5238-E P-89

SECTION 6 OFFSET FUNCTION

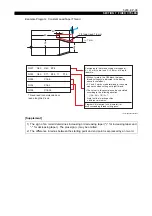

[Supplement]

1) If either the X- or Z-axis exceed its soft-limit, a "Limit Alarm" results.

2) During the tool nose radius compensation mode, commands that do not cause axis motion,

although dimension words are present, (zero offset by G code for instance, or thread cutting

fixed cycle (G31, G32 and G33)) cannot be specified.

3) To activate the tool nose radius compensation mode from LAP mode operation, designate G41

or G42 in the block preceded by the one containing G81 or G82 in which the cutting dimensions

in the LAP are specified. In LAP mode operation, tool nose radius compensation is active both

in rough and finish cut cycles.

Be sure to enter G40, which cancels the tool nose radius compensation mode, before

specifying the end of LAP contour designation code G80.

4) While in the tool nose radius compensation mode, the same point should not be commanded

repeatedly. However, one block that does not contain axis motion commands can be

programmed; the control is designed to accept such block.

5) At the start up of tool nose radius compensation mode, the control starts execution of the

commands after it read in the commands in the successive two blocks. Therefore, pressing the

CYCLE START button in the MDI mode after entering the commands for one block cannot start

machine operation.

6) Incremental commands (G91) can be provided in the tool nose radius compensation mode.