5238-E P-221

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

•

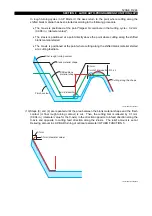

The LAP clearance amount (Lc) is set for the optional parameter (OTHER FUNCTION 1) in

units of

µ

.

LE33013R0301000290001

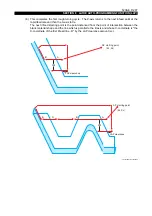

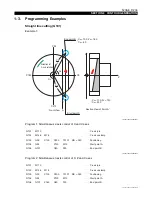

(5) The points designated in the blank material shape definition blocks are shifted by D in the

infeed direction. The cutting tool is fed at a cutting feedrate in the G01 mode from point A" to

point A’ (Za, Xh - D) which is obtained by shifting the first element coordinate (Za, Xh) of the

blank material shape definition blocks by D. Then, cutting is executed along H’ - G’ in the G01

mode. Here, the feedrate designated by the F command in the block for calling the rough

turning cycle is effective.

LE33013R0301000290002

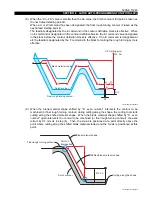

(6) When cutting reaches the point where the shifted blank material shape intersects the finish

contour, the cutting tool is relieved by 0.1 mm (radius value for the X-axis) in the direction

opposite to the infeed direction along the X-axis, and opposite to cutting feed direction along the

Z-axis. The relief amount is set for the optional parameter (OTHER FUNCTION 1) in units of

µ

.

When stock removal is designated in the program using the U or W command, the cutting tool is

relieved when cutting reaches the point where the shifted material shape intersects the final

rough turning contour.

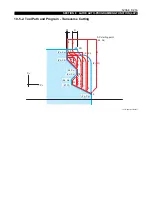

Blank material shape

Finish contour

AP starting point

(Zs, Xs)

(Zj, Xj)

(Zi, Xi)

(Zh, Xh) (Za, Xh)

D/2

LcA" (Za+Lc, Xh-D)

(Zc, Xc)

(Zb, Xb)

(Za, Xa)

Point A after change

Point A before change

G

N

D/2N'

G'

M'

M

L'

L

D/2

K

J

J'

K'

D/2

A

I

H

I'

H'

D/2

A'

A"

Lc

U/2

W