3.7.4.1 The SafeMove configurator app on FlexPendant ...............................

3.7.4.2 Configuration of SafeMove using Visual SafeMove in RobotStudio .......

3.7.5.1 Configuration of one PROFINET-base laser scanner (RobotWare 7.5 or

earlier) .......................................................................................

3.7.5.2 Configuration of one PROFIsafe-based laser scanner (RobotWare 7.6 or

later and PLC acting as Master) ......................................................

3.7.5.3 Configuration of two PROFIsafe-based laser scanners (RobotWare 7.6 or

later and PLC acting as Master) ......................................................

3.7.5.4 Configuration of one PROFIsafe-based laser scanner (RobotWare 7.10 or

later and OmniCore acting as Master) ..............................................

3.7.5.5 Configuration of two PROFIsafe-based laser scanners (RobotWare 7.10

or later and OmniCore acting as Master) ..........................................

3.7.5.6 Configuration of one SafetyIO-base laser scanner (RobotWare 7.6 or

later) .........................................................................................

3.7.5.7 Configuration of two SafetyIO-base laser scanners (RobotWare 7.6 or

later) .........................................................................................

3.7.5.8 Speed control strategies ...............................................................

Use cases of safety configurations .............................................................

Maintenance schedule and expected component life ...............................................

Specification of maintenance intervals ........................................................

Maintenance schedule .............................................................................

Expected component life .........................................................................

Cleaning the CRB 1100 ............................................................................

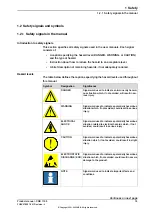

Inspecting the information labels ................................................................

Inspecting the robot cabling .....................................................................

Inspecting timing belts ............................................................................

Lubricating the cable package ...................................................................

Replacing the battery pack ........................................................................

Mounting instructions for sealings ..............................................................

Cut the paint or surface on the robot before replacing parts ............................

Replacing the upper cable package ...........................................................

Replacing the lower cable package ............................................................

Replacing the SMB unit ...........................................................................

Replacing the base .................................................................................

Replacing the swing ................................................................................

Replacing the lower arm ...........................................................................

Replacing the housing ..............................................................................

Replacing the extender unit and wrist .........................................................

6

Product manual - CRB 1100

3HAC078007-001 Revision: J

© Copyright 2021-2023 ABB. All rights reserved.

Table of contents

Summary of Contents for CRB 1100

Page 1: ...ROBOTICS Product manual CRB 1100 ...

Page 162: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 652: ...This page is intentionally left blank ...

Page 698: ...This page is intentionally left blank ...

Page 712: ...This page is intentionally left blank ...

Page 714: ...This page is intentionally left blank ...

Page 719: ......