5238-E P-86

SECTION 6 OFFSET FUNCTION

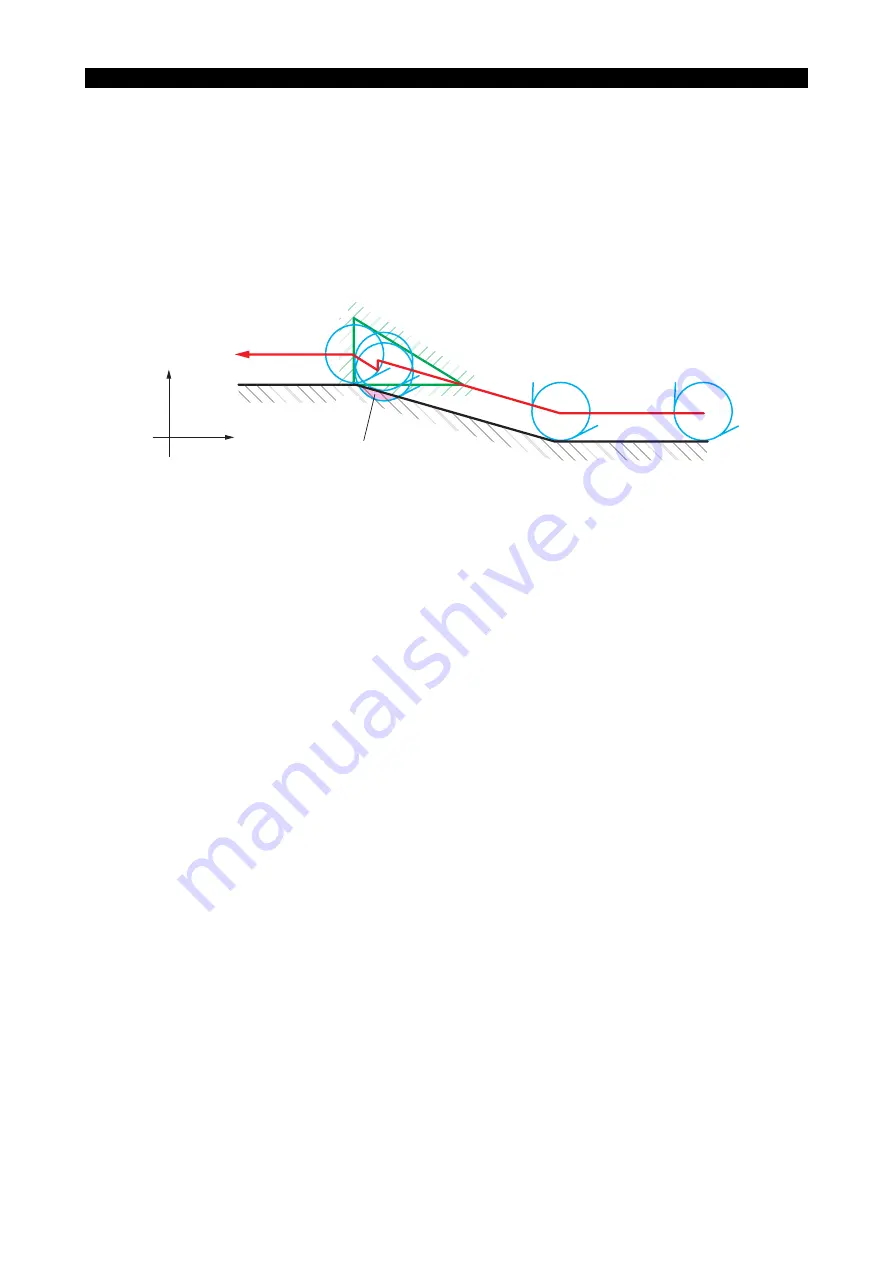

N3, N31 and N32 lie on the same straight line. From N3 to N31, the positioning is on the right hand

side of the line. Commands in block N32 position the cutting tool at the point where the tool nose R

is brought into contact with straight lines N31 - N32 and N3 - N4 on the right side of the direction of

tool advance. This causes the cutting tool to move not only in the X-axis direction but also in the Z-

axis direction although block N32 contains only an X word.

Such cutting tool movements leave an uncut portion as shown above.

Program 3

In this program, an attempt is made to eliminate the uncut portion caused by program 2.

LE33013R0300800120005

Program 3:

LE33013R0300800120006

When the control feeds the cutting tool from point N2 to point N3, it reads the position data of point

N31 as well as those of point N3. This permits the tool nose R to be positioned at the point where it

is in contact with the two straight lines N2 - N3 and N3 - N31.

After that, positioning is carried out at the point where the tool nose R comes into contact with the

two straight lines N3 - N31 and N31 - N32, when positioning is performed with the commands in

block N31. This moves the cutting tool in the -X direction although the commands in that block

specify tool movement in the +X direction. This is due to the positioning in block N3, where the tool

nose R goes beyond side N31 - N32.

Similarly, positioning of the cutting tool in block N32 is carried out at the point where the tool nose R

comes into contact with both straight lines N31 - N32 and N32 - N4. This also causes the cutting

tool to move in the direction opposite to the programmed direction. The result is overcutting.

Imaginary shape

Overcut portion

X+

N4

Z+

N31

N3

N32

N2

N1

N1

N2

N3

N31

N32

N4

G42

G00

G01

G01

X100

X120

X124

X120

Z100

Z80

Z40

Z42

Z20

F0.2

S1500

S1000

T010101

M03