5238-E P-186

SECTION 8 LATHE AUTO-PROGRAMMING FUNCTION (LAP)

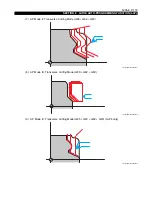

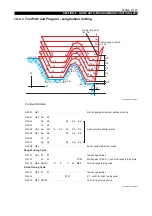

(5) Cutting is performed in the G01 mode up to point B where the straight line parallel to the Z-axis

and passing through point A intersects the final contour of the rough turning cycle. The feedrate

in this cutting cycle is the one selected by the F word when the rough turning cycle was called

out.

LE33013R0301000140001

(6) After point B has been reached, the final contour of the rough turning cycle is cut up to the point

whose X coordinate is Xb + D. If G80, indicating the end of contour definition, is encountered

before this point is reached, the final rough turning contour is cut up to the point specified in the

block preceding the G80 block.

The feedrate in this cut is as specified by E, which is designated in a contour definition program.

If no E word is designated in the corresponding contour definition program, the one designated

last becomes effective. When an E word has not been specified, the feedrate specified when

calling out the rough turning cycle becomes active.

LE33013R0301000140002

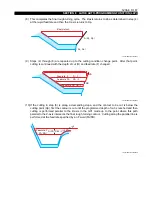

(7) After the completion of the cutting explained in (6), the cutting tool is relieved from the

workpiece in the direction opposite the infeed direction along the X-axis, and toward Zs along

the Z-axis, by 0.1 mm on each axis (diameter value in the case of the X-axis).

The relief amount is set at Relieving amount in LAP-BAR turning of optional parameter (OTHER

FUNCTION 1) in units of

µ

.

LE33013R0301000140003

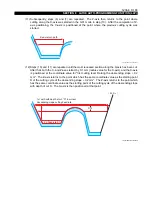

Final tool path in rough cut cycle

Final contour

B

W

G01

A ( Zp, Xp )

( Za, Xa )

( Za + W, X a + U )

U / 2

B

D / 2

0.1 mm

0.1 mm

D / 2