Note

Action

xx1800002996

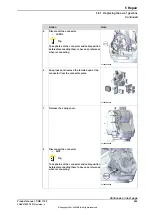

Remove the screws and washers.

4

Carefully lift out the motor.

5

xx1800002997

Remove the timing belt from its groove on the

motor.

6

Refitting the motor

Use these procedures to refit the axis-6 motor.

Refitting the axis-6 motor

Note

Action

Check that:

•

all assembly surfaces are clean and without

damages

•

the motor is clean and undamaged.

1

Continues on next page

540

Product manual - CRB 1100

3HAC078007-001 Revision: J

© Copyright 2021-2023 ABB. All rights reserved.

5 Repair

5.7.6 Replacing the axis-6 motor

Continued

Summary of Contents for CRB 1100

Page 1: ...ROBOTICS Product manual CRB 1100 ...

Page 162: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 652: ...This page is intentionally left blank ...

Page 698: ...This page is intentionally left blank ...

Page 712: ...This page is intentionally left blank ...

Page 714: ...This page is intentionally left blank ...

Page 719: ......