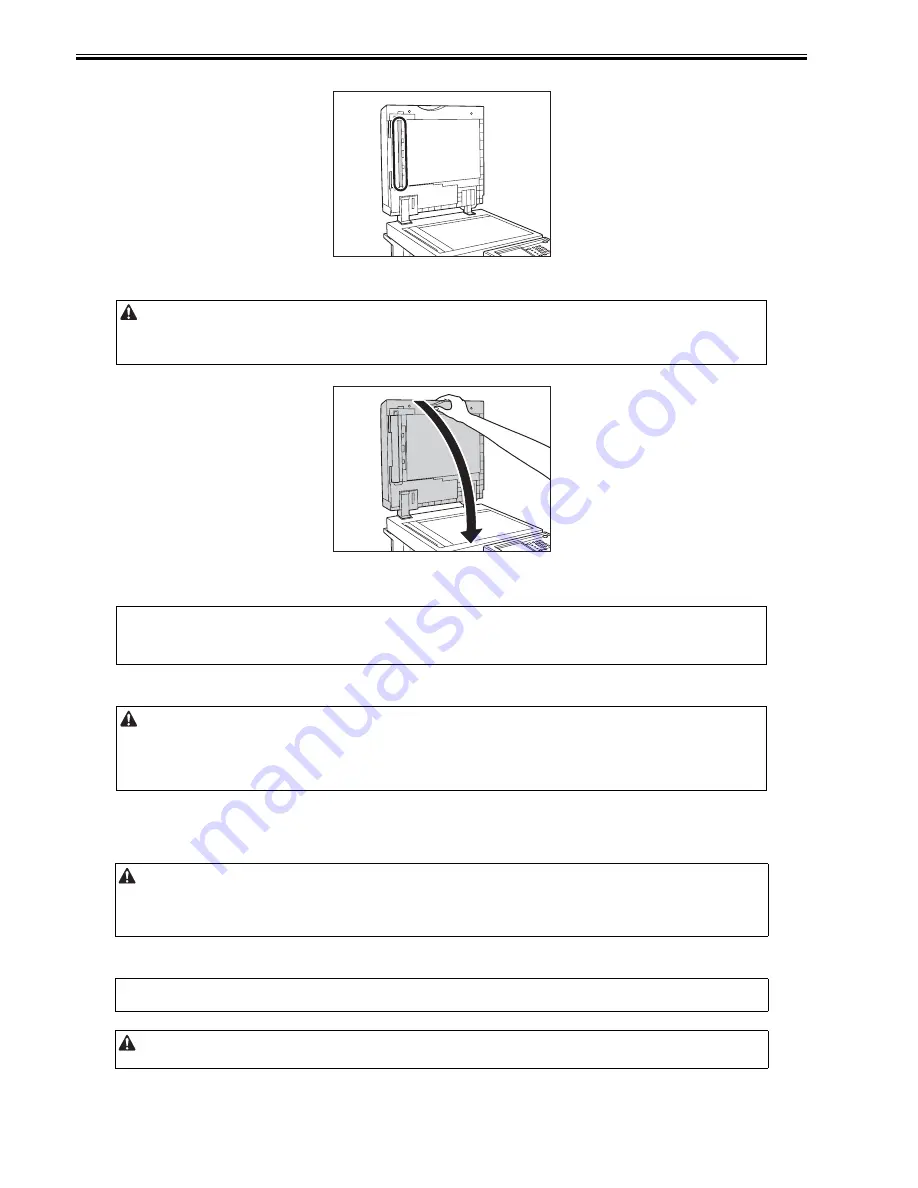

11) Close the feeder.

F-1-19

3. Automatic Feeder Cleaning

If your originals have black streaks or appear dirty after scanning them through the feeder, clean the rollers of the feeder.

1) Press (Additional Functions) -> [Adjustment/Cleaning] -> [Feeder Cleaning].

2) Place 10 sheets of blank paper into the feeder -> press [Start].

1.2.4.2 Inspection

0018-9690

iR3225 / iR3225N / iR3235 / iR3235N / iR3245 / iR3245N

This machine has a breaker that detects excess current or leakage current. Be sure to test the breaker once or twice a month using the following procedure.

Checking the Breaker

1) Push the test button on the rear of the machine with the tip of a ball-point pen, or a similar object.

2) Confirm that the breaker lever is switched to the OFF position.

- When closing the feeder, be careful not to get your fingers caught, as this may result in personal injury.

- Be aware that the light emitted from the platen glass may be very bright when closing the feeder.

MEMO:

-

This procedure is necessary only if the optional Feeder (DADF-U1) (standard-equipped for the imageRUNNER 3245/3245i/3235i/3235i) is attached.

- It takes approximately 20 seconds to clean the feeder.

- Make sure that you fan the sheets of paper well.

- Use LTR paper (16 to 20 lb bond (60 to 80 g/m2)).

- When cleaning is complete, try scanning again.

- To cancel feeder cleaning while it is in progress, press [Cancel].

- Make sure that the main power is turned OFF, before inspecting the breaker.

- Be sure to turn off the main power switch after executing shutdown sequence (to protect HDD).

- If a malfunction occurs after an inspection, contact your local authorized Canon dealer.

MEMO:

The breaker is located on the rear of the machine.

Briefly push the test button.

Summary of Contents for iR3245

Page 1: ...Jul 3 2008 Service Manual iR3245 3235 3230 3225 Series...

Page 2: ......

Page 6: ......

Page 25: ...Chapter 1 Introduction...

Page 26: ......

Page 28: ......

Page 64: ......

Page 65: ...Chapter 2 Installation...

Page 66: ......

Page 120: ......

Page 121: ...Chapter 3 Basic Operation...

Page 122: ......

Page 124: ......

Page 128: ......

Page 129: ...Chapter 4 Main Controller...

Page 130: ......

Page 132: ......

Page 134: ...Chapter 4 4 2 F 4 1 1 5 8 9 11 14 12 3 4 10 2 13 7 15 16 17...

Page 152: ......

Page 153: ...Chapter 5 Original Exposure System...

Page 154: ......

Page 184: ......

Page 185: ...Chapter 6 Laser Exposure...

Page 186: ......

Page 188: ......

Page 197: ...Chapter 7 Image Formation...

Page 198: ......

Page 227: ...Chapter 8 Pickup Feeding System...

Page 228: ......

Page 232: ......

Page 244: ...Chapter 8 8 12 For iR3245 3235 3230 F 8 14 1 2 3 4...

Page 261: ...Chapter 8 8 29 10 11 12 13 14 3 1 2 4 5 4 4 1 2 3 5 4 1 2 3 5 5 4 1 2 3 5 4 1 2 3 5...

Page 278: ......

Page 279: ...Chapter 9 Fixing System...

Page 280: ......

Page 282: ......

Page 297: ...Chapter 10 External and Controls...

Page 298: ......

Page 302: ......

Page 315: ...Chapter 10 10 13 2 Uncheck SNMP Status Enabled F 10 11...

Page 342: ......

Page 343: ...Chapter 11 MEAP...

Page 344: ......

Page 346: ......

Page 397: ...Chapter 12 e maintenance imageWARE Remote...

Page 398: ......

Page 400: ......

Page 408: ......

Page 409: ...Chapter 13 Maintenance and Inspection...

Page 410: ......

Page 412: ......

Page 424: ...Chapter 13 13 12...

Page 425: ...Chapter 14 Standards and Adjustments...

Page 426: ......

Page 428: ......

Page 436: ......

Page 437: ...Chapter 15 Correcting Faulty Images...

Page 438: ......

Page 440: ......

Page 465: ...Chapter 16 Self Diagnosis...

Page 466: ......

Page 468: ......

Page 493: ...Chapter 17 Service Mode...

Page 494: ......

Page 498: ......

Page 690: ......

Page 691: ...Chapter 18 Upgrading...

Page 692: ......

Page 694: ......

Page 738: ...Chapter 18 18 44...

Page 739: ...Chapter 19 Service Tools...

Page 740: ......

Page 742: ......

Page 744: ......

Page 745: ...Jul 3 2008...

Page 746: ......