The parameters f_dest_address and f_source_address for the SDI are set to

3 and 2, respectively, and for the SDO are set to 5 and 4, respectively.

•

Make sure the address for the SDO signal is the first address of

SDO 8 bytes

slot.

•

Create variables.

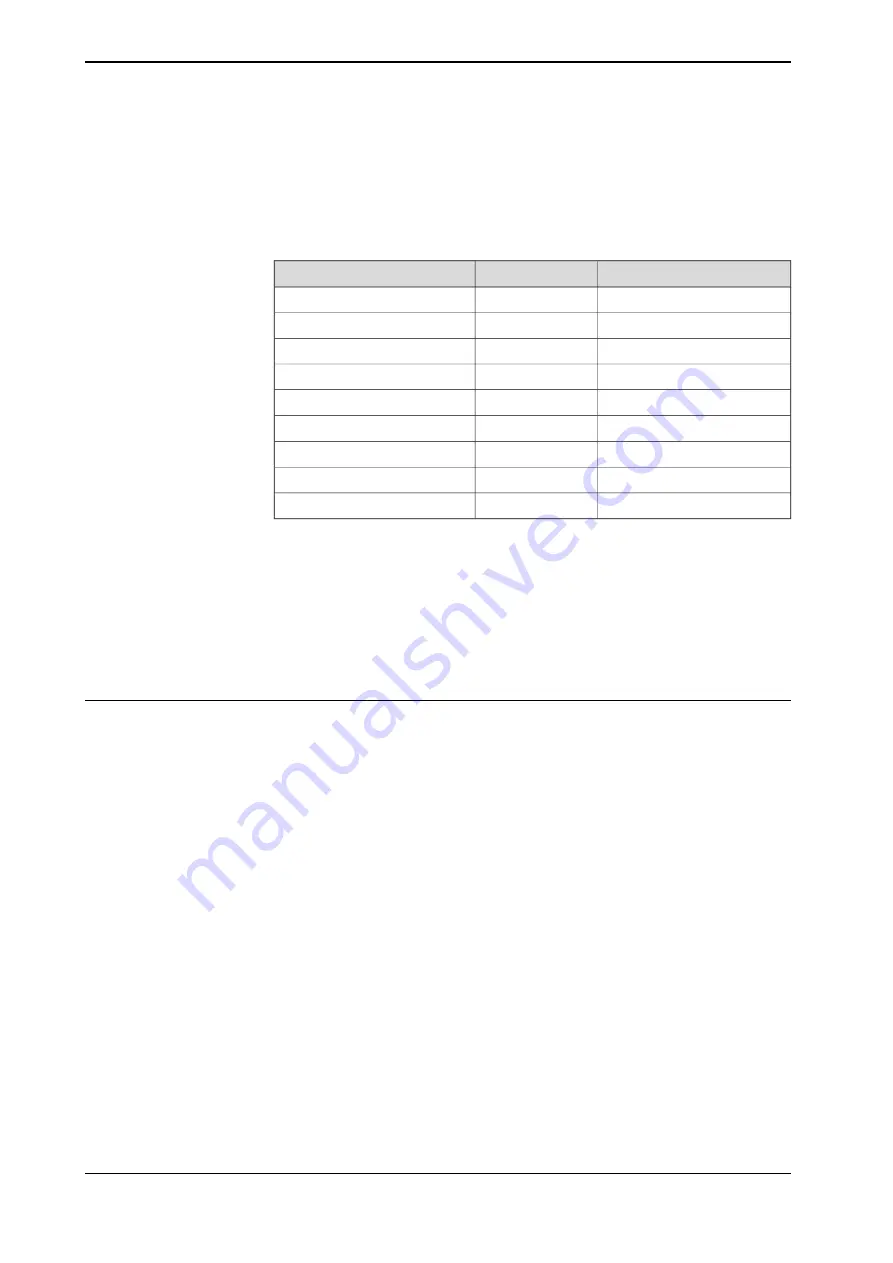

Example address

i

Type

Name

%I3.0

Bool

ProtectingTrigger

%I4.1

Bool

WarningTrigger

%I14.0

Bool

ProtectingTrigger1

%I15.1

Bool

WarningTrigger1

%Q68.0

Bool

ProtectingArea

ii

%Q68.1

Bool

WarningArea

iii

%Q68.2

Bool

SafetyCommunicationEnable

%Q3.0

Bool

ActivateScanner

%Q14.0

Bool

ActivateScanner1

i

%I3.

X

, %I4.

X

, %I14.

X

and %I15.

X

are the addresses of laser scanners; %Q68.

X

is the address

of the OmniCore controller.

%Q3.0 and %Q14.0 are for activating the monitoring cases of the laser scanners.

ii

Value of ProtectingArea depends on logic AND value of ProtectingTrigger and

ProtectingTrigger1.

iii

Value of WarningArea depends on logic AND value of WarningTrigger and WarningTrigger1.

•

Check the communication between the PLC and controller is well and activate

the laser scanner; set up the communication between the laser scanner, PLC

and OmniCore controller.

Configuring SafeMove

To enable SafeMove, perform the following procedure:

1 Log in the FlexPendant.

Make sure the user logged in have access grants to lock safety controller

configurations, safety services and software synchronization.

2 Tap

SafeMove

on the home page.

3 Tap

Load

in the pop-up message box to confirm loading of template SafeMove

configuration files.

The controller restarts.

4 After the controller is restarted, tap

Settings

on the home page.

5 Tap

Safety Controller

.

6 Tap

Synchronization

in the left pane.

7 Jog the robot to match the

Actual Positions

values with the

Sync Positions

values.

Make sure the values are the same.

8 Tap

Synchronize

.

132

Product manual - CRB 1100

3HAC078007-001 Revision: J

© Copyright 2021-2023 ABB. All rights reserved.

3 Installation and commissioning

3.7.5.3 Configuration of two PROFIsafe-based laser scanners (RobotWare 7.6 or later and PLC acting

as Master)

Continued

Summary of Contents for CRB 1100

Page 1: ...ROBOTICS Product manual CRB 1100 ...

Page 162: ...This page is intentionally left blank ...

Page 184: ...This page is intentionally left blank ...

Page 652: ...This page is intentionally left blank ...

Page 698: ...This page is intentionally left blank ...

Page 712: ...This page is intentionally left blank ...

Page 714: ...This page is intentionally left blank ...

Page 719: ......