Chapter 8 Program

8-35

(a) Condition of Point Operation

Condition of Point Operation Command (XPST) Point Operation Step Writing (XPWR)

XPWR has to be done before execute the Point Operation.

(b) Axis ready status

If communication between positioning module and servo drive is done, the signal corresponding to each signal

will be on.

(c) Operating state by axis

According to exercise from “Chapter 8.1.2 Current State Reading,” it is a signal of “Operating” for each axis. It

turns on when it is operating. Point operation start command can not be configured while it is running hence

configuration will only be configured when it is not running. If you execute Point Operation while it is running,

the “error 231” would be appeared.

(d) Error state for each axis

According to exercise from “Chapter 8.1.2 Current State Reading,” it is a signal of “Error state” for each axis. It

turns on when an er ror occurred. Operation will only work when there is no error. If you want to operate a

system regardless of errors, you can just inactivate the function.

(e) Servo On signal

When applying the example program of “8.1.2 Current State Read”, this is “Servo On” signal for each axis.

When each axis is Servo On state, it will be on. Since “Point operation start” command can’t be executed

when the axis is not servo on, it makes command executed when servo driver is “Servo On” state.

(f) Address of Positioning Module

In this example, Positioning Module installed at the slot no.3 of 0 bases.

(g) Axis of command execution

You can set an axis for Point Operation. XBF-PN04(8)B can supports for 4(8) axes. In the “execution of axis”

from the configuration of Point Operation, you can set a value for axis 1 through 4(8) axis.

(h) Address of first device where those data for Step Numbers of Point Operation are saved

To execute a Point Operation, you need to set a specific value first. XPWR commands are using for set up

those Point Operation steps. It has to be done before actual Point Operation. Point Operation Step Data will be

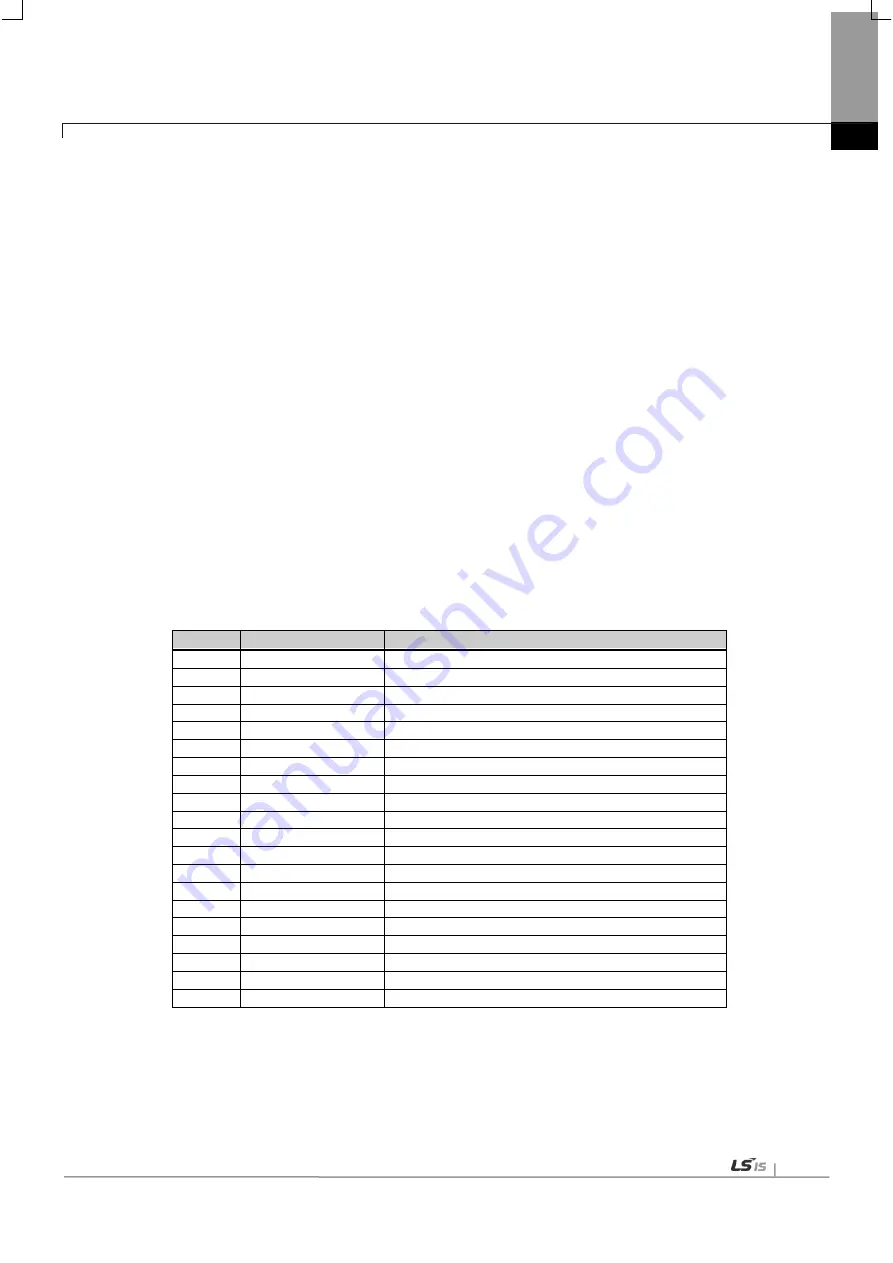

set up depends on number of first device as below table.

Value

Device No.

Point start step data

1

0

Point start step data 1

2

1

Point start step data 2

3

2

Point start step data 3

4

3

Point start step data 4

5

4

Point start step data 5

6

5

Point start step data 6

7

6

Point start step data 7

8

7

Point start step data 8

9

8

Point start step data 9

10

9

Point start step data 10

11

10

Point start step data 11

12

11

Point start step data 12

13

12

Point start step data 13

14

13

Point start step data 14

15

14

Point start step data 15

16

15

Point start step data16

17

16

Point start step data17

18

17

Point start step data18

19

18

Point start step data19

20

19

Point start step data20

(i) Amount of Saving Point Operation Steps

Decide how many data will be saved by using XTWR command. In this example above, 10 Point Operation

steps are saved in the axis 1. Therefore those Step data from D01450~D01459 are saved in the module.

(j) Number of Operation amount by Point Operation

Set the number of saving Step numbers by Point Operating Writing command. For more information, reference

for Setting of Point Operation is in the “Chapter 9.2.18.”

Содержание XBF-PN04B

Страница 1: ...Programmable Logic Controller Positioning Module EtherCAT XGB Series XBF PN04B XBF PN08B ...

Страница 626: ...Chapter 9 Functions BPS37 setup RS232 and PC connection BPS37 option board LED 9 193 ...

Страница 628: ...Chapter 9 Functions c Execute BPS37 set up program and enter the setting values as follows 9 195 ...

Страница 796: ...Appendix3 Dimension A3 1 Appendix 3 Dimension Appendix 3 1 Dimension of XBF PN04B PN08B ...